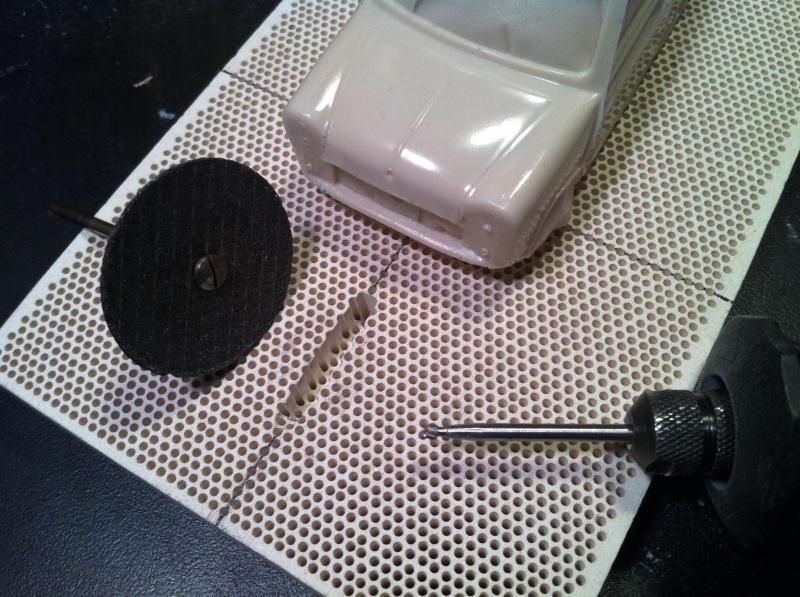

I took the plunge and cut into the ceramic chassis block. CAUTION: I used a facemask, and carefully swept up the debris - I don't know if there are any fibrous materials but no need to take chances. This stuff is soft an cuts readily!

I like to set a guide up with the chassis I am building to confirm I've left enough clearance to axles, support blocks, etc. After establishing centerlines with a finepoint sharpie along a row of existing holes, I marked off a typical slot location. Then I drilled two holes (enlarging existing holes), one at each end of the slot. I then used my largest Dremel cut off wheel to carefully slot mostly between them. After, I used a small dental tip to square up the corners. You're eyes will be swimming looking closely at all those holes :roll:

I stuck some rubber feet on the bottom to keep it from sliding around on the bench. My RetroJig is getting there!

JT