Page 1 of 5

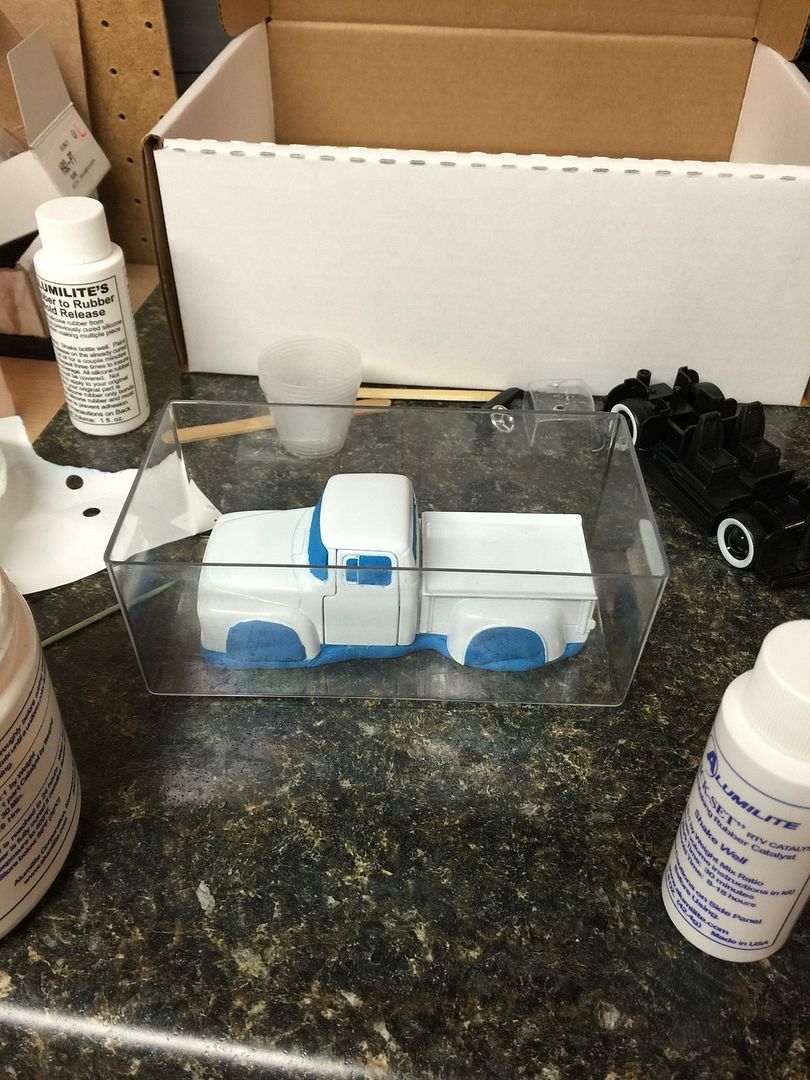

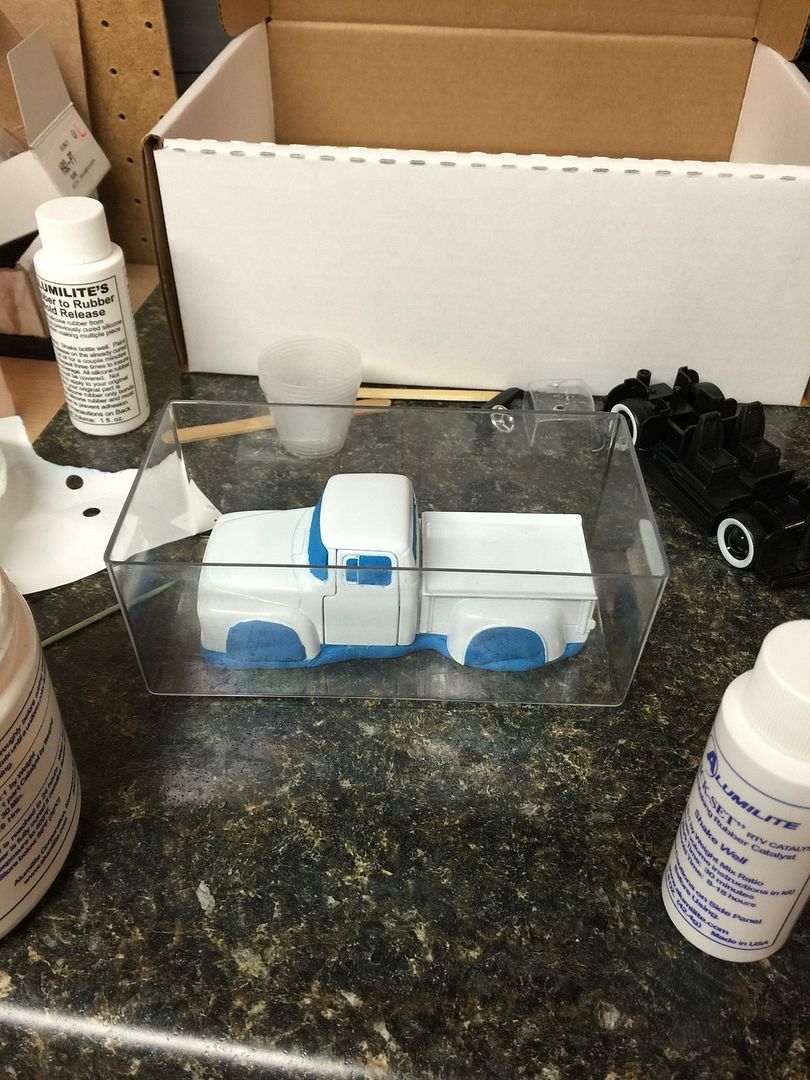

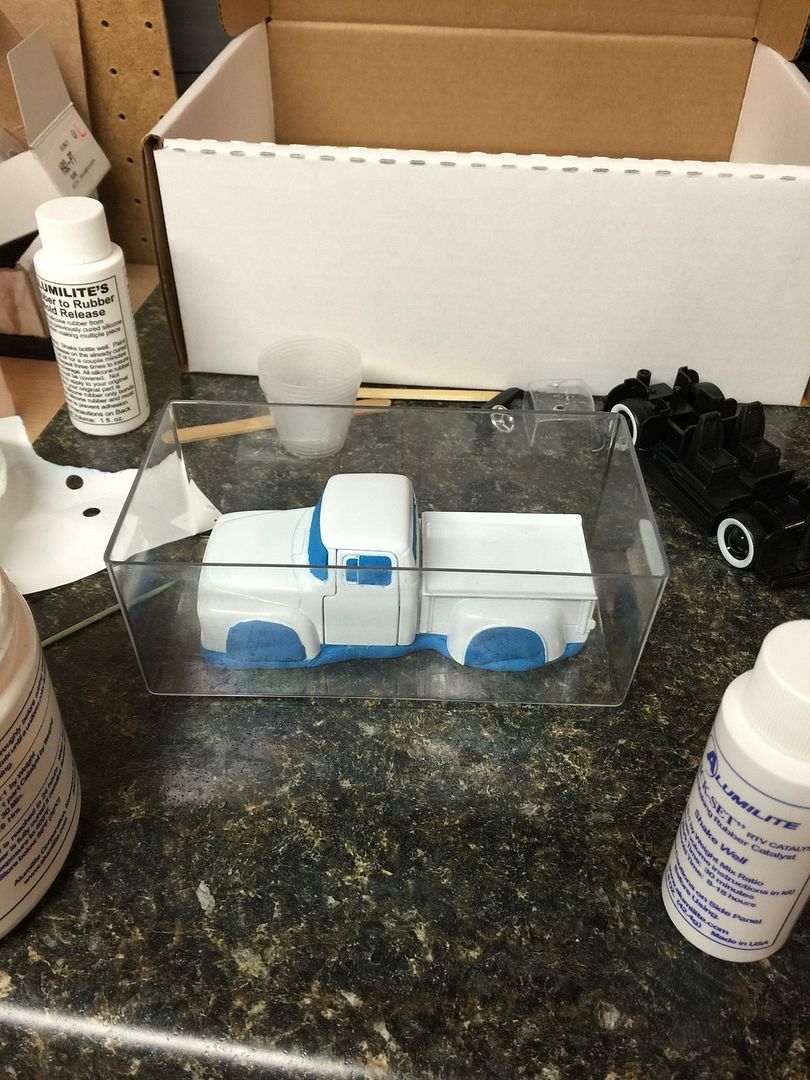

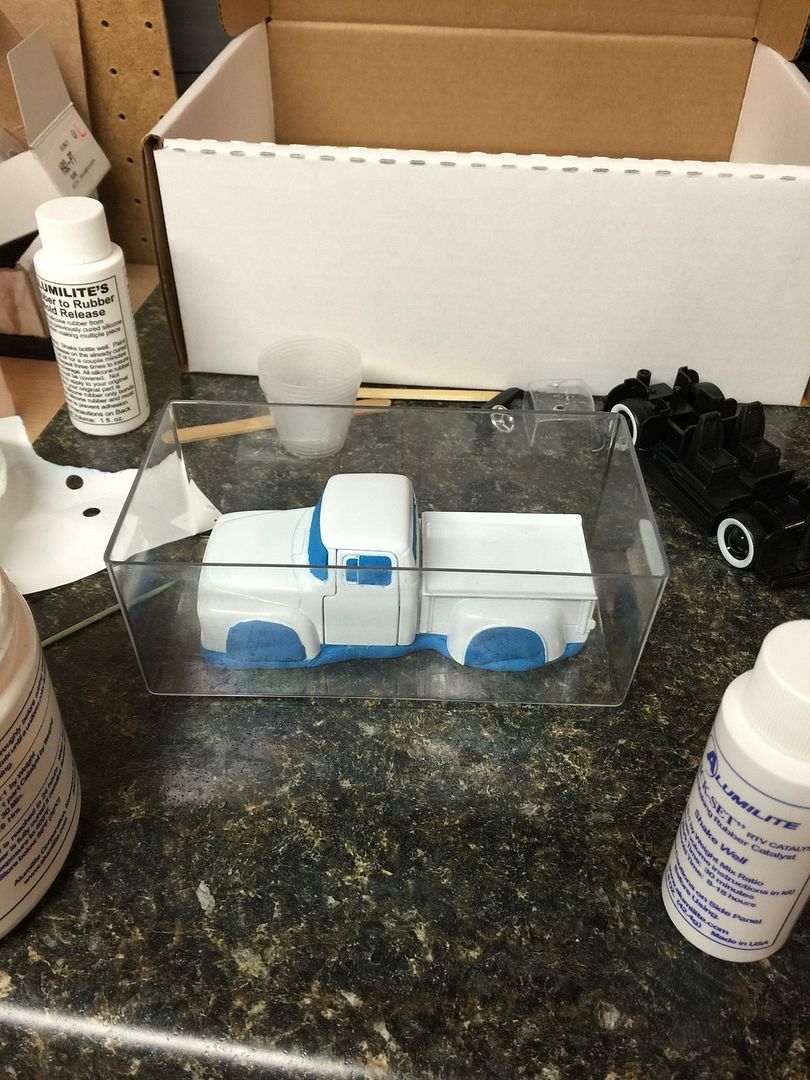

Casting 1956 ford f100 mold completed

Posted:

Tue Aug 18, 2015 7:57 pmby Gameover

Well i jumped in! Im casting my own stuff. First up my all time favorite vehicle ever!!

A 1956 ford f100

Re: Casting

Posted:

Tue Aug 18, 2015 8:02 pmby HomeRacingWorld

Good luck Steve...we are watching :)

Re: Casting

Posted:

Wed Aug 19, 2015 5:42 amby Ky.Slot Racer

Nice start up project Steve, Good luck with your efforts.

Suggestion,

Since it looks like your using clay,undercut your openings with a small screwdriver or clay tool ...wheels wells, windows. Also at the bottom body line, this will leave you a nice clean edge to trim to when removed from the mold.

Re: Casting

Posted:

Wed Aug 19, 2015 7:08 amby mattb

Another tip, allow at least 1/2 to 1 inch of clay below the body. Your inner plug will force resin out of the mold if you don't have that 1/2 inch or so of space above the cavity. After you cast a few, you may find a couple places that the resin doesn't easily flow to and there will be air pockets. Your best bet then is to cut some vents to allow the resin to more easily move into those parts of the mold. Two coats of silicone to silicone mold release before you do the inner plug, allow to dry at least 12 hours. Coat the whole outer mold, even where the body sets.

When you pour, rotate your mold so the resin covers the whole inside, then slowly push the inner plug in position.

If you want to skip the mold release inside your mold, a generous coating of talcum powder will work. Liberally coat the inside them blow out the excess. I will release easy and will leave a surface that is great for paint adhesion.

Plenty of guys on here that can help you along the way.

Re: Casting

Posted:

Wed Aug 19, 2015 9:38 amby Gameover

thanks guys.... im learning :). ran short on silicone so will stop by hobby lobby tonight on my way home. should have a body by friday :)

Re: Casting

Posted:

Wed Aug 19, 2015 1:25 pmby mattb

Which Alumilite are using? Their fast cure makes a nice outer mold while the slow cure makes a really flexible inner that can be removed without tearing it up. that stuff is hard to tear and so soft that you can squeeze it together easy to reove it from inside a body.

Re: Casting

Posted:

Wed Aug 19, 2015 2:21 pmby munter

I would also fill the door shut lines and then re-scribe them....or the silicone will get in there and hold your body then rip or tear where you don't want it to.

Re: Casting

Posted:

Wed Aug 19, 2015 2:27 pmby Gameover

im using the alumilite starter kit with the fast set harder stuff.

munter thats what btaylor also told me last night on the phone.

Re: Casting

Posted:

Wed Aug 19, 2015 11:08 pmby munter

The silicone will find its way into every nook and cranny so btaylor was right. I on the other hand never got the phone call and had to learn by error and trial...more error than a lot of anything else.

Re: Casting

Posted:

Thu Aug 20, 2015 2:33 amby Dangermouse

ah but we are all thankful for those errors John - as you now produce some excellent bodies :)

I will be following this thread

cheers

David

Re: Casting

Posted:

Thu Aug 20, 2015 8:04 amby mattb

Trial and Error!!! Guys I hadn't done any casting for over 10 years when I decided to do these Indy car bodies. You wouldn't believe how much I forgot. The first body was the Watson roadster. I thought I might just slush cast few for our group. That was way too much work compared to one pour with an inner mold. I took the slush cast body, cleaned out the inside, put an interior in it, and started all over. Couldn't believe how many little things I knew I did wrong after that first cast! By the time I got to the Lotus body it all came back and it went a lot smoother.

Guys are right about silicone leaking everywhere, but with a sharp Xacto, you can trim your mold to get rid of anything that shouldn't be there. The Alumilite high strength is really great for the inner mold. It is so flexible that it will come out of your body easy and not tear if you stretch or pull it a lot.

Re: Casting

Posted:

Thu Aug 20, 2015 6:30 pmby Gameover

Well mold number one is complete! Yahoo!!!! I did it lol. Now im waiting for my resin release to show up in the mail and ill be casting this bad boy!!!

Re: Casting

Posted:

Thu Aug 20, 2015 6:34 pmby btaylor

Good going Steve! looks like your on your way.

Bob

Re: Casting

Posted:

Thu Aug 20, 2015 6:52 pmby Gameover

Now i just need to find more bodies and get more silicone :).

Re: Casting 1956 ford f100 mold completed

Posted:

Thu Aug 20, 2015 8:14 pmby Alaskaracer

Would you like to try casting my 53 Ford sedan?