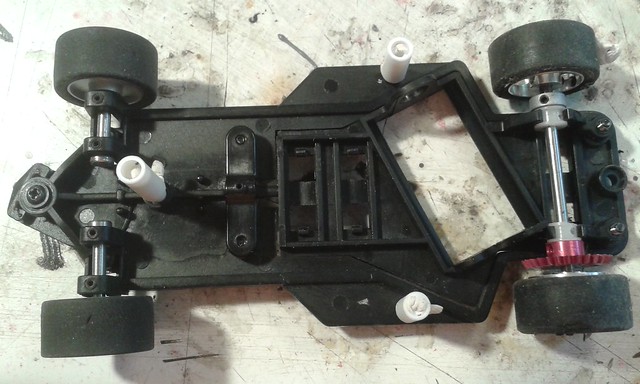

Chassis prior to butchering

Â

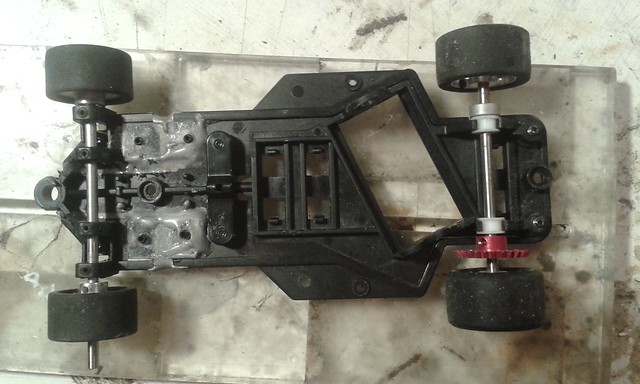

First cut out the front axle uprights

Â

Then put the parts on the jig which has been previously adjusted to the desired size,

making  sure there is a 1mm gap allround to allow for epoxy glue to fill in

Â

Next cut 2 pieces of  transparent lexan sheet 1 mm  thick.I prefer it to other alternatives(brass for example) for 3 reasons

-1mm lexan is stiff and hard

-in many cases rules forbid the use of metall reinforcements to the chassis

-circuit board is thicker and heavier

Â

Â

I superglue them in place then remove the chassis from the jig.Next apply epoxy glue to reinforce the joint,pressing with a wet finger(saliva is best) the glue to fill the gaps around the cutout piecesÂ

making sure they are competely filled

Â

Â

After the epoxy has set I strenghten the joint by screwing 3mm long grub screws

I have used this method to elongateÂ

Â

of shorten wheelbase

Â

Another issue to address on certain cars is that the rear bodypost of the chassis is under the cockpit,preventing us from using a lexan one.Fortunately this chassis has 2 holes on the sides,I drill them with a 2.5 mm bit then countersink them using an 8 mm bit .

Â

Â

An identical  issue is with the front body post,I solved that making a "bridge" of 1mm lexan sheet heated and bemt in the middle,the body of Ninco Mosler

List of the cars I modified so far:

-Ninco Mosler std wheelbase-front bodypost bridge-original rear bodypost used

-Ninco BMW LMR ext wheelbase

-SCX Ferrari 550 Maranello short wheelbase

-SCX Ferrari 599 std wheelbase

-MB Ferrari 430 std wheelbase-front bodypost bridge

-Carrera Ferrari 575 short wheelbase

-SCX Porsche GT1 short wheelbase-original rear bodypost used