Just a note .if you are running on a wood track why dont you use pro track tires yes they are foam but on my wood track we run them and we use a 40,000 h&r motor on 13.5 volts and the cars hookup great on my oval and for the price of a set of the wheels inserts and tires you use you can save about 25.00 on you build. I build you guys a rtr with a 26.000 h&r motor and pro track tires for about 100.00 plus shipping of 6.00 total 106.00 feel free to contact me on any questions on these 1/32 mods

At tonyslotcar@gmail.com would be happy to help with any questions

slotguy

Complete Northeast Mod build, Origami body and all

43 posts

• Page 3 of 3 • 1, 2, 3

Re: Complete Northeast Mod build, Origami body and all

Hi there,

Im so impressed by this post im going to give it a go myself, modifieds look awesome and my mates are interested in building one each as well so thankyou for the info its very well documented and there is a level if nostalgia with these cars I love. Any tips on folding the laminate and also sticking it neatly together?

Best regards

Tj from Tasmania

Im so impressed by this post im going to give it a go myself, modifieds look awesome and my mates are interested in building one each as well so thankyou for the info its very well documented and there is a level if nostalgia with these cars I love. Any tips on folding the laminate and also sticking it neatly together?

Best regards

Tj from Tasmania

- tjkt46

- Posts: 1

- Joined: Thu Jan 22, 2015 4:41 am

Re: Complete Northeast Mod build, Origami body and all

Tj if you follow the way turbo kev folded his you should have no problems . I fold them the same way when I build a car for someone here at the raceway.if you have any questions on the body or chassis please contact me at tonyslotcar@gmail.com for info I would be pleased to help you can also contact me to order them

Tony

slotguy

Tony

slotguy

- slotguy

- HRW SlotCar Veteran!

- Posts: 134

- Joined: Sun Oct 21, 2012 1:12 pm

Re: Complete Northeast Mod build, Origami body and all

This is the one I have coming. Thanks for offering a different design.

-

HomeRacingWorld - HRW Janitor

- Posts: 15569

- Joined: Wed Aug 08, 2012 2:05 pm

- Location: HRW Skunkworks

Re: Complete Northeast Mod build, Origami body and all

What happened to all the photos on the first page? They were good instructions.....

-

woodman - HRW SlotCar Veteran!

- Posts: 421

- Joined: Tue Feb 04, 2014 4:34 pm

- Location: Kansas City Mo.

Re: Complete Northeast Mod build, Origami body and all

Kevin must have had the photos hosted on his own Flicker page, and as apparently took them out.

Or maybe Flicker has a time limit? I dunno... :think:

Or maybe Flicker has a time limit? I dunno... :think:

-

nhdungeonracer - SCC Mechanic

- Posts: 1776

- Joined: Tue Sep 04, 2012 7:00 am

Re: Complete Northeast Mod build, Origami body and all

HOW TO FOLD NY MODIFIEDS BODIES-

Unfortunately the old links became broken on this thread, and I have been meaning to put up a thread to replace what Kevin had created some time ago. This post is focused more on the actual folding process and not so much on the general car build - but I have had a number of folks ask me about how these bodies go together - so the following is a tutorial set of instructions with photos to show how the Tour Type NY Modified bodies go together...

FLAT LAY -

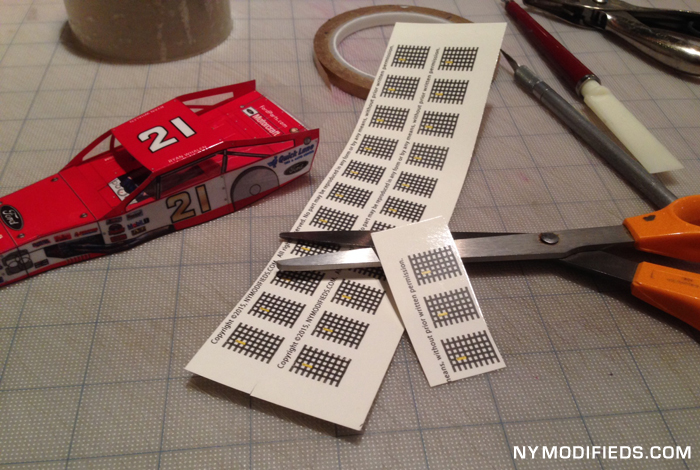

You will need scissors, an Exacto knife, straight edge, some tape - shown laid out here.

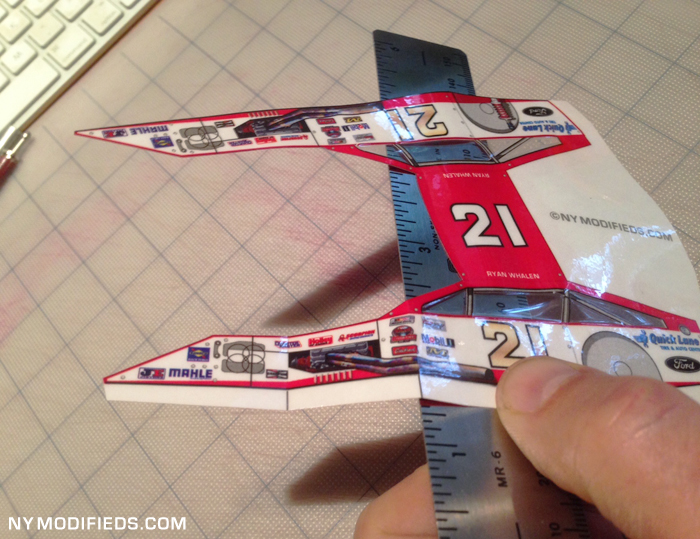

This is how the flat sheets arrive from NY Modifieds - these were selected directly from the online body lists. These particular body sheets are 1/32 scale and they fold up the same way as the 1/24 scale bodies (except the 1/24 bodies probably go together even easier because there's a little more room to work with).

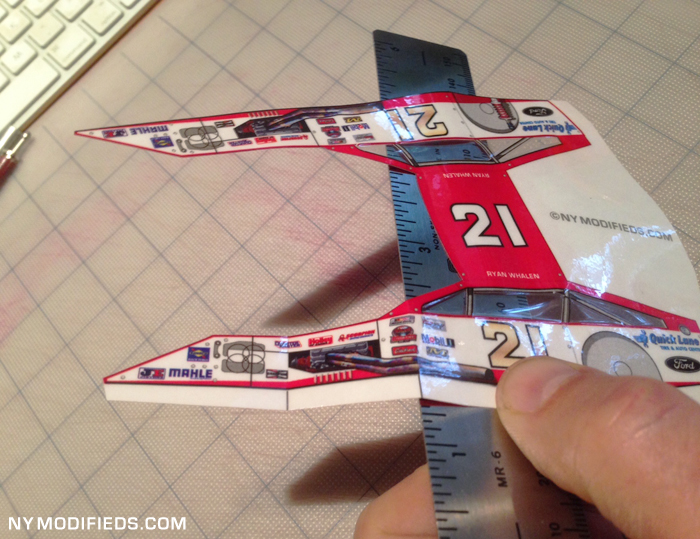

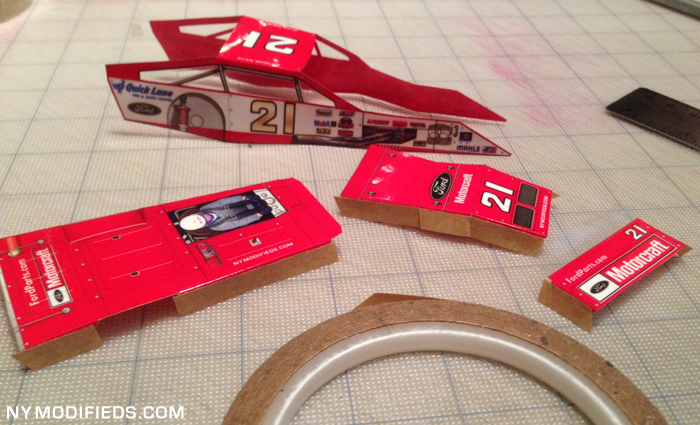

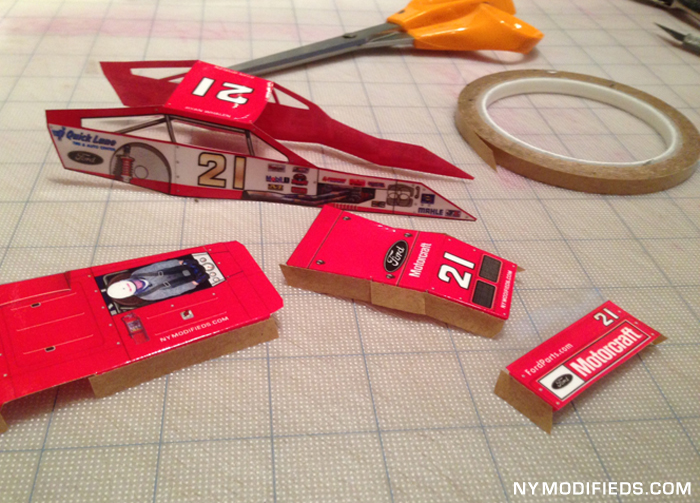

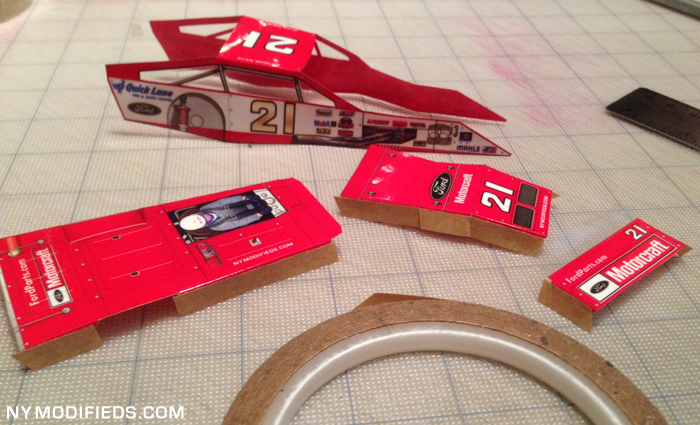

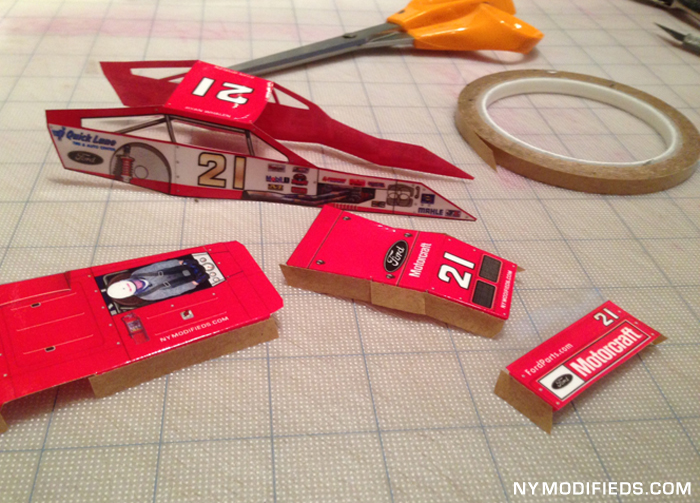

FOUR PIECE MEAL -

Just roughly trim the body parts from the flat sheet. This rough cut should give you four pieces to work with - the body is made up of just these four pieces.

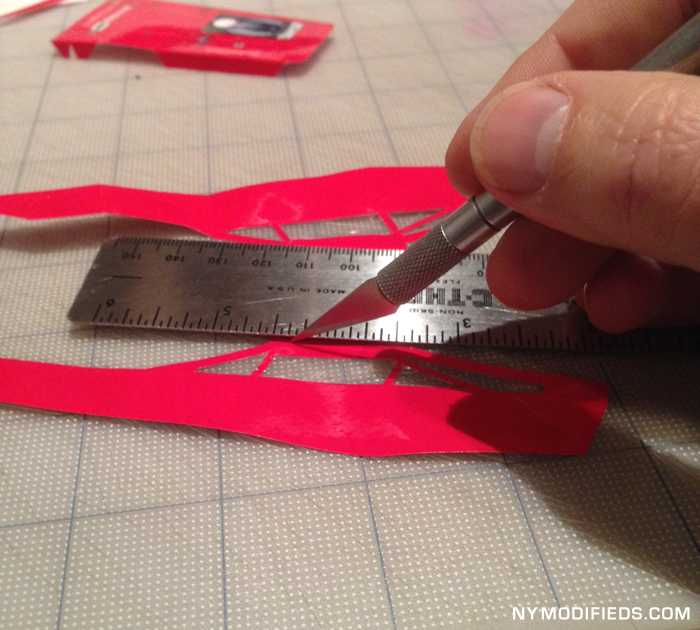

SPOILER ALERT -

Cut carefully around the outline of the four shapes. The rear spoiler has to be trimmed according to the guide lines. This creates a clear spoiler on the back panel of the car - just like the real full size Tour Modifieds!

THE KINKS -

Make a light fold or kink in the left side body work. Just a little pressure along a straight edge - nothing much. This will help the side panel conform to the offset hood and nose shape - just like the big cars.

SHEETS TO THE WIND -

This is what you should have - four pieces of official Modified 'sheet metal' ready to fold and assemble.

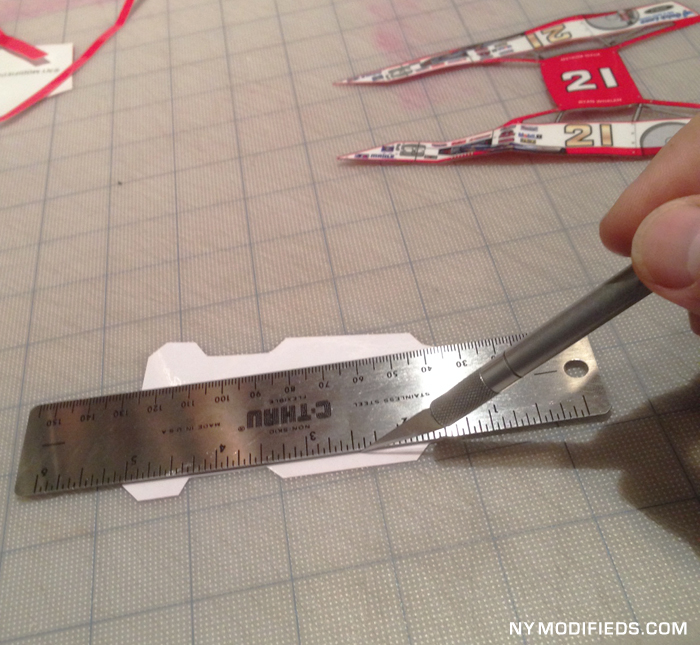

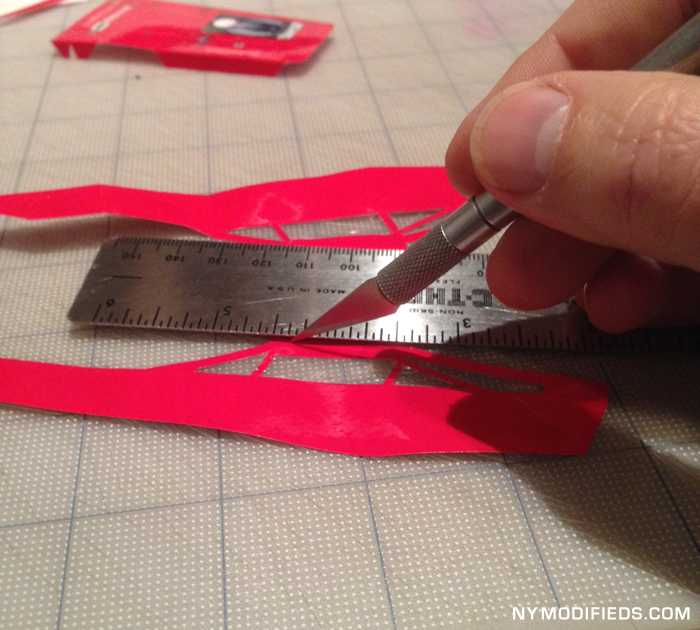

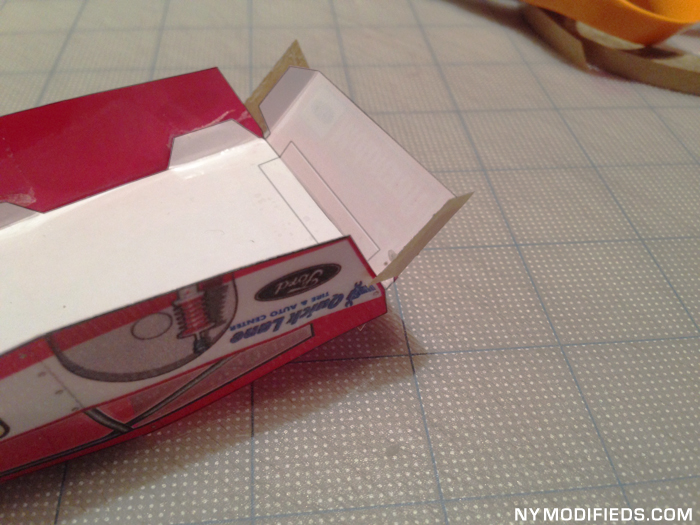

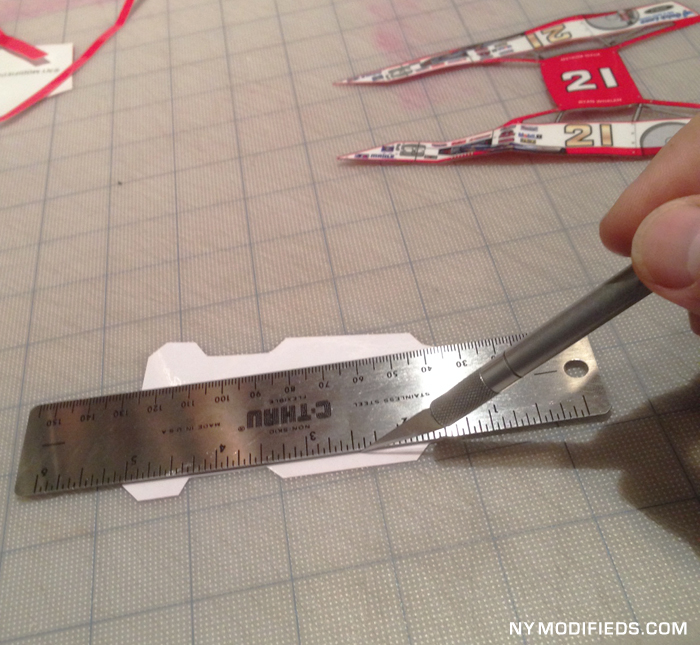

THE BIG TRICK IS THE BIG SCORE -

This is the *big trick* - they key to getting these things to look right and go together easily. Lightly score the backside of the tabs with an exacto/hobby knife. Exert light pressure. Don’t press so hard you cut through the laminate. You just want to score it enough to have a straight fold line.

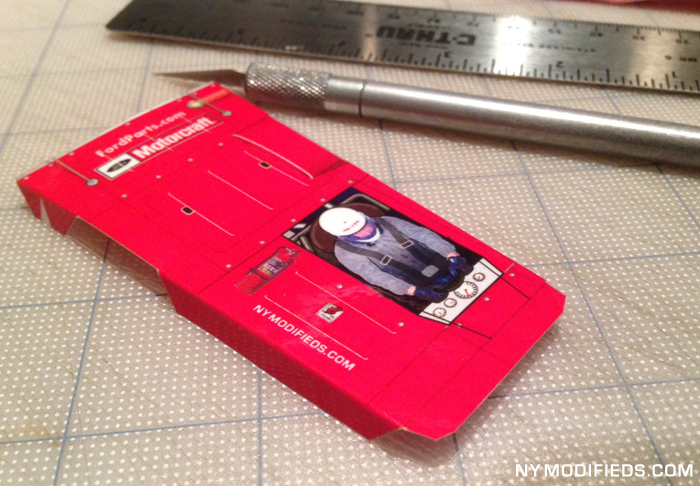

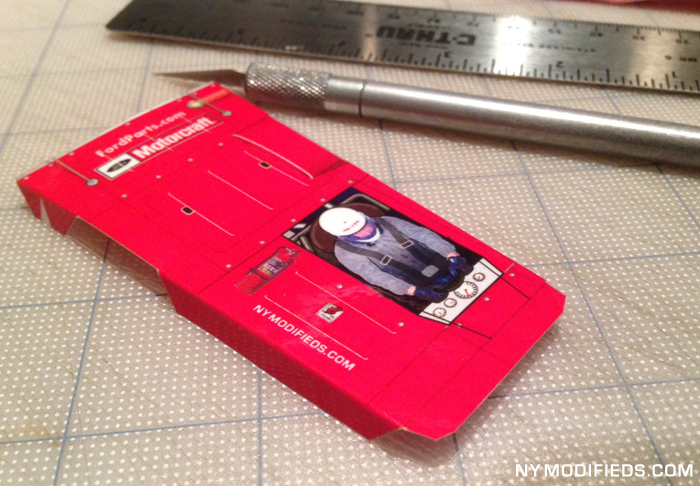

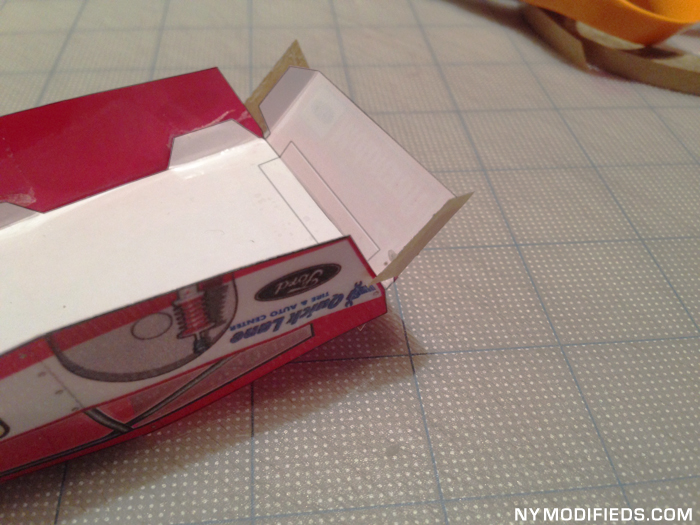

KEEPING TABS -

Fold the tab(s). The tab should fold sharply, straight, and precisely where you made the score. The score on the inside of the bend allows you to fold things exactly where you want them. This is the interior tray with the long tabs folded in position.

ROOFIES -

Again make a slight score, this time along the inside of the roof. A light pressure, scoring on the inside will make for a nice straight fold where you need it - from inside corner to inside corner.

A BODY OF WORK -

Now you should have four folded body panels. There is a slight kink added to the nose with a straight edge. Similar to the left side kink we added earlier. This will allow the nose to conform to the side panel 'wedge' profile shape.

THE BASEMENT TAPES -

This is where folks will differ. Some put these together with staples. It is the fastest and maybe strongest method and it is fine for racing - I mean these are slot cars, not model contest finalists. I myself use double sided tape on the tabs. It allows me to position the panels exactly where I want them, and ultimately it looks cleaner and is more 'scale model appearing' without the staples being visible on the body work.

3M = MINNESOTA MINING MANUFACTURING -

I actually use what is known as an 'adhesive transfer tape' - not strictly a double sided tape (although that would work if it is thin). The 3M brand adhesive transfer tape goes down and then the backing lifts off, leaving only the glue in place. We used this for mechanical art in the years BC (before computer) - back in the days when “cut and paste" was not just a keyboard command.

PLUMB AND SQUARE -

The next step is to start taping the parts together. Actually some guys just use scotch tape over the tabs, and it seems to work fine. For all the talk about staples and special 3M tape, This might be the simplest way of all. Start on the straight side of the body (the right side) first, and at the front section, toward the nose.

INSIDE JOB -

There are guidelines to help you line everything up. Just keep working your way back along the right side. Once the tabs are stuck in the right place, you can add a scotch tape over them to keep them from "walking". Remember things can get rough in the 'bullpen’ when the racing gets serious.

TAB THROUGH -

Once the nose tabs are taped off and assembled - position the interior tray panel flush to the rear corner and at the right height. Then just tape off the tabs.

COME TOGETHER -

Affix the rest of the tabs and the car comes together.

BACK DOOR, MAN -

Use a piece of scotch tape to create a "hinge" for the back panel. Then tuck in the side tabs to make the back panel and spoiler secure.

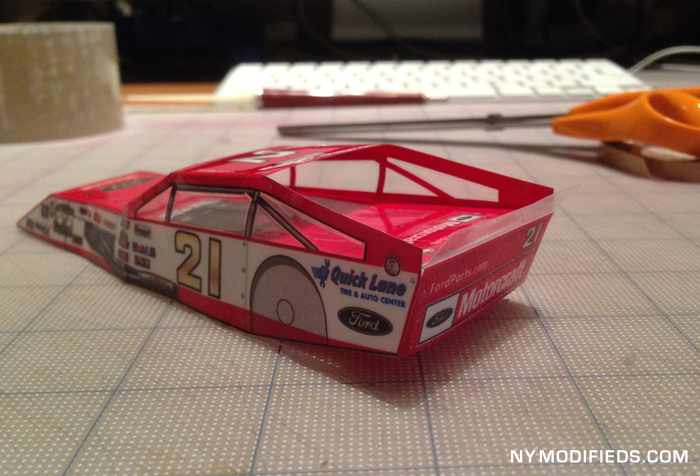

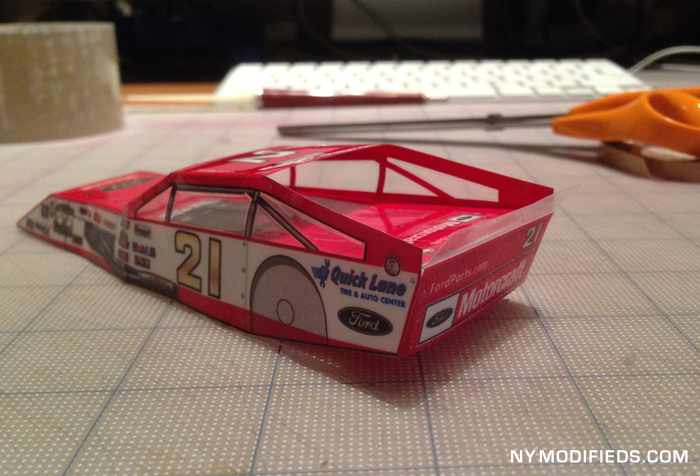

THREE QUARTERS -

This is how it should look. Almost ready to race.

CALL IN THE REINFORCEMENTS -

Although not necessary, it is a good practice if you want to race these hard, to go over the nose with a larger piece of tape (like packing tape). If you are careful it is easy to lay even a large piece and smooth it out so there are no air bubbles. It also tightens up the seams and seals them from the outside without really changing the look of the car.

ON THE EDGE -

You can also just add a standard piece of scotch tape on the edge of the nose.Once you are done you can't even tell there is extra tape there.

TAIL OF THE TAPE -

Same deal - a little tape on the back panel will help keep the body work in shape even when the car gets knocked around a bit.

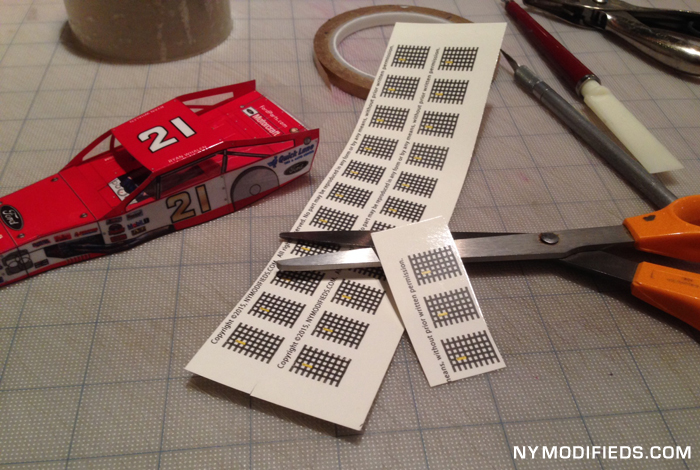

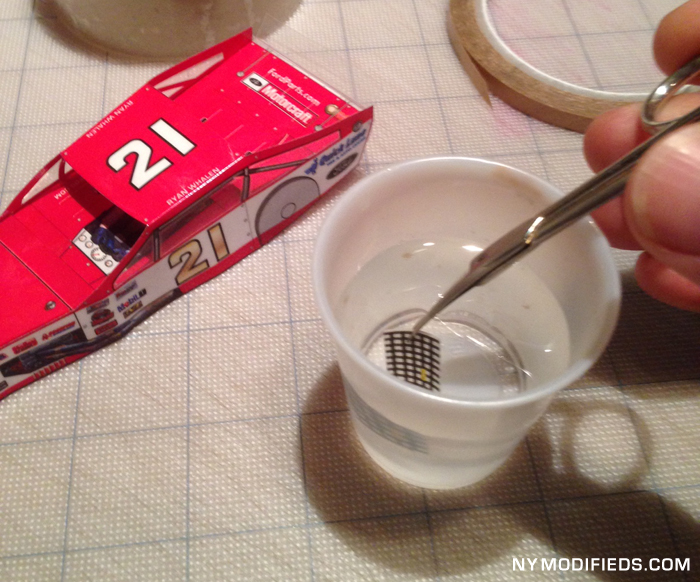

SAFETY FAST -

Trim the driver's window safety net decal very closely.

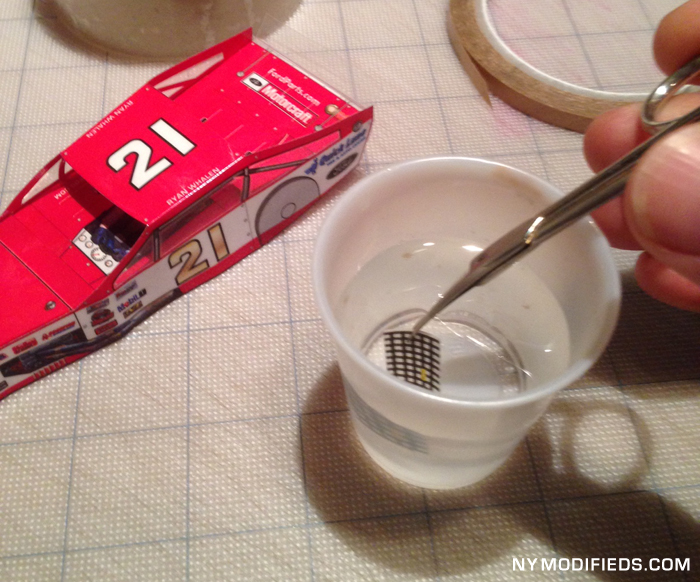

DECALMANIA -

It is a water soluble decal and should start to move on its backing after about 30 seconds in water. You can apply the window net on the inside or the outside of the body. I started doing them on the inside, but lately I did a few with the decal on the outside and it may even look better.

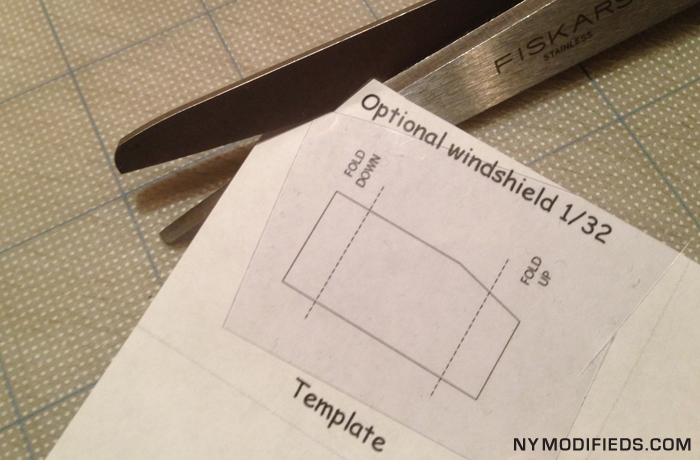

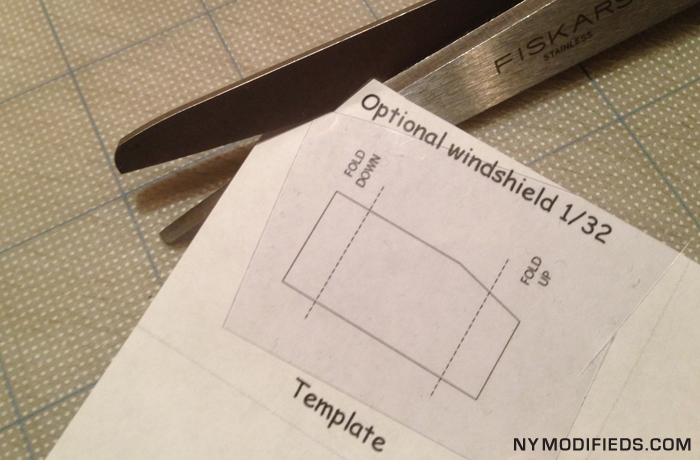

HALF A WINDSHIELD -

Trim the clear acetate type material to the template shape.

Put a small fold on the top and bottom. To tuck under the hood and to the underside of the roof.

Tape the windshield in place.

FINAL ASSEMBLY -

Trim out the rear wheel wells with a small curved scissor.

MAKER'S MARK -

Mark where the front axle will fit the body.

A HOLE -

Punch a hole for the front axle.

FINAL FITTING -

Fit the body to the chassis, then clip in place. Watch out for any interference of binding, trim and relieve if need be, you don’t want anything slowing you down on race day. I have had serious competitors tell me they will spend almost an hour fooling around with the final fit making sure nothing binds and things are loose but not too loose, and the body is positioned 'just so' - but then again these are the guys chasing thousandths of a single second around a giant wooden oval...

In the main though, the body should drop in place rather easily.

Overall, the body should go together in about 20 minutes - although I know they can be done quicker...

Unfortunately the old links became broken on this thread, and I have been meaning to put up a thread to replace what Kevin had created some time ago. This post is focused more on the actual folding process and not so much on the general car build - but I have had a number of folks ask me about how these bodies go together - so the following is a tutorial set of instructions with photos to show how the Tour Type NY Modified bodies go together...

FLAT LAY -

You will need scissors, an Exacto knife, straight edge, some tape - shown laid out here.

This is how the flat sheets arrive from NY Modifieds - these were selected directly from the online body lists. These particular body sheets are 1/32 scale and they fold up the same way as the 1/24 scale bodies (except the 1/24 bodies probably go together even easier because there's a little more room to work with).

FOUR PIECE MEAL -

Just roughly trim the body parts from the flat sheet. This rough cut should give you four pieces to work with - the body is made up of just these four pieces.

SPOILER ALERT -

Cut carefully around the outline of the four shapes. The rear spoiler has to be trimmed according to the guide lines. This creates a clear spoiler on the back panel of the car - just like the real full size Tour Modifieds!

THE KINKS -

Make a light fold or kink in the left side body work. Just a little pressure along a straight edge - nothing much. This will help the side panel conform to the offset hood and nose shape - just like the big cars.

SHEETS TO THE WIND -

This is what you should have - four pieces of official Modified 'sheet metal' ready to fold and assemble.

THE BIG TRICK IS THE BIG SCORE -

This is the *big trick* - they key to getting these things to look right and go together easily. Lightly score the backside of the tabs with an exacto/hobby knife. Exert light pressure. Don’t press so hard you cut through the laminate. You just want to score it enough to have a straight fold line.

KEEPING TABS -

Fold the tab(s). The tab should fold sharply, straight, and precisely where you made the score. The score on the inside of the bend allows you to fold things exactly where you want them. This is the interior tray with the long tabs folded in position.

ROOFIES -

Again make a slight score, this time along the inside of the roof. A light pressure, scoring on the inside will make for a nice straight fold where you need it - from inside corner to inside corner.

A BODY OF WORK -

Now you should have four folded body panels. There is a slight kink added to the nose with a straight edge. Similar to the left side kink we added earlier. This will allow the nose to conform to the side panel 'wedge' profile shape.

THE BASEMENT TAPES -

This is where folks will differ. Some put these together with staples. It is the fastest and maybe strongest method and it is fine for racing - I mean these are slot cars, not model contest finalists. I myself use double sided tape on the tabs. It allows me to position the panels exactly where I want them, and ultimately it looks cleaner and is more 'scale model appearing' without the staples being visible on the body work.

3M = MINNESOTA MINING MANUFACTURING -

I actually use what is known as an 'adhesive transfer tape' - not strictly a double sided tape (although that would work if it is thin). The 3M brand adhesive transfer tape goes down and then the backing lifts off, leaving only the glue in place. We used this for mechanical art in the years BC (before computer) - back in the days when “cut and paste" was not just a keyboard command.

PLUMB AND SQUARE -

The next step is to start taping the parts together. Actually some guys just use scotch tape over the tabs, and it seems to work fine. For all the talk about staples and special 3M tape, This might be the simplest way of all. Start on the straight side of the body (the right side) first, and at the front section, toward the nose.

INSIDE JOB -

There are guidelines to help you line everything up. Just keep working your way back along the right side. Once the tabs are stuck in the right place, you can add a scotch tape over them to keep them from "walking". Remember things can get rough in the 'bullpen’ when the racing gets serious.

TAB THROUGH -

Once the nose tabs are taped off and assembled - position the interior tray panel flush to the rear corner and at the right height. Then just tape off the tabs.

COME TOGETHER -

Affix the rest of the tabs and the car comes together.

BACK DOOR, MAN -

Use a piece of scotch tape to create a "hinge" for the back panel. Then tuck in the side tabs to make the back panel and spoiler secure.

THREE QUARTERS -

This is how it should look. Almost ready to race.

CALL IN THE REINFORCEMENTS -

Although not necessary, it is a good practice if you want to race these hard, to go over the nose with a larger piece of tape (like packing tape). If you are careful it is easy to lay even a large piece and smooth it out so there are no air bubbles. It also tightens up the seams and seals them from the outside without really changing the look of the car.

ON THE EDGE -

You can also just add a standard piece of scotch tape on the edge of the nose.Once you are done you can't even tell there is extra tape there.

TAIL OF THE TAPE -

Same deal - a little tape on the back panel will help keep the body work in shape even when the car gets knocked around a bit.

SAFETY FAST -

Trim the driver's window safety net decal very closely.

DECALMANIA -

It is a water soluble decal and should start to move on its backing after about 30 seconds in water. You can apply the window net on the inside or the outside of the body. I started doing them on the inside, but lately I did a few with the decal on the outside and it may even look better.

HALF A WINDSHIELD -

Trim the clear acetate type material to the template shape.

Put a small fold on the top and bottom. To tuck under the hood and to the underside of the roof.

Tape the windshield in place.

FINAL ASSEMBLY -

Trim out the rear wheel wells with a small curved scissor.

MAKER'S MARK -

Mark where the front axle will fit the body.

A HOLE -

Punch a hole for the front axle.

FINAL FITTING -

Fit the body to the chassis, then clip in place. Watch out for any interference of binding, trim and relieve if need be, you don’t want anything slowing you down on race day. I have had serious competitors tell me they will spend almost an hour fooling around with the final fit making sure nothing binds and things are loose but not too loose, and the body is positioned 'just so' - but then again these are the guys chasing thousandths of a single second around a giant wooden oval...

In the main though, the body should drop in place rather easily.

Overall, the body should go together in about 20 minutes - although I know they can be done quicker...

-

Vintage 1/24 - Mr. NY Modified

- Posts: 505

- Joined: Thu Sep 06, 2012 8:40 am

- Location: Long Island, NY

Re: Complete Northeast Mod build, Origami body and all

Now how about THAT boys?

Well done sir!

Well done sir!

-

HomeRacingWorld - HRW Janitor

- Posts: 15569

- Joined: Wed Aug 08, 2012 2:05 pm

- Location: HRW Skunkworks

Re: Complete Northeast Mod build, Origami body and all

WOW...those are just awesome and the picture tutorials are fantastic!!

-

Broman62 - HRW SlotCar Veteran!

- Posts: 1780

- Joined: Wed Sep 05, 2012 6:29 pm

- Location: NE Ohio

Re: Complete Northeast Mod build, Origami body and all

Wowza!, these are too cool, another beast that is bound to make it here, a trackful of these at speed would be a sight!!

Nice!!

Nice!!

-

FC47 - HRW SlotCar Veteran!

- Posts: 644

- Joined: Sun Jun 25, 2017 7:48 pm

- Location: Berkshire foothills

43 posts

• Page 3 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 10 guests