Hi all

I have designed an analog scalextric track that has about 72’ of track. I am using the arc air power base, but in doing a little reading it seems I may need some power taps to ensure complete power coverage around the circuit, first of all what are power taps and how many would I need for my track size. A little confused on where these things would go and what they hook up to. Help!! Thanks in advance!

Newbie power tap question

7 posts

• Page 1 of 1

Re: Newbie power tap question

Welcome, think of power taps as extension cords from one part of your layout to another. They supplement the sometimes poor contact that the track connections make. I have a scaley sport analog layout of about 38 feet and have 4 sets plus the terminal feed. Works out to a jumper set for each 15 track connections, works fine for me.

- seal666

- Posts: 95

- Joined: Wed Oct 03, 2012 2:21 pm

- Location: central nj

Re: Newbie power tap question

Thanks for the link Harry. So if you connect or solder the wires to the track pieces, where does the other end of those wires go? I am confused on that.

- mtrcyclu

- Posts: 27

- Joined: Fri Oct 16, 2015 3:51 pm

Re: Newbie power tap question

We just did power taps on a Scaley track. When you flip the track over you will see little tabs on each rail, although they are at different places on each rail. If you gently bend them up, place the wire under the tab and bend the tab back down firmly you will have a good power tap without soldering.

You can solder, it's just that folks sometime melt the track with the iron.

Also make sure you have good connection between sections. Power taps won't help if you have bad gaps between track pieces. We had to run jumpers (short pieces of wire) between several track sections to get good power.

And the other end of the power tap goes to the wires that feed the power based on how your driver stations are wired. Note that this is per lane, you can combine all of the wires for one side of one lane and then connect to the driver station, all the tap wires for the other side of that same lane, etc.

Personally I do it one rail at a time...if I don't then I make a wrong connection.

You can solder, it's just that folks sometime melt the track with the iron.

Also make sure you have good connection between sections. Power taps won't help if you have bad gaps between track pieces. We had to run jumpers (short pieces of wire) between several track sections to get good power.

And the other end of the power tap goes to the wires that feed the power based on how your driver stations are wired. Note that this is per lane, you can combine all of the wires for one side of one lane and then connect to the driver station, all the tap wires for the other side of that same lane, etc.

Personally I do it one rail at a time...if I don't then I make a wrong connection.

-

chappyman66 - HRW SlotCar Veteran!

- Posts: 1173

- Joined: Mon Sep 10, 2012 7:37 pm

- Location: SW of Mpls, MN

Re: Newbie power tap question

For maximum simplicity do one wire at a time to go from a rail on the power base section to the same rail on the section you've chosen for the power tap. Put a car in a lane on the power base section in the direction of travel and use a strip of tape to mark the rail closest to the left front wheel - we'll call this rail A. One end of the power tap wire will connect to this rail from underneath the power base section. Drive or push the car around to the section you're using for the power tap - the rail closest to the car's left front wheel is the A rail, attach the other end of the wire to this rail from underneath the power tap section. The other rail on the same lane will be B, and the second piece of wire starts at B on the power base and goes to B on the power tap section. If you've done this correctly a car will move in the right direction on the power tap section when you press the controller even if it's not connected to the rest of the layout. In fact, this is the best way to test the power taps before putting your layout back together again.

Repeat this for the other lane(s) and you've basically created a second power base to provide full power at another place on the layout. For additional power taps you can add more jumper wires from power tap section to power tap section, since no power will be lost through the wires.

Slothead

Repeat this for the other lane(s) and you've basically created a second power base to provide full power at another place on the layout. For additional power taps you can add more jumper wires from power tap section to power tap section, since no power will be lost through the wires.

Slothead

-

slothead - The Doctor is IN!

- Posts: 1560

- Joined: Sun Mar 17, 2013 7:04 pm

Re: Newbie power tap question

If it was me I would do a quick test to see if any taps are needed. First disconnect the last track section before the power base. Put a car on that section with its rear wheels off the track and punch the controller for that lane. Measure the voltage on the power section and on the last section. Repeat that for each lane, if the voltage drop is more than a half volt you would first need to locate and fix any poor connections. If the voltage drop is still too high add some jumpers, just one set of jumpers half way around the track might be all you need. Adding a lot of jumpers when your track joints are not good is only a partial solution to the voltage drop problem. If you run cars with powerful traction magnets or with powerful motors that will also tend to increase the voltage drop. Any sectional track can develop faulty joints with time, especially if you run cars with big traction magnets because that flexes the track.

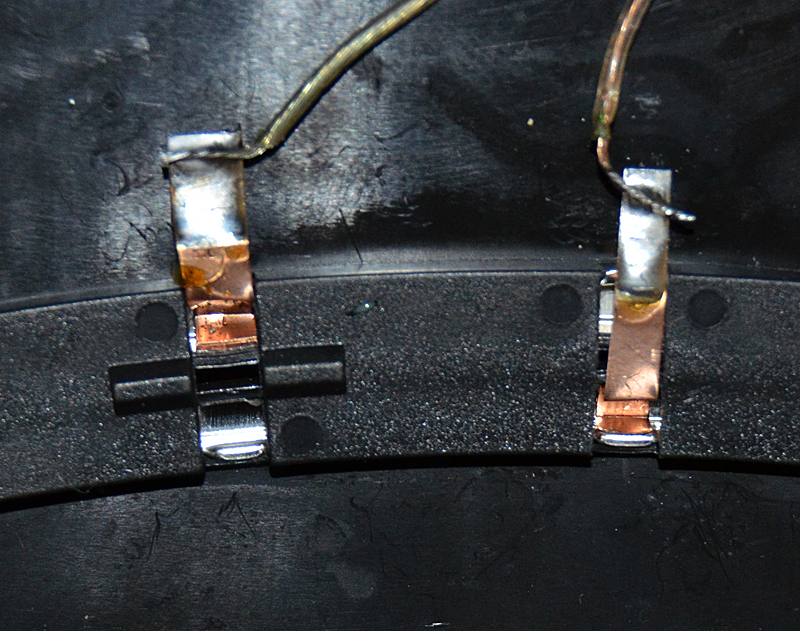

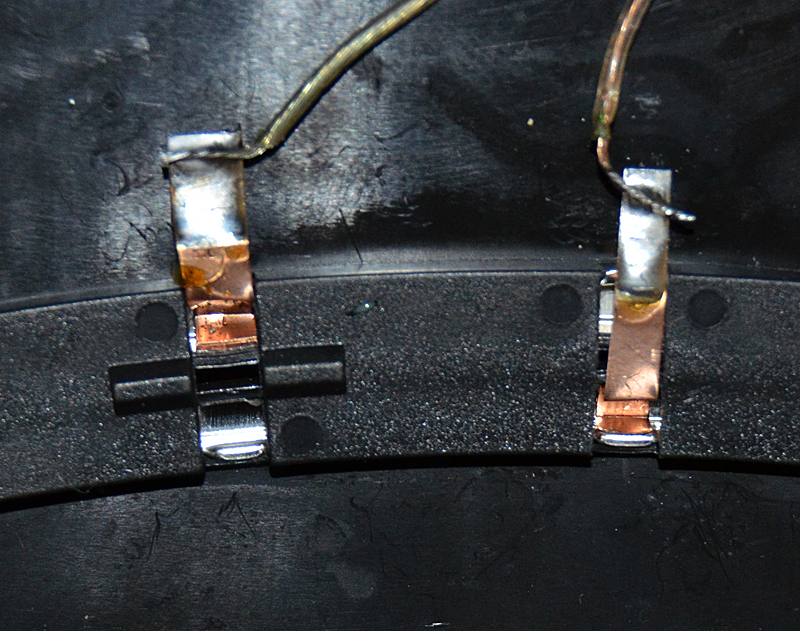

If you do need to add jumpers Scalextric used to sell those. I have made jumpers from phosphor bronze sheet that I got at a hardware store.

These are a press fit and do not have to be soldered to the rails.

If you do need to add jumpers Scalextric used to sell those. I have made jumpers from phosphor bronze sheet that I got at a hardware store.

These are a press fit and do not have to be soldered to the rails.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

7 posts

• Page 1 of 1

Who is online

Users browsing this forum: Google [Bot] and 8 guests