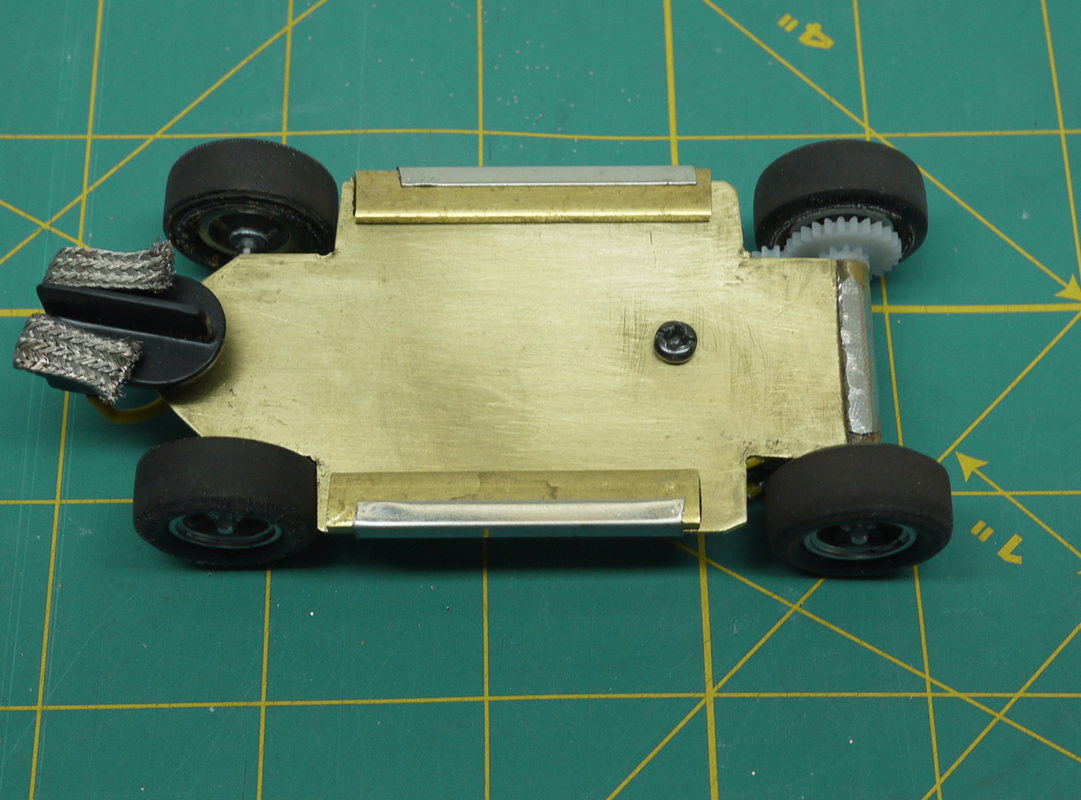

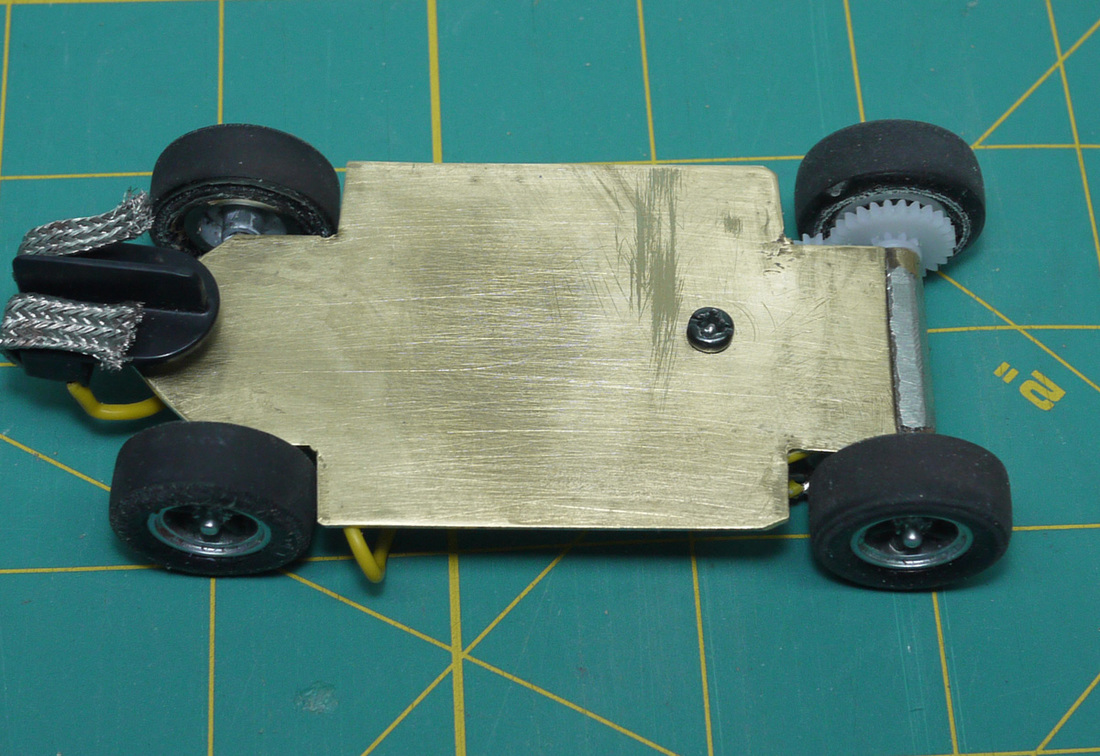

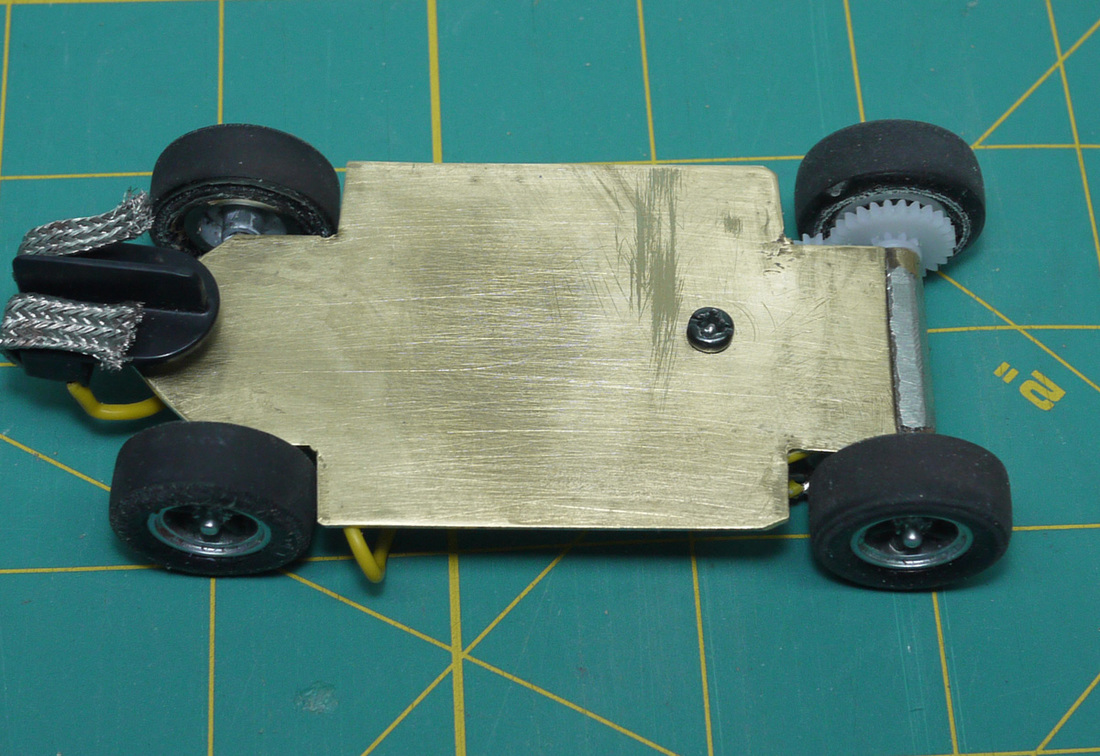

Brass chassis

Well today I built my first brass chassis in over a decade. I want to enter this into the Brass-Am, I have Porsche 911 to put on it,

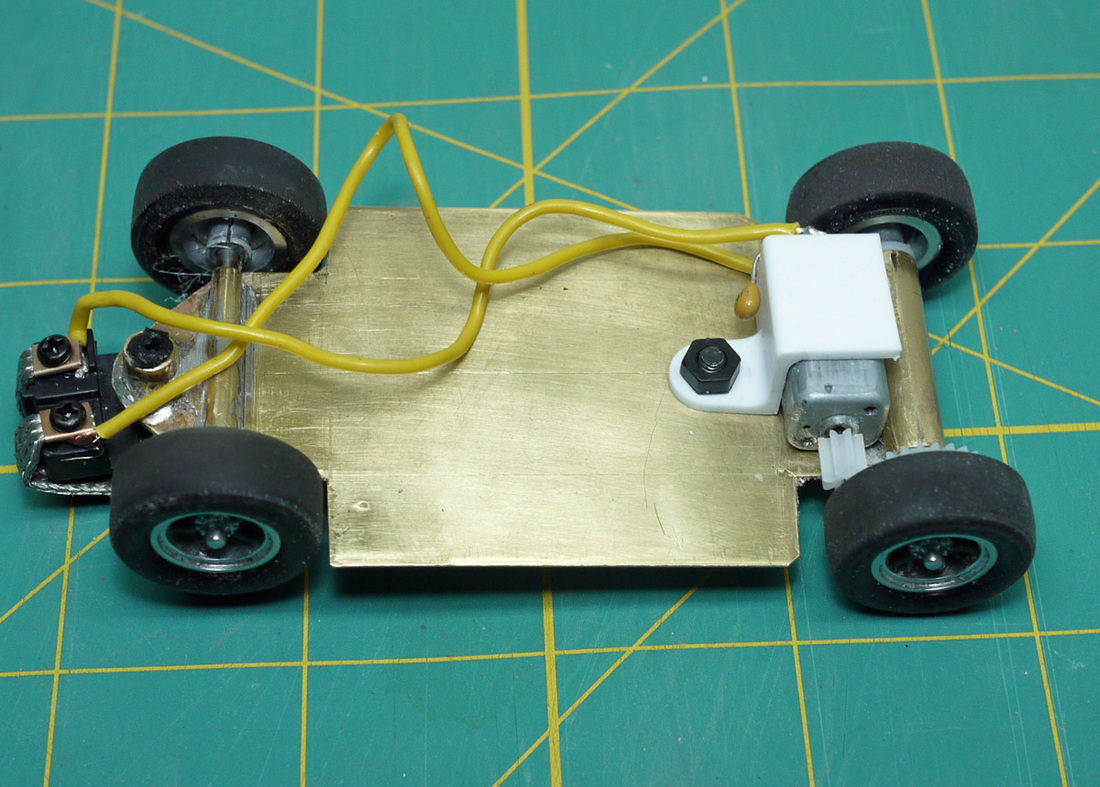

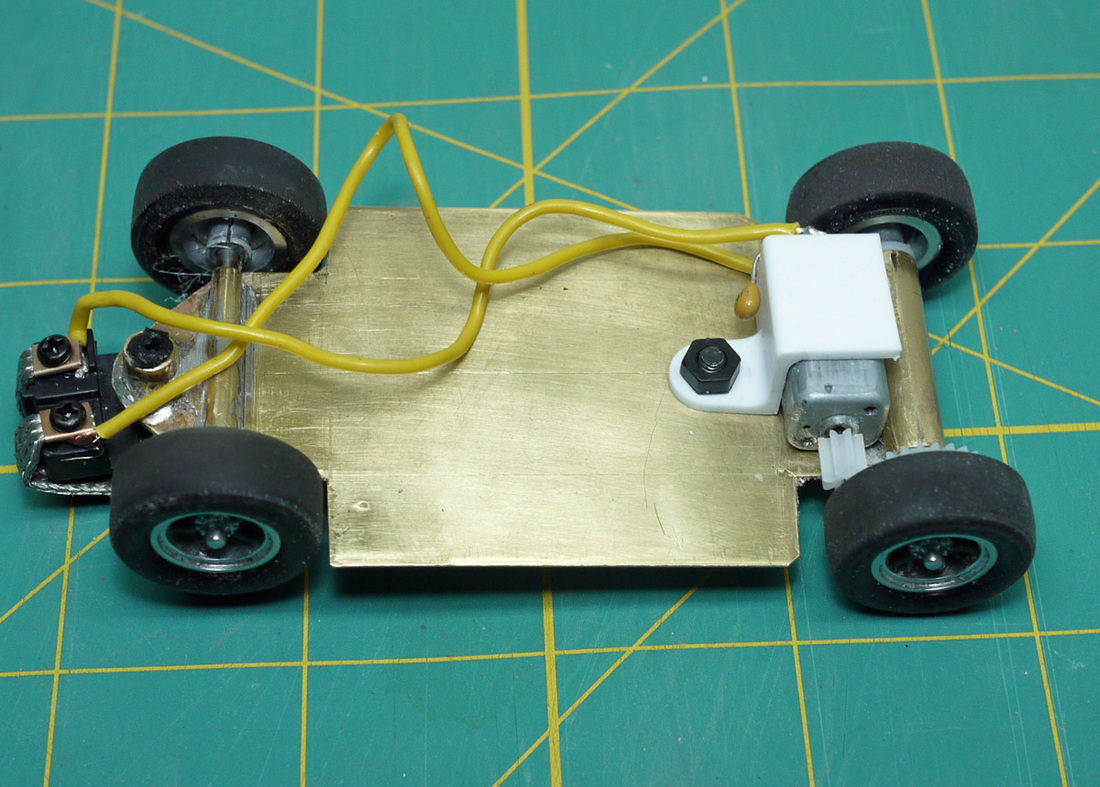

I am using a new S class motor from Minebea. This motor is 10X10 X19mm. I measured the torque today at 48gm/cm, and it is supposed to be turning at 15000RPM @ 12 volts, which feels about right. I will check this when my optical tach gets here. This motor has a 6 pole armature, which I confirmed today when I pulled one apart. It has four permanent magnets in the can. It is supposed ot be a patented design( whatever that is worth today) and the torque is twice that of other similar sized motors. The brakes are really good on this small can motor. From full speed to stop in about 30cm. You can run them for hours and they barely get warm.

I like these motors and have started using themin 143 scale and they knocked a second off my lap times, because of the great brakes. They leave lots of room for detailed interiors which I hope to do for Daves Trans Am proxy.

Pretty simple chassis, not much to go wrong.

So Harry your love of brass is infectious, and I just had to build one to enter in your Brass Am

Cheers

Dan

I am using a new S class motor from Minebea. This motor is 10X10 X19mm. I measured the torque today at 48gm/cm, and it is supposed to be turning at 15000RPM @ 12 volts, which feels about right. I will check this when my optical tach gets here. This motor has a 6 pole armature, which I confirmed today when I pulled one apart. It has four permanent magnets in the can. It is supposed ot be a patented design( whatever that is worth today) and the torque is twice that of other similar sized motors. The brakes are really good on this small can motor. From full speed to stop in about 30cm. You can run them for hours and they barely get warm.

I like these motors and have started using themin 143 scale and they knocked a second off my lap times, because of the great brakes. They leave lots of room for detailed interiors which I hope to do for Daves Trans Am proxy.

Pretty simple chassis, not much to go wrong.

So Harry your love of brass is infectious, and I just had to build one to enter in your Brass Am

Cheers

Dan