Page 1 of 2

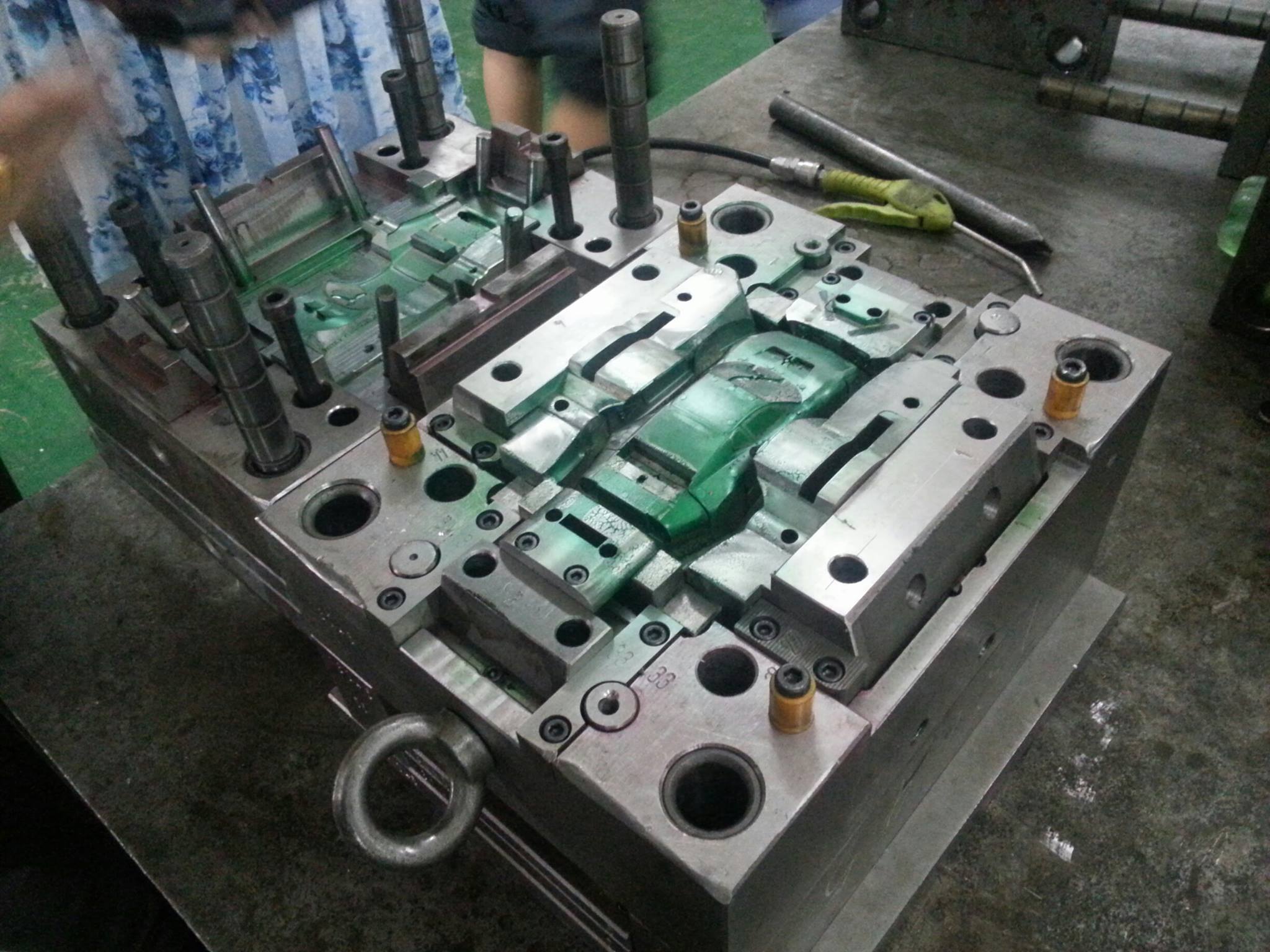

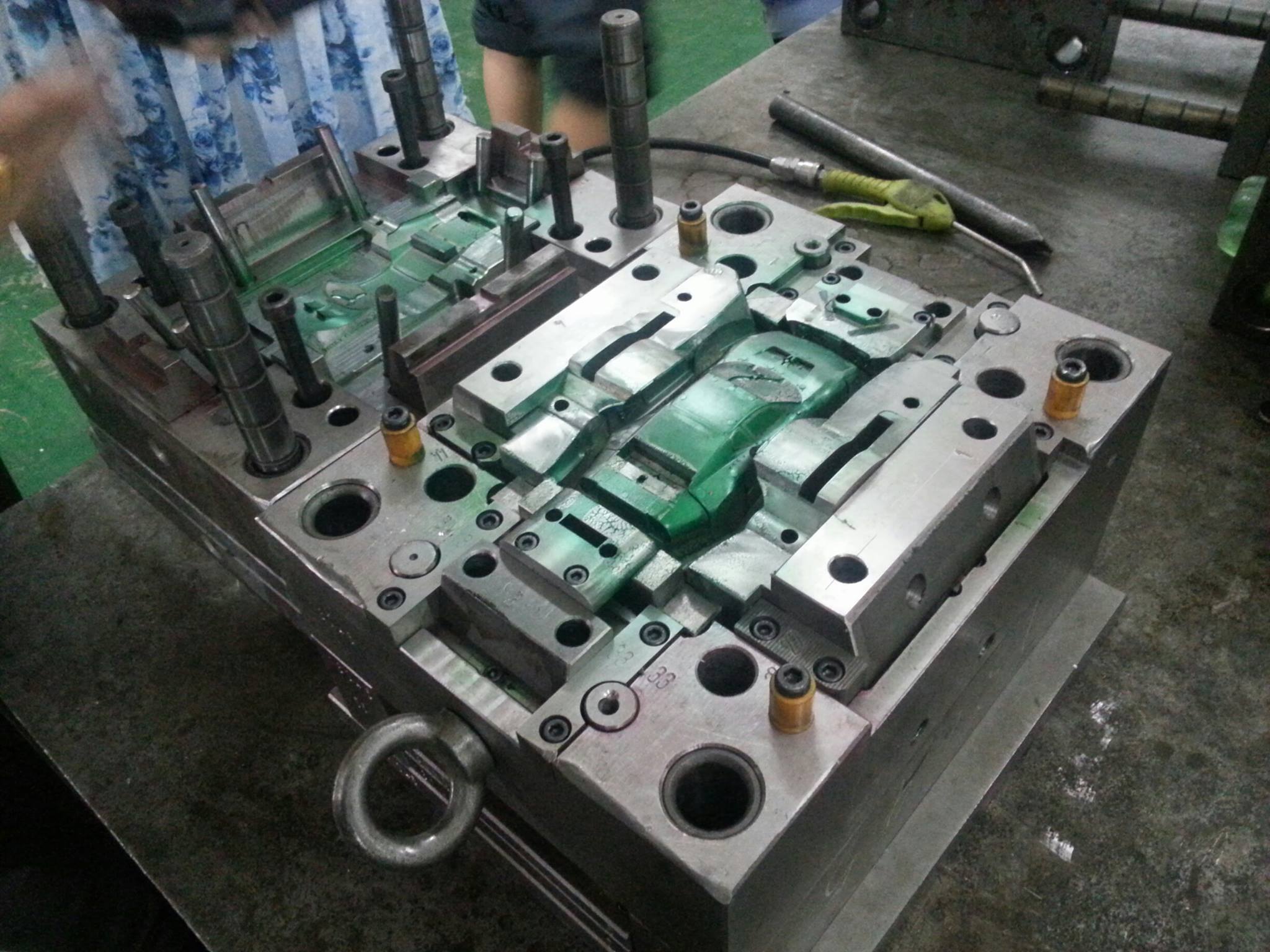

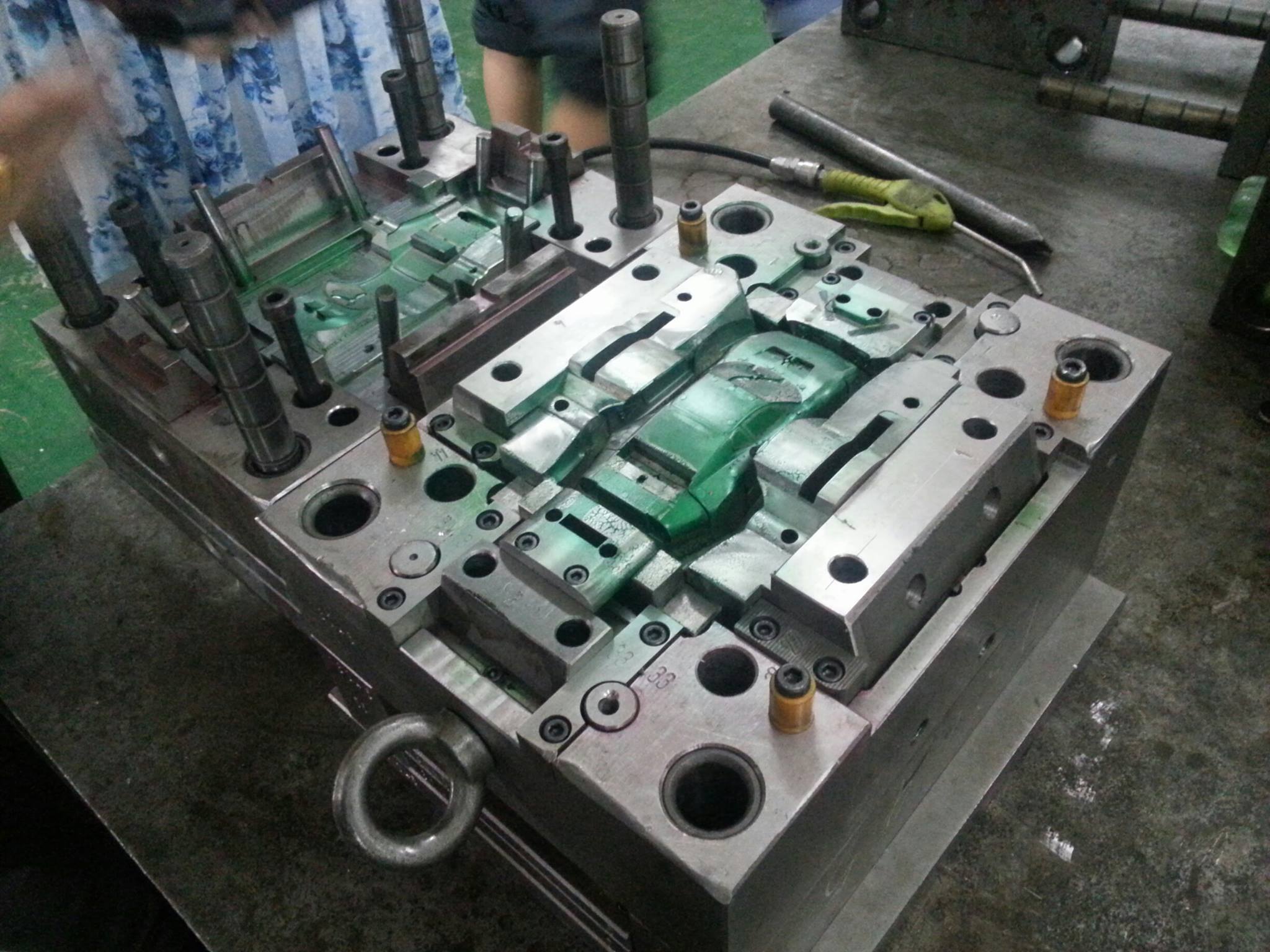

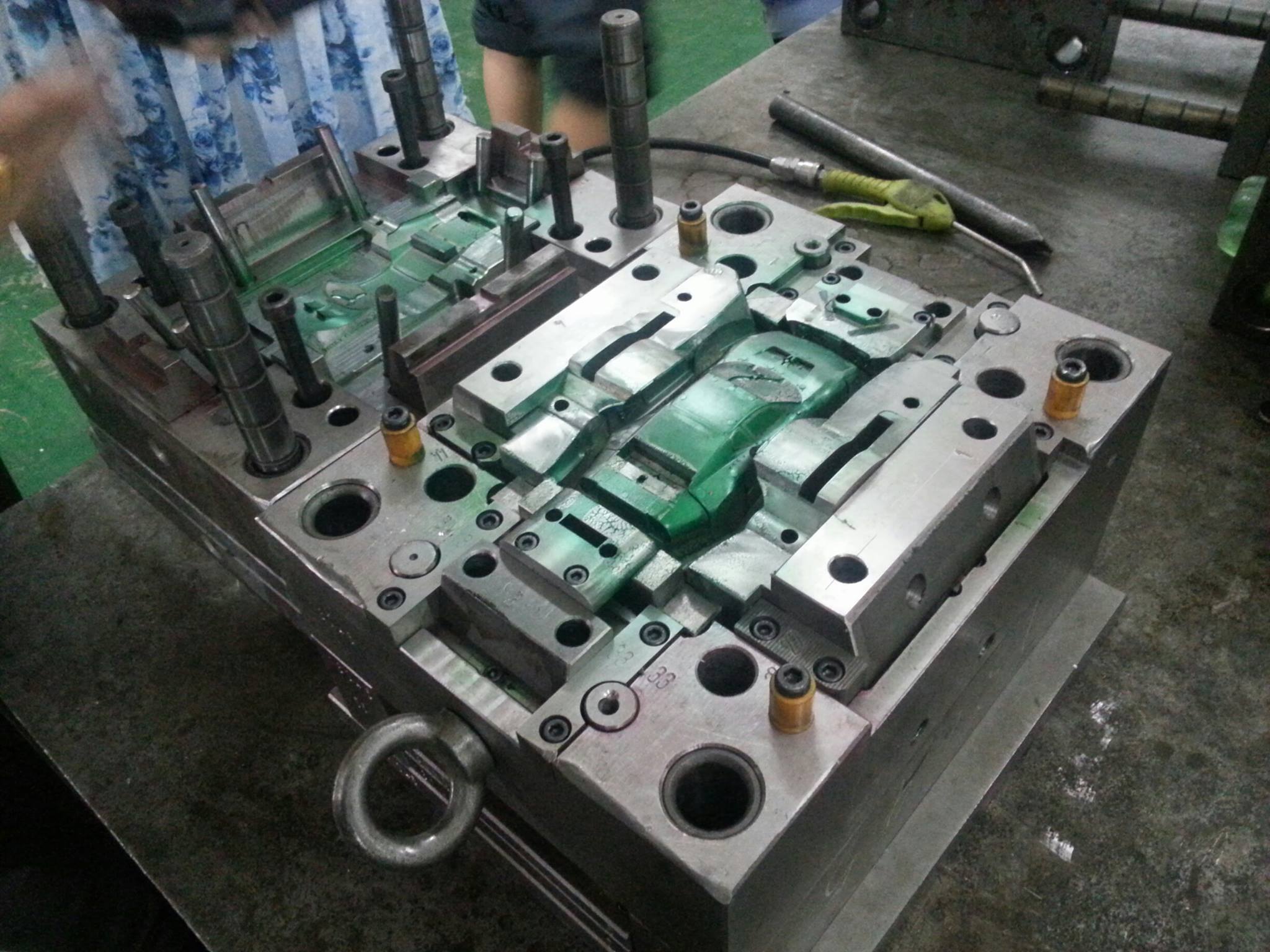

Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 8:28 amby HomeRacingWorld

Seen these and thought some of you would be interested.

Interesting.

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 9:07 amby ListerStormGT

Some big $$$ sitting right there in that. Very cool pics!

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 9:23 amby RazorJon

The 2 sides and both ends slide shut when the press closes, then they open up so the body can be ejected, just think of the fit that it all has to be to not flash we are talking .0005 and less, a hair is .003 :o

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 3:39 pmby DAVE

Looks like it is for the Ferrari BBLM. That tool is for the main body casting. There are lots more

injection molds needed to produce the complete body. And there are other types of tooling

involved in making the many parts that go into a slot car. Not as easy to do as some might think.

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 3:49 pmby waaytoomuchintothis

So, how on earth did they make the hugely detailed plastic models I built in 1958? There's no way they hand-machined molds to a .0005 tolerance, surely.

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 5:00 pmby JULES

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 5:21 pmby HomeRacingWorld

They did with the close to the same...just in black and white :)

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 7:59 pmby waaytoomuchintothis

incredible.

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 8:06 pmby frank9129

Jules,

You will never hear me complain about how long it is taking to turn out the Legends Racers.

You had to make the tooling molds several times.

Frank

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 8:41 pmby Modlerbob

Seeing all this makes one wonder how they sell the stuff as inexpensively as they do.

Re: Racer mold/tooling shots

Posted:

Wed Sep 04, 2013 9:58 pmby chappyman66

The cost is amortized across thousands of shots, so incrementally it's not much (but it is still in there). Yes, the same things were done 60 years ago but they were done by skilled craftsmen....now a CNC and EDM will turn out the mold with far fewer man-hours involved. Very frankly, one of the big problems in this day and age is the loss of knowledge about how to do those things.......but I digress ;)

Also, don't forget that for every body that makes it to the shelves there are several that end up in the scrap/regrind bin for warpage or being somehow out of tolerance......but those shots are still part of the amortization. And often times molds are made to run several different parts at once, with the ability to block off different cavities so that one tool can be used for multiple parts which saves money.

But yes, overall it's still kind of amazing that the body costs as little as it does :D

Re: Racer mold/tooling shots

Posted:

Thu Sep 05, 2013 6:16 amby proxieken

I also wonder how it can be profitable to make the cars. The volume has to be on the low side and the parts and work required are considerable. When you factor in painting and assembling, and then look at what the cars sell to the distributers for it hardly seems possible.

Thanks for the pic of the mold, I have been wondering how the side bits were made. I do plastic injection as a part time hobby but my abilities are very low compared to this. Someday I would like to advance to this level. I was looking at the Palmer Plastics kits and even those are beyond me at this point. Those kits were flat and you had to glue the side of the car to the top, then glue the front and back in. This slide mold sort of does it all in one piece.

It is not clear in the pic where the injection point is. On the cars I have it is impossible to find the injection point, it must cut off so cleanly.

Re: Racer mold/tooling shots

Posted:

Thu Sep 05, 2013 6:52 amby Nor Cal Mike

The guy who produced the HSRR McLarens lives near me and we are occasional slot racing buddies. His primary focus is on producing high end, model trains and railroading paraphernalia. He has injection molding machines in-house and does some production there but also farms some of it out to a company in Viet Nam. He has a CNC milling machine in his shop to produce his own dies and he does all of his CAD drawings to guide the CNC machines and he does the research necessary to produce extremely detailed products. It is amazing how even small seemingly minor parts require multiple die pieces that must be able fold into a closed position and open to release and eject the part. I have watched him and his two employees in operation building parts for an O gauge (I think) truck assemblies for some rolling stock that he sells. It is an amazing thing to see and and a form of art for sure.

Re: Racer mold/tooling shots

Posted:

Thu Sep 05, 2013 1:33 pmby JULES

Re: Racer mold/tooling shots

Posted:

Thu Sep 05, 2013 3:48 pmby DAVE

Gee, with so many "experts" in plastic injection molding, how come I can't seem to

retire without being called back into service almost daily?