Page 1 of 1

My inline method

Posted:

Mon Jul 13, 2015 7:27 amby HomeRacingWorld

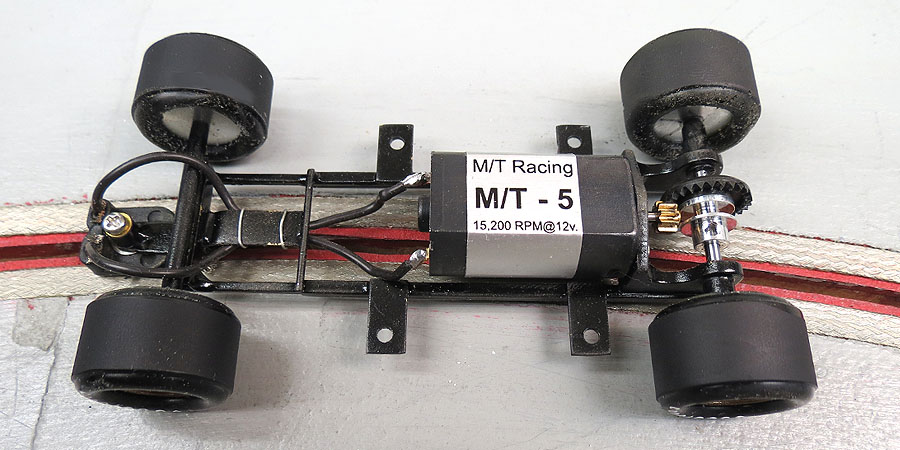

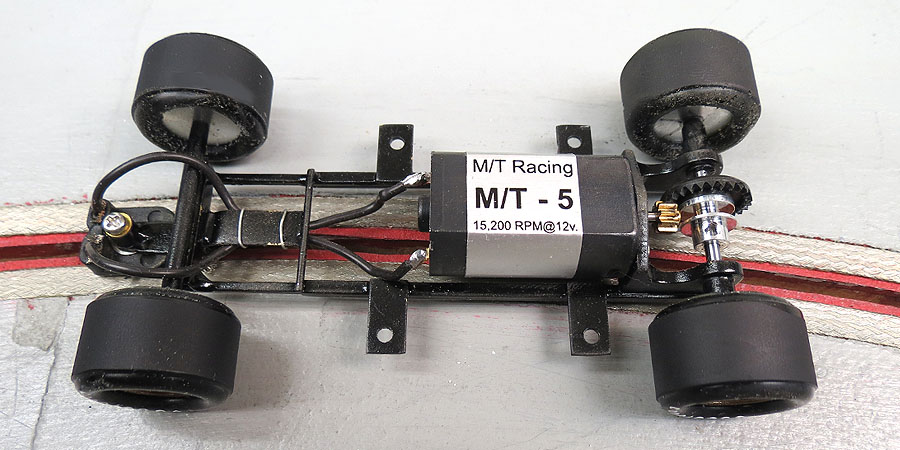

So the subject has been brought up about inline tuning and the ease (or lack thereof) of setting one up.

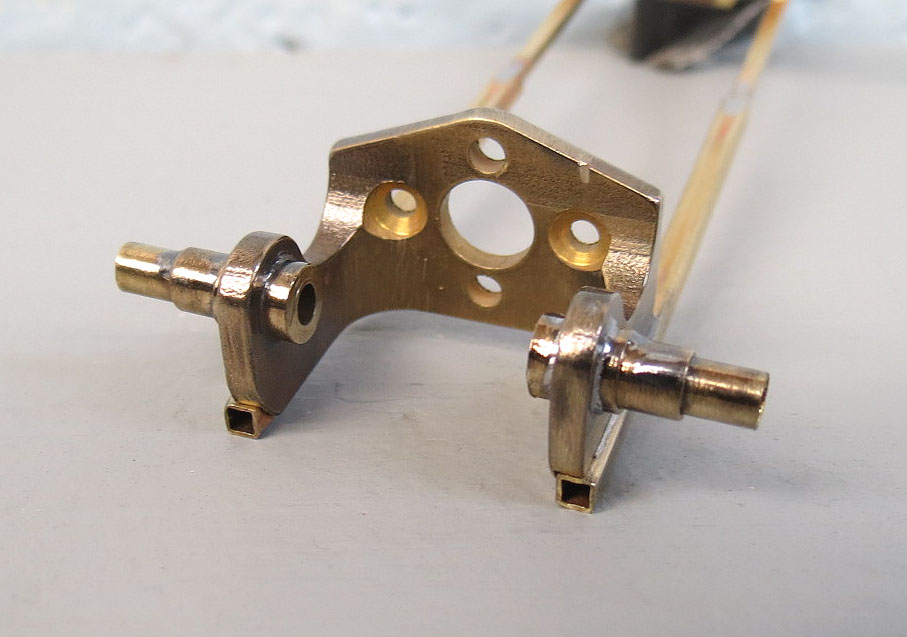

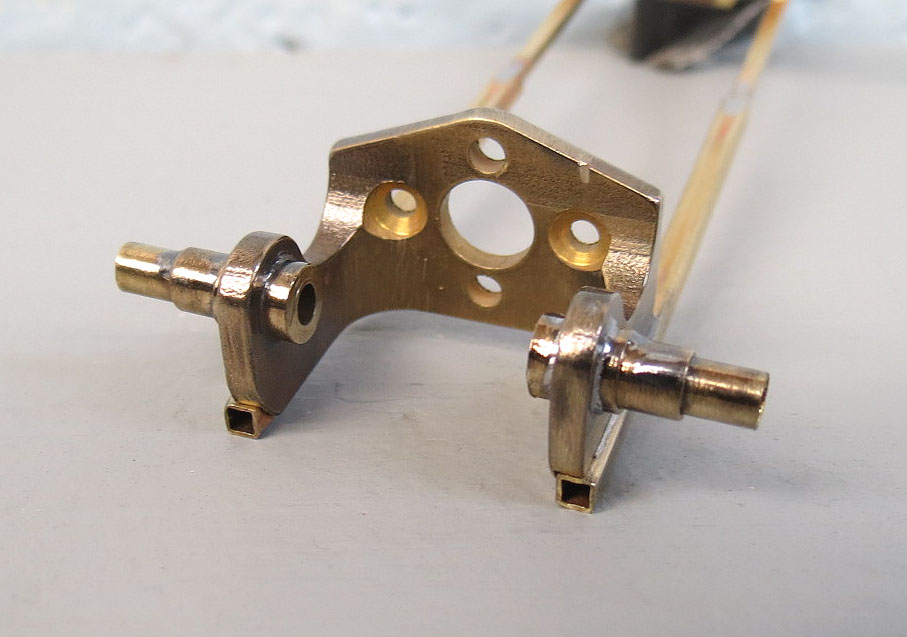

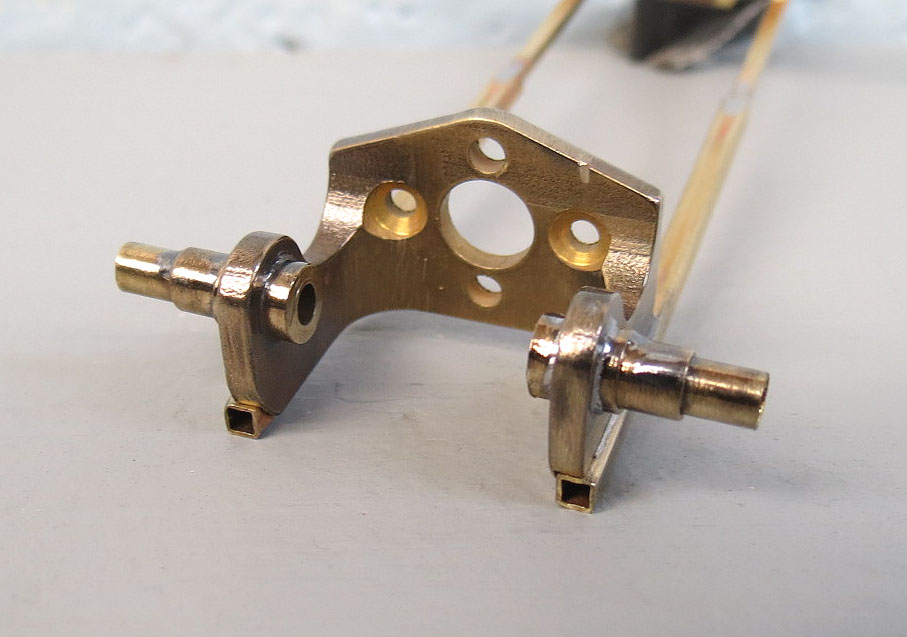

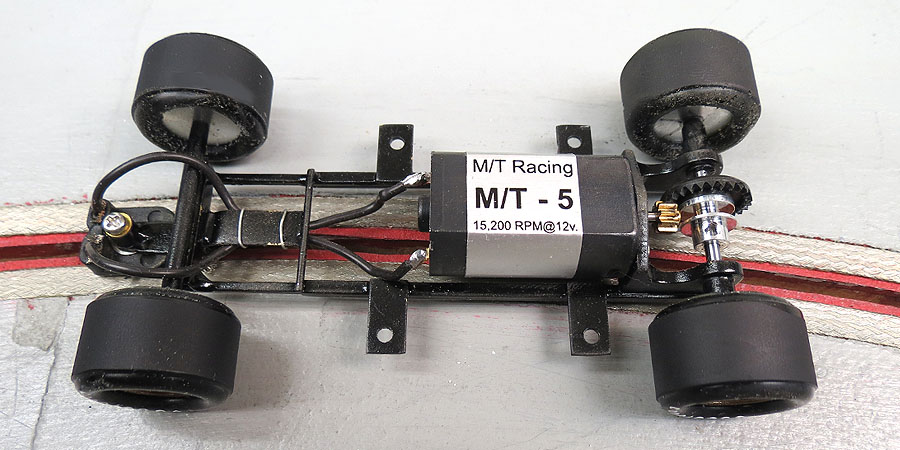

In my builds I measure and cut the tubing the length it needs to be to set the width of the rear wheels. This sets my side to side freeplay and no need for the motor shaft to rest inside the boss (groove) of the crown. My freeplay is set using the wheels. I adjust the wheel on one side until I have a freely spinning assembly.

Does the longer tubing on each end cause more friction than a bushing? Sure it does. Is how MUCH it causes that critical in my building? No.

I will run a axle through this with my drill and some polishing compound. When I am finished "honing", I can tilt this chassis and the axle will fall out faster than I can catch it. That is about as good as it gets to me.

I use this method because it's simple for me. No other reason. If I decide I want one of the wheels to sit a little wider, I use a small shim that SCC sells. If I need it to come inside, I use a flat file to reduce it. Some fine grit sandpaper deburrs the edges just fine.

The difference of this setup and using standard bushings with axle collars or spacers haven't cost me any wins. :)

So I am not disputing anything here. Also not saying my method is the way anyone should do it. Just how I like it. :)

Re: My inline method

Posted:

Mon Jul 13, 2015 9:26 amby waaytoomuchintothis

When you think about it, you have to solder in the bronze insert bushings anyway, so why not do it this way? In the 60s, lots of folks did it this way. I saw it had been done once with steel tubing, but he was one of the grown men slot racers, I was in my teens and didn't know him. He had also bent and bored his own motor mount for it to go through. In those days we tried to make the lowest parts of the chassis as heavy as was practical, and the body was like airweight. Not a lot of good scale work and detail in those days where I was. They were faster, but I like scale racing today much more than those commercial track blurs.

Re: My inline method

Posted:

Mon Jul 13, 2015 12:30 pmby Gameover

Ya look at my stats im always at the bottom lol. I like my cars to look real. I enjoy looking at them. I use the same method ad harry but use square tubing and solder my motor to the chassis 90% of the time :)

Re: My inline method

Posted:

Mon Jul 13, 2015 12:51 pmby bill from nh

Harry, if you were ever concerned about rear axle friction (which you aren't), you could always make the biggest diameter tube the longest one & the middle & the smallest ones something like 1/8"-1/4" long. Essentially, you'd still be using the same three tube diameters but with the pieces getting shorter as the tubing diameter gets smaller.

Re: My inline method

Posted:

Mon Jul 13, 2015 1:13 pmby HomeRacingWorld

Yes sir, excellent point. I might try that.

Re: My inline method

Posted:

Mon Jul 13, 2015 1:20 pmby noddaz

I need to do this...

Really I do...

Thanks for all these build tips and helpful hints

Scott

Re: My inline method

Posted:

Mon Jul 13, 2015 4:31 pmby waaytoomuchintothis

As far as I am concerned, that cast bracket from Prof Motor is the bee's knees. The rabbet for the square tubing is only part of the precision work in that thing. Its one of those things I keep as a stock item in my slot car cabinet.

Johnny is correct again, regarding the attitude around here. Like several others on HRW, I go back to the earliest days of Aurora, the earliest days of commercial slot car tracks, home routed tracks, and slot car clubs. Except for the best clubs, a few magazines (Model Car Science, Car Model, Model Car and Track, and others), the rule was to withhold information, silly secretiveness. I distinctly remember guys who wouldn't tell me about articles that schooled them in these mags.

Its like graduate schools; some are easy to get into- and they try all the time to throw you out, then there are the ones that are hard as hell to get into and they will do anything to keep you in the program (those are the real educators). The real educators are constantly giving you more and more to learn, the crap elitists withhold the knowledge, making you waste time and effort. One produces a person who adds to the body of knowledge; the other is an elitist academician like the twerps who produced him. Life is full of parallels and inferences, I guess. The bottom line is-- I like HRW, and I know whereof I speak. How about that!?!

Re: My inline method

Posted:

Mon Jul 13, 2015 5:53 pmby Audi1

I like the idea of not having the motor armature sit in the crown gear groove; there's no chance of armature/crown friction with that set up. I think that's how this topic got started; we (at least some of us) were talking on another thread about getting away from the friction that can be associated with the motor armature sticking into the crown groove (using the armature shaft to set the rear axle assembly).

I use spacers between the crown gear and the inside bushing faces to position the crown; just another way of doing it. I also use plastic chassis for my builds; at least I have so far. I can feel a brass chassis coming, though - probably soon.

If you can hold the chassis vertical on its side and drop the rear axle through the assembly that you've constructed, then I'd say that's probably as good as you're going to get from a friction reduction standpoint; almost regardless of the assembly that you have.

Thanks for posting this how-to, Harry.

Allan

Re: My inline method

Posted:

Mon Jul 13, 2015 6:12 pmby TuscoTodd

Agreed! That is part of what makes this place great!!!

:D

Re: My inline method

Posted:

Tue Jul 14, 2015 9:46 amby strangebrew

Only thing I have to add is to be carefull if you run an axle in a drill through the tubing.

Being dissimilar metals they gain heat at different rates & too much friction can cause the axle to seize

in the tubing. (Speaking from experience)

Re: My inline method

Posted:

Tue Jul 14, 2015 9:55 amby HomeRacingWorld

Re: My inline method

Posted:

Tue Jul 14, 2015 10:50 amby strangebrew

A wheel on one of the sportsmen I sent to Harry's for the proxy WILL NEVER COME OFF THE AXLE AGAIN

because I forgot what every machinist knows. (see above)