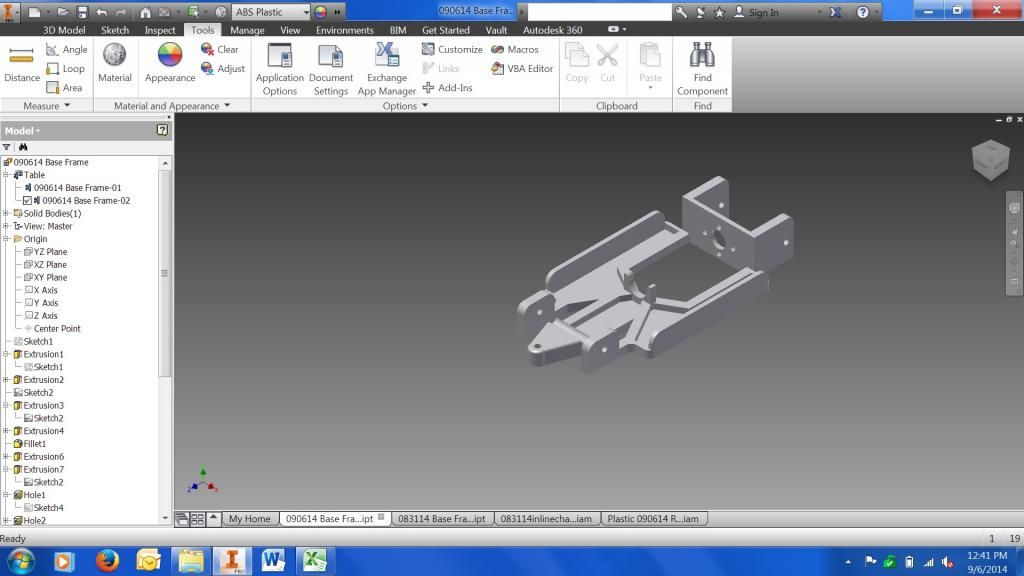

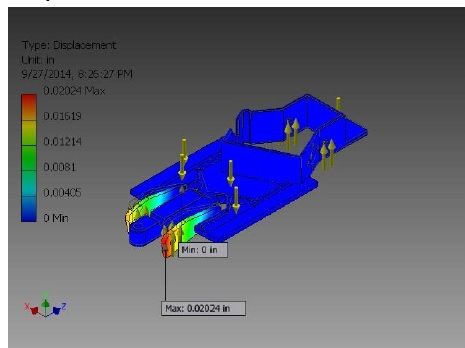

To answer a few, I spend about 2 hours each evening four five days drawing up the model and testing it by stress analysis, then on Saturday morning I spend another three hours redesigning and testing again, then about 1 hour printing out the model on my little Solidoodle 3d printer using .03 mm resolution. Then I take the printed chassis out to what the Grand-kids call 'Man-Wan' and the transformation begins. The tubing is measured, cut, and filed to length from the assembly model, and by evening I am able to play with the chassis on the track.

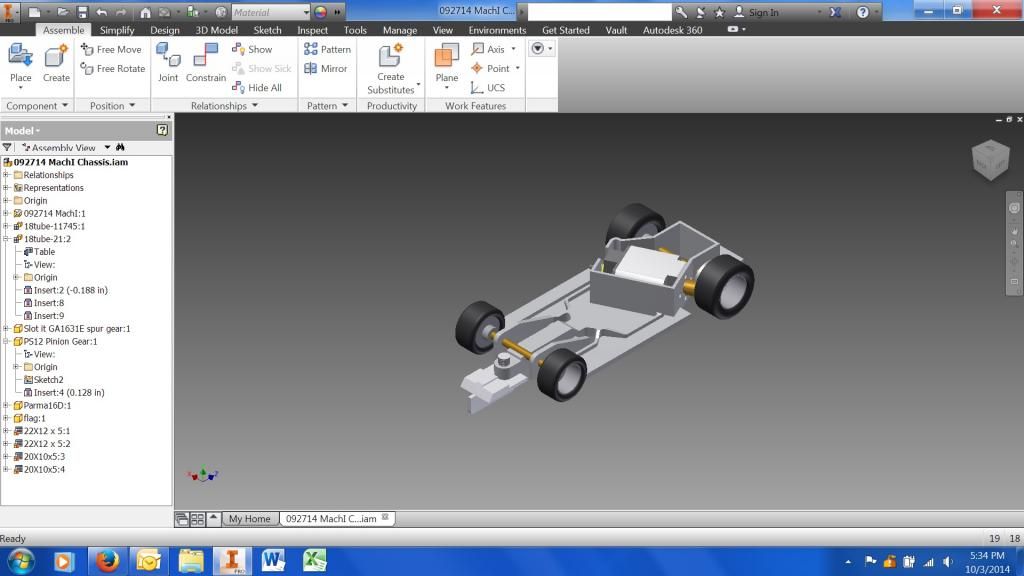

From the Assembly model I can set the front wheels to just skim the track, ensure the proper angle for the slot-it gears, and different tire combinations. At this time I only have the Parma and PM flags modeled up with slot-it wheels and PGT tires. The motors that I have modeled up are the Deathstar, a pair of HR Hawk motors, and an Evil 9 motor.

I've tried two piece chassis where I've had different motor mount positions, (Inline, side-winder, & Angle-winder) and a rear pivot suspensions but due to the printer and some of my abilities, I haven't had much success yet with those. Recently though, thanks to the Florida Slotter, I've had success in making a tuning fork chassis that floats similar to his wire chassis'.

Currently I am in process of making new chassis for the Mach I I got from Choc-ice. Once this one is complete, I plan on taking the car down to the local track in Fresno and see if it performs better than the Brass chassis I tried there that is on another Mustang with a lexan body. More on that later.