Page 1 of 1

Question on the Scaley Indy Racers

Posted:

Tue Apr 10, 2018 7:06 pmby ccobra

I just picked up three ScaIey Indy racers. One of the cars runs around the my track in the low 6 second range where the other two a a full two seconds slower. At first I thought it was the brushes so I replaced the brushes on one and it got worse. Then I replaced the rear tires from the standard Scaley tires. Another item I noticed with the two slower ones is that the front end was jumping out of the slot. So I was thinking my next move would be to add some weight to the nose of the cars but then I noticed something really odd. The Fast one didn't have the centering spring on the flag where the two slower ones had this spring. Could this be the cause of the slot hopping? Or do I need to try the weight thing in the front nose cone? I'm planning on having some high speed drivers (Grandkids) over for memorial day so I must get this right.

Re: Question on the Scaley Indy Racers

Posted:

Tue Apr 10, 2018 8:07 pmby Racie35

Is it easy to remove the spring and try? Is deslotting the only difference mainly in the cars or speed too? 2 seconds is alot

Re: Question on the Scaley Indy Racers

Posted:

Tue Apr 10, 2018 8:29 pmby ccobra

The deslotting is what causes a difference in the speed for the cars can't travel as fast through the technical section of my track due to deslotting.

Re: Question on the Scaley Indy Racers

Posted:

Tue Apr 10, 2018 8:37 pmby HomeRacingWorld

Check the fitment of the tires on the wheels to make sure they are seated.

Re: Question on the Scaley Indy Racers

Posted:

Wed Apr 11, 2018 5:56 amby Ky.Slot Racer

Are you referring to IRL cars, some pictures may help people help you :dance:

Re: Question on the Scaley Indy Racers

Posted:

Wed Apr 11, 2018 8:22 amby RichD

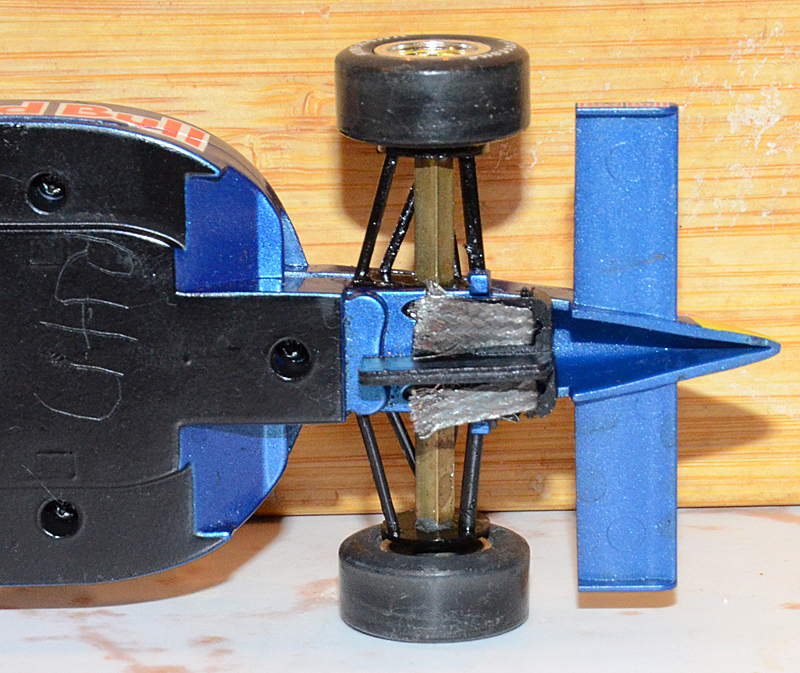

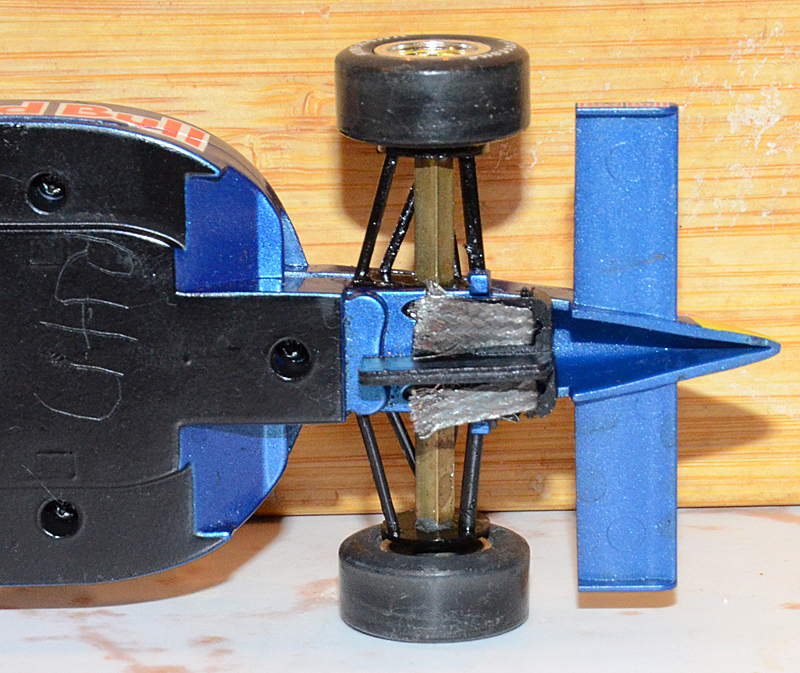

Like this?

These are Dallara IRL cars. My club ran them for a number of years without traction magnets on our wood tracks. It was intended to be a boxstock class with the only modification being a spec pair of slip-on silicone tires. We hoped that this would not be a tuner's class and that the racing would be close. As it turned out there were large differences in performance between the cars, a slower car could get lapped several times during a three minute heat. Finally we spent an evening testing all of the cars. One of our members had a Kelvin Light Bench, that was a sort of dyno stand and was connected to a computer so the data was collected to a spreadsheet. The RPMs for all of the cars were all determined first, next they were run around a skidpad in both directions and the minimum lap time was determined. Finally the cars were run around our most technical track. I still have the data saved from the testing. The motors varied in performance by a fairly significant amount. A particular car might be faster in one direction around the skid pad than the other direction. As you might expect the cars with the best combination of motor and skidpad performance were the fastest on the track.

So now what should we do to equalize the cars? First of all if your motor was a dud you would want to replace it. That left the handling issue. One of our club members is a world class tuner and he figured out a number of tweaks for these cars. If the cars still had their traction magnets the handling differences would probably have been minimized. As it was the front tires did not usually touch the track, having the front tires firmly planted on the track is important when you run without traction magnets. With these cars the guide flag holds up the front, so the braids have to be removed and the bottom of the body of the flag sanded to make it thinner. Normally the braids are looped around the body of the flag so the feelers attached to the chassis can make contact. That makes for a double layer of braid on the bottom of the flag. We glued the braid to the top of the flag to eliminate the doubling. Next it was determined that the front suspension could flex or might be crooked. The fix for that was to drill larger holes through the axle carriers so a piece of tubing could be installed to connect both carriers. With front wheels installed the whole front suspension assembly would be glued in place. That procedure would eliminate the differences in direction seen on the skidpad. The last tweak was to tighten up the rear axle bearings. All of these cars have plastic bearings and the axle is a loose fit. We used the Superglue trick to eliminate the slop. After all of that the cars were more evenly matched.

Re: Question on the Scaley Indy Racers

Posted:

Wed Apr 11, 2018 1:20 pmby Austin

Need to know type of track and if your running with magnets

We know he had a Eldon track but is this the one he is running them on ??

Re: Question on the Scaley Indy Racers

Posted:

Wed Apr 11, 2018 8:43 pmby ccobra

Re: Question on the Scaley Indy Racers

Posted:

Thu Apr 12, 2018 5:57 amby RichD

Since cars with traction magnets run faster if the front wheels don't touch the track the front "suspension" is flimsy. That is why we had to reinforce the front end. Unless your track has Magnabraid traction magnets will be useless because ordinary braid is tinned copper. In my opinion the IRL cars are a little too delicate to be run by kids. Scalextric made some generic "Tupperware" open wheel cars that would be better and they run well "as is" if you turn down the voltage. Once in a while we use them as IROC cars.

Re: Question on the Scaley Indy Racers

Posted:

Thu Apr 12, 2018 7:49 pmby ccobra

Thanks Rich

After noticing your picture of the brushes, I noticed that I didn't do the normal thing I normally do on those which is just having a single lead towards the rear like in your picture. Then after measuring the front height I found there was a 0.040 difference in height which had the faster car lower with both front wheels planted on the track. Looks like I'll have my work cut out for me to get these two slower cars lower. More later after this weekend.