17 October, 2014

1/32 Controller

The name

Difalco in our hobby is widely known. When you say you have a Difalco,

it means you have one of the best controllers our hobby has to offer in

your hands. Recently a new line has been introduced targeting the

1/32nd scale racer, that balances the quality and performance the brand

is known for along with a lower price.

I

have been in this hobby a long time and this is my first Difalco. Why

is that? Because for years the brand focused more on the commercial

track enthusiast and the price tag was more than I could justify for my

simple home use. I had used a few over the years and really liked how

they felt and responded, but there were other options for my track that

seemed to make more sense.

Until

now. Enter the DD300 Neo 1/32. This is the 17 band version which I feel

is the best combination for my use. I

don't need all the higher end features the more advanced controllers

offer. I am not into heavy competition.

Just a simple home racer who wants a decent range of

sensitivity, along with braking I can adjust.

Opening

the box and grabbing hold of this controller was a treat. It felt good

in my hands because it used the tried and true PARMA grip that I have

grown used to over the years.

TECH SPECS

* 17 Bands:

The 17 band design provides smoother, more precise control than

comparably priced controllers.

* Flexibility: Unlike resistor based controllers which are designed to work for a very narrow range of applications, the Difalco 17-band Neo controller will work with virtually any 1/32 motor.

* Adjustable Braking: Provides a wide range of adjustment to match car, track and driver characteristics for optimum performance.

* Adjustable Sensitivity: Provides a wide range of adjustment to match car, track and driver characteristics for optimum performance.

* Ball Bearing Trigger With Threaded Trigger Pin: Designed for heavy-duty use and long life. The ball bearings provide silky smooth trigger action resulting in more precise control. They will not wear like standard oilites that induce trigger side play and cause poor wiper button contact. The adjustable pivot nut means even after years of heavy use your controller will never develop trigger "slop" like other brands.

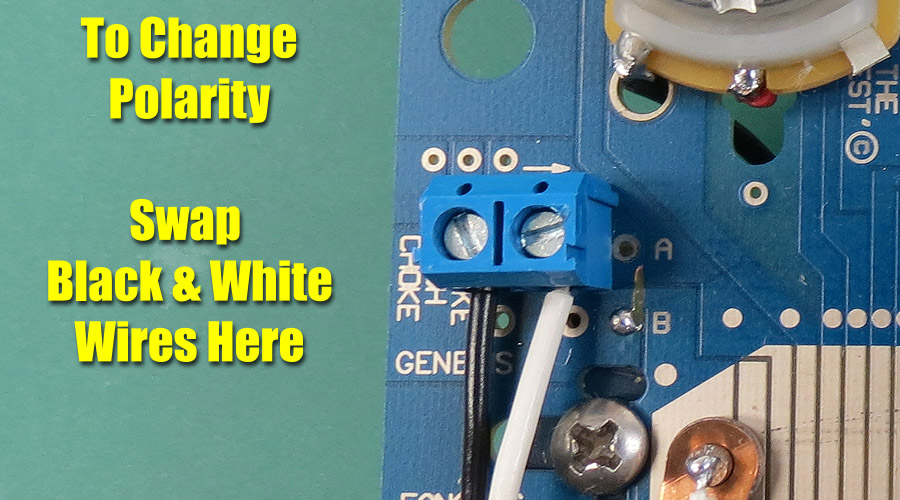

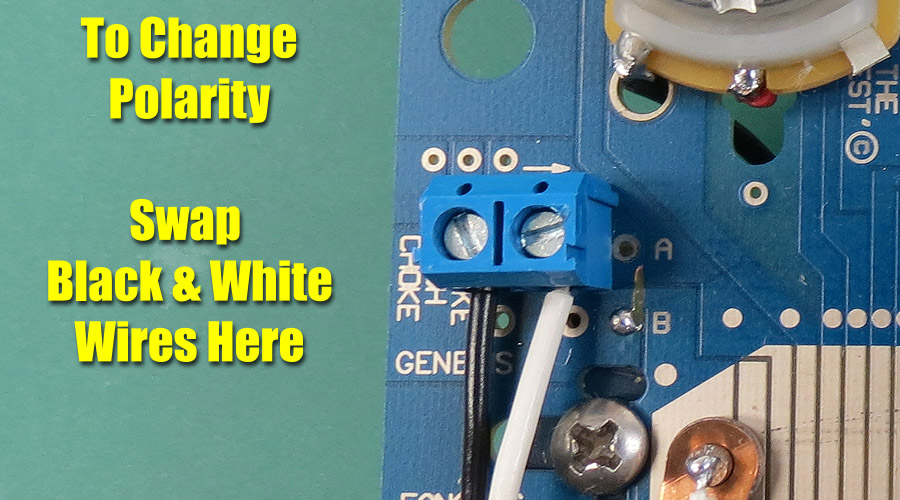

* Dual Polarity: The Neo DD300 is wired for positive polarity at the factory; however, this can be easily changed with a small screwdriver by the user if desired.

* Design: All Difalco Neo controllers are built on a fiberglass frame with a large floating brass power contact (for maximum power transfer), stainless steel hardware, and heavy duty wire. The circuit board is nickel plated and will not corrode like plain copper designs.

* Ergonomics: Difalco Neo controller feature a sturdy, comfortable Parma handle that can be used for extended periods of time without causing pain or fatique. This is the same handle used on the higher-end Genesis controllers.

* Ease of Maintenance: With minimal user maintenance, your Difalco Neo controller will give you many years of trouble-free service. Clearly written maintenance instructions are included. The open frame design makes routine cleaning and maintenance quick and easy.

* Service and Support: Complete troubleshooting instructions are included so in the unlikely event a problem should occur racers can quickly diagnose and fix most problems with readily available, inexpensive repair parts. No need to send your controller back to the factory or another country. In the event you need assistance, Jim at Difalco Design will be there with his 45 years of slot racing knowledge for advice or to service your controller.

* Flexibility: Unlike resistor based controllers which are designed to work for a very narrow range of applications, the Difalco 17-band Neo controller will work with virtually any 1/32 motor.

* Adjustable Braking: Provides a wide range of adjustment to match car, track and driver characteristics for optimum performance.

* Adjustable Sensitivity: Provides a wide range of adjustment to match car, track and driver characteristics for optimum performance.

* Ball Bearing Trigger With Threaded Trigger Pin: Designed for heavy-duty use and long life. The ball bearings provide silky smooth trigger action resulting in more precise control. They will not wear like standard oilites that induce trigger side play and cause poor wiper button contact. The adjustable pivot nut means even after years of heavy use your controller will never develop trigger "slop" like other brands.

* Dual Polarity: The Neo DD300 is wired for positive polarity at the factory; however, this can be easily changed with a small screwdriver by the user if desired.

* Design: All Difalco Neo controllers are built on a fiberglass frame with a large floating brass power contact (for maximum power transfer), stainless steel hardware, and heavy duty wire. The circuit board is nickel plated and will not corrode like plain copper designs.

* Ergonomics: Difalco Neo controller feature a sturdy, comfortable Parma handle that can be used for extended periods of time without causing pain or fatique. This is the same handle used on the higher-end Genesis controllers.

* Ease of Maintenance: With minimal user maintenance, your Difalco Neo controller will give you many years of trouble-free service. Clearly written maintenance instructions are included. The open frame design makes routine cleaning and maintenance quick and easy.

* Service and Support: Complete troubleshooting instructions are included so in the unlikely event a problem should occur racers can quickly diagnose and fix most problems with readily available, inexpensive repair parts. No need to send your controller back to the factory or another country. In the event you need assistance, Jim at Difalco Design will be there with his 45 years of slot racing knowledge for advice or to service your controller.

The

last part means a lot. Jim has been racing since the 60's and making

controllers since 1990. That is good enough for me.

CLOSER LOOK

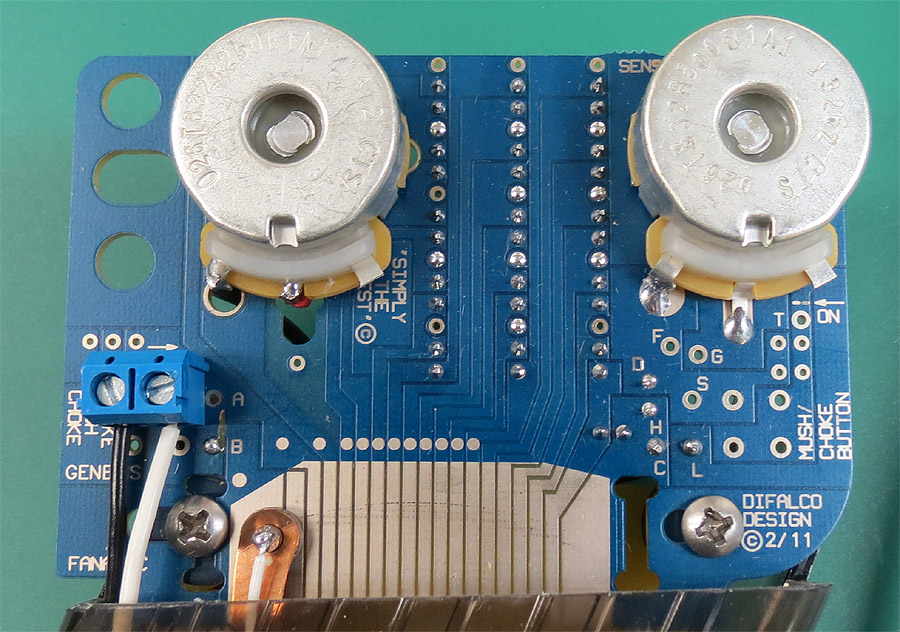

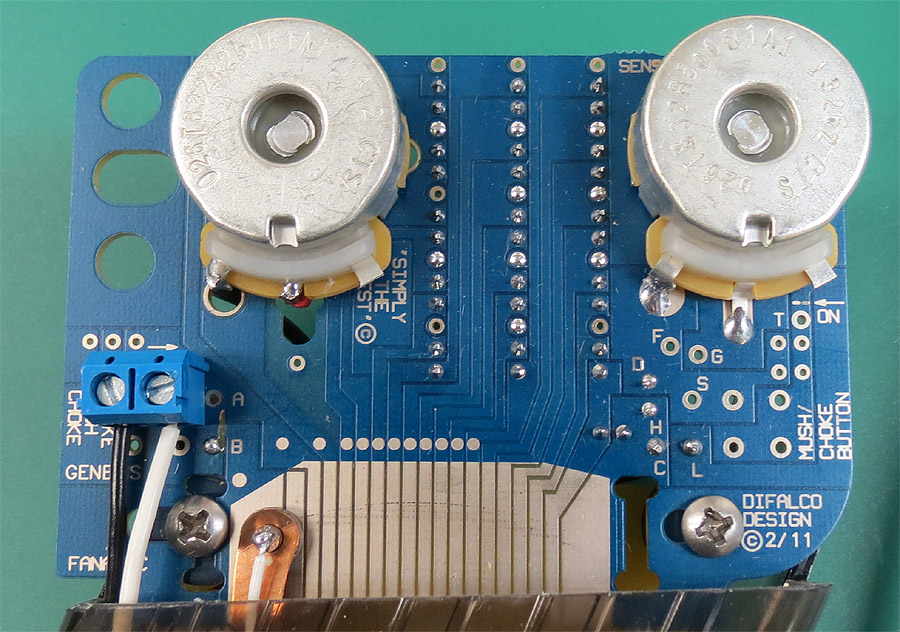

The

first thing that catches your eye is the tall circuit board coming out

of the top and the dual control knobs. Very straight forward approach

and I like it.

I really like the fact the wiper/contact is easily accessible for cleaning. It' amused me because I have been slicing my standard Parma Econo controllers for year just for this purpose. Now there is no need to take the unit apart for that quick clean up.

What I like is the visible numbering system for the knobs. It clearly shows you which way to turn the knobs to increase or decrease the action. Not all controllers have that. I can't count how many times people have asked me "which way is what?" on my PM controllers. No dilema here.

"What is that thing on the cord?" I hear that a lot about controllers. Perfectly honest question because not all enthusiasts out there have used or seen controllers like this. The top part is simply a heatsink module. It does what it's namesake says it does. It keeps things cooler. When the juice starts flowing it helps cool the transistor.

There is a diode in place near one end of the heatsink. It is there to protect the transistor located on the underside of the heatsink in the event you hook the controller up the wrong way, or if you hook it to a track that is wired for a different polarity than the controller is set for. It's best to keep this module assembly away from track terminals to avoid damage.

I really like the fact the wiper/contact is easily accessible for cleaning. It' amused me because I have been slicing my standard Parma Econo controllers for year just for this purpose. Now there is no need to take the unit apart for that quick clean up.

What I like is the visible numbering system for the knobs. It clearly shows you which way to turn the knobs to increase or decrease the action. Not all controllers have that. I can't count how many times people have asked me "which way is what?" on my PM controllers. No dilema here.

"What is that thing on the cord?" I hear that a lot about controllers. Perfectly honest question because not all enthusiasts out there have used or seen controllers like this. The top part is simply a heatsink module. It does what it's namesake says it does. It keeps things cooler. When the juice starts flowing it helps cool the transistor.

There is a diode in place near one end of the heatsink. It is there to protect the transistor located on the underside of the heatsink in the event you hook the controller up the wrong way, or if you hook it to a track that is wired for a different polarity than the controller is set for. It's best to keep this module assembly away from track terminals to avoid damage.

Hook-Up &

Polarity

This is a dual polarity controller that comes from the factory wired for positive polarity. Positve polarity (positive side of power supply to power terminal) means an ohmmeter shows a + sign when measured between the track's power terminal and the brake terminal. A negative polarity track will show a - symbol when measured this way.

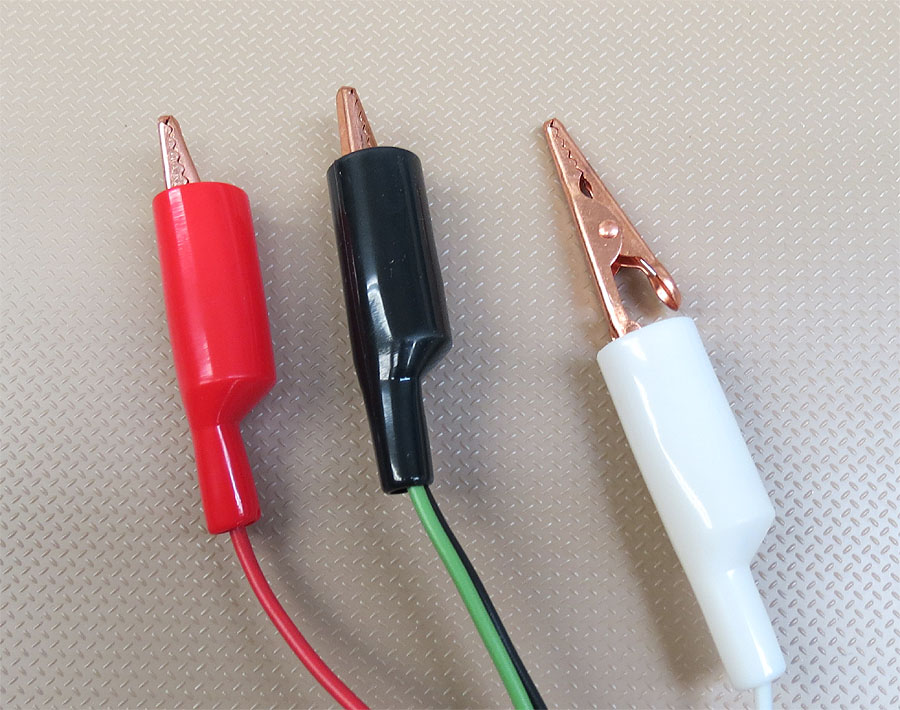

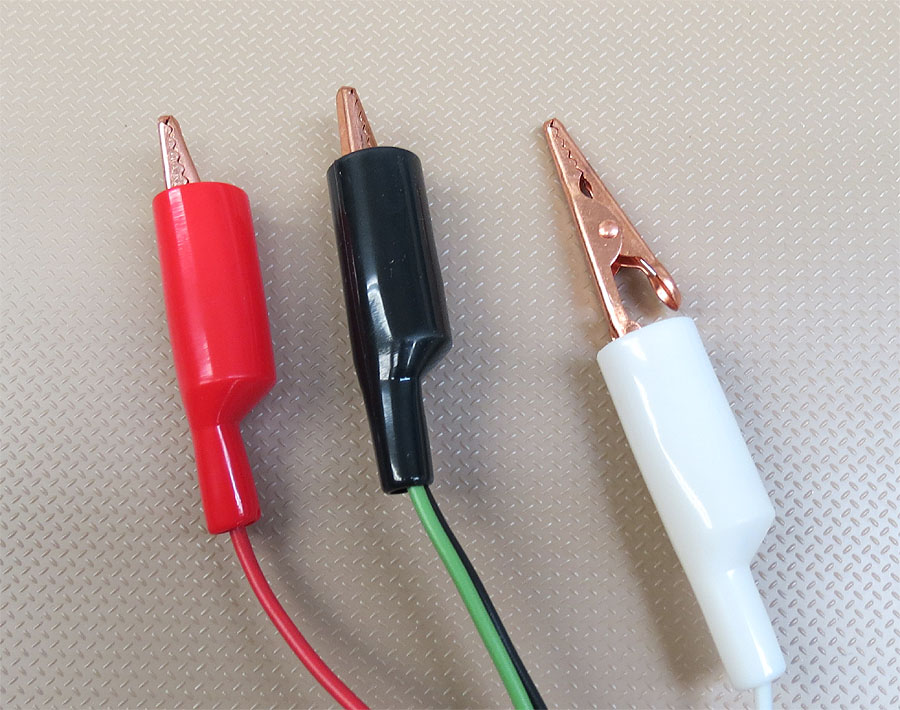

To check the track for polarity, hook up the black and white clips ONLY of the controller to the lane. Without pulling the trigger, place a car on the track and hold the rear in the air. If the car DOES NOT get power (wheel spin) then you are on the correct positve polarity track. Hook up your red wire and start racing.

To use the controller on a NEGATIVE polarity track, you must swap the the 2 wires at the blue terminal block on the controller. DO NOT just exchange black and white clips at the track terminals.

Our tracks are a standard 3 bolt hook up so I chose the alligator clip style connection.

This is a dual polarity controller that comes from the factory wired for positive polarity. Positve polarity (positive side of power supply to power terminal) means an ohmmeter shows a + sign when measured between the track's power terminal and the brake terminal. A negative polarity track will show a - symbol when measured this way.

To check the track for polarity, hook up the black and white clips ONLY of the controller to the lane. Without pulling the trigger, place a car on the track and hold the rear in the air. If the car DOES NOT get power (wheel spin) then you are on the correct positve polarity track. Hook up your red wire and start racing.

To use the controller on a NEGATIVE polarity track, you must swap the the 2 wires at the blue terminal block on the controller. DO NOT just exchange black and white clips at the track terminals.

Our tracks are a standard 3 bolt hook up so I chose the alligator clip style connection.

TESTING

I tested models that

had a wide variety of motors. This controller is designed for the

normal "homeset" motors we have primarily in 1/32 and that is all I

use. Aside from the occasional old school motors of course. The

selection ranged from the 40,000 K H&R Lightining II down to

the MT-1 14 K classic motor and just about everything in between.

What can I say? This controller works and works VERY well. The sensitivity control is what I look for most and I could dial down the power to get the trigger action I preferred easily. Braking the same. I could not tell a huge difference on some motors in braking department, but that is due more to the motor itself than the controller. That trigger action is really nice due to the ball bearing.

What can I say? This controller works and works VERY well. The sensitivity control is what I look for most and I could dial down the power to get the trigger action I preferred easily. Braking the same. I could not tell a huge difference on some motors in braking department, but that is due more to the motor itself than the controller. That trigger action is really nice due to the ball bearing.

Final

Thoughts

All of this sounds

great, but what about the price? As of this

writing Slot Car Corner has them for $129.50. That is fair enough for a

controller that offers what this one does. I think Difalco has made a

great controller for the 1/32nd scale enthusiast. In this price range I

would say it's a tough one to beat.

-Harry

-Harry

As always, feel free to contact me about this article or the hobby in general.

Sponsored By The Staff At Slot Car Corner & Difalco Design

Copyright © 2014 HomeRacingWorld.com All Rights Reserved