New 4 lam pancake armatures

5 posts

• Page 1 of 1

Re: New 4 lam pancake armatures

I haven't been in HO for a while now, in fact, I wish someone would come along and buy all my HO stuff. But I still have some "mean green" arms in the package and some that are out. I'm curious. What is the significance of 4 laminations?

-

waaytoomuchintothis - "Seasoned SlotRacer"

- Posts: 7576

- Joined: Wed Aug 29, 2012 7:16 pm

- Location: Chesterfield, Virginia

Re: New 4 lam pancake armatures

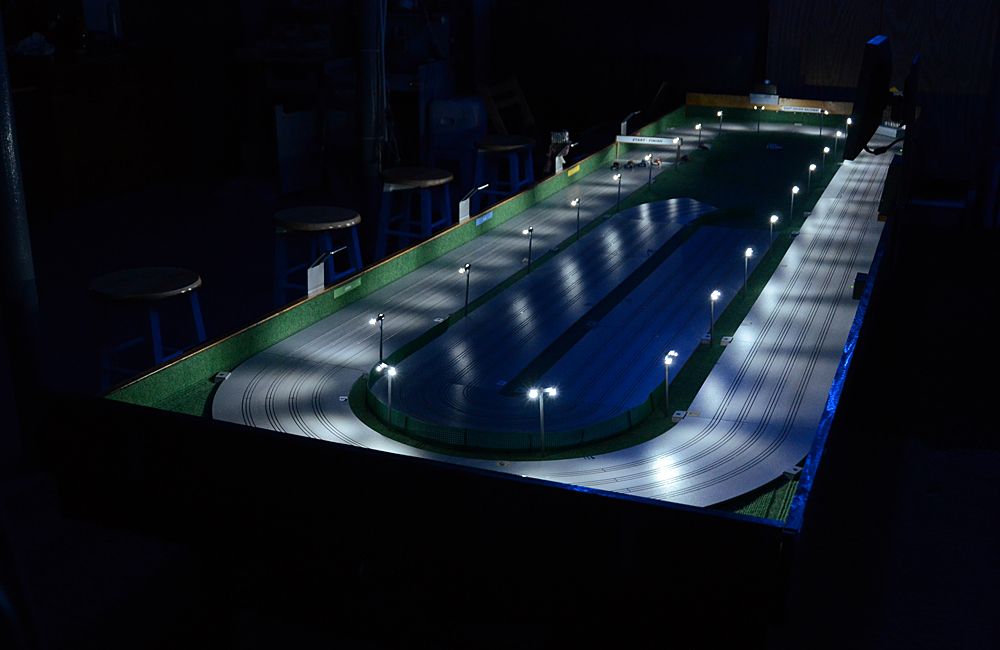

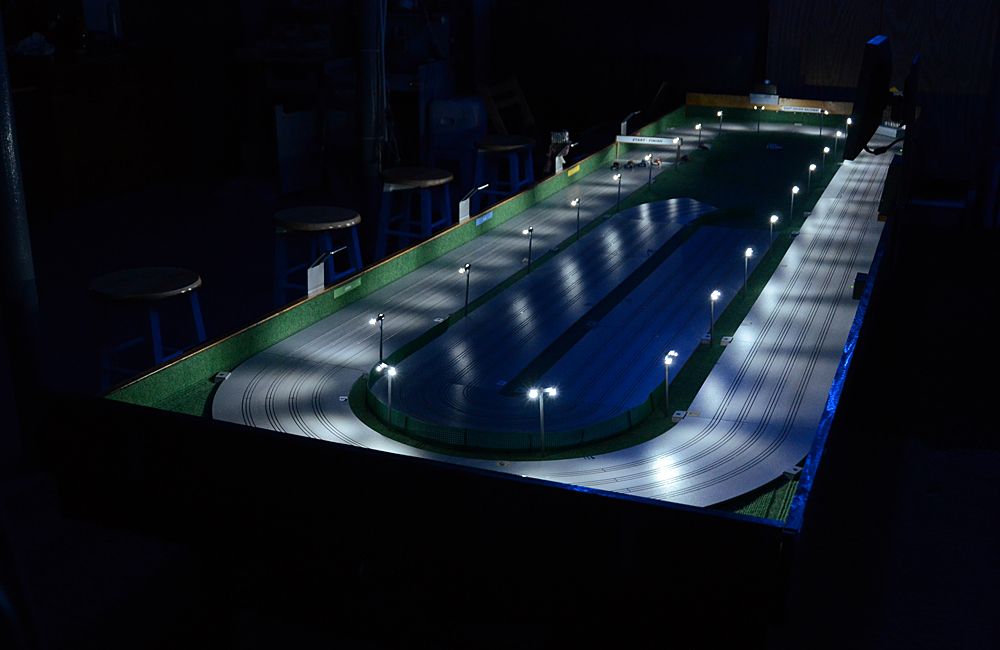

I got five new Dash 4 lamination armatures recently. After I weighed the arms I checked the ohms for each pole and did a quick balance check. All of the arms had decent balance, one was good enough that I would not bother to balance it if I was going to race it. I also checked a mean green that had been balanced, a green lamination with gold wire and a custom wind by Daniel Cardinale on a Johnny Lightning 3 lamination blank. I ran all of the arms in a HOCOC Coupe class car with a T-Jet chassis. The magnets measured 980 gauss. My MaxTrax is in its oval configuration with 12 foot straights and 24 inch radius turns.

I ran the DC arm first because that was already in the car, followed by the mean green, the green/gold and three of the Dash arms. After I put in the first Dash arm I discovered that it was hitting the magnets, so I had to change the magnet shims. The next thing that came up was that there was not enough motor brush tension. I added two thin shims between the arm and the gear plate, I did not use the Teflon spacers that came with the arms. The next thing that I noticed was that the commutator was not flat. After I ran the #1 arm "as is" I trued the comm a little, I did not try to get it perfect, but the lap times did drop. I did the same thing with the second and third Dash arms that I put in the car. After I ran the third arm I changed the phosphor bronze spacers for a thin Teflon spacer and that dropped the lap time a little more. None of the Dash arms wanted to heat up or slow down, they seem to be about equivalent to an average mean green. If I am feeling ambitious I may run the other two Dash arms, my RT-HO tools are getting a good workout.

I ran the DC arm first because that was already in the car, followed by the mean green, the green/gold and three of the Dash arms. After I put in the first Dash arm I discovered that it was hitting the magnets, so I had to change the magnet shims. The next thing that came up was that there was not enough motor brush tension. I added two thin shims between the arm and the gear plate, I did not use the Teflon spacers that came with the arms. The next thing that I noticed was that the commutator was not flat. After I ran the #1 arm "as is" I trued the comm a little, I did not try to get it perfect, but the lap times did drop. I did the same thing with the second and third Dash arms that I put in the car. After I ran the third arm I changed the phosphor bronze spacers for a thin Teflon spacer and that dropped the lap time a little more. None of the Dash arms wanted to heat up or slow down, they seem to be about equivalent to an average mean green. If I am feeling ambitious I may run the other two Dash arms, my RT-HO tools are getting a good workout.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

Re: New 4 lam pancake armatures

Last edited by Ecbill on Sat Nov 21, 2015 8:12 pm, edited 1 time in total.

- Ecbill

- HRW SlotCar Veteran!

- Posts: 167

- Joined: Sat Oct 18, 2014 4:48 pm

Re: New 4 lam pancake armatures

Dash has 2, 3 and 4 lamination armatures, I believe that the laminations are the same thickness for all three types. The more mass the poles have the stronger the magnetic field that they can produce might be. Notice that I said might. These armatures are 4-4.5 ohms, however there are different ways of getting the same ohm value. The wire gauge and the length of wire per pole both determine the final ohm value. You could use a longer length of lower gauge (thicker) wire or a shorter length of higher gauge (thinner) wire to get the same ohm value. Theory says that if there are more turns of wire the arm should put out more power, the length for the lower gauge wire would be longer, so there would be more turns.

While I was fooling around with these armatures I also did some testing to see how much power would be needed to run a car using them. I hooked the car to a bench power supply and measured 0.4 amps at 12 volts. My track power supplies are good for 20 amps, there are two of them with each one running two lanes. The power supplies have digital amp meters and I pointed a camera at one of those while I ran the car around the track. The amperage varied from 0.2 to 0.7 amps. When the car took off from a dead stop the amperage jumped up to 1.2. The track voltage was set at 18.5. A regular set type power supply is good for a bit less than 1 amp. Even if your track had one power supply per lane it would not have enough to get the best performance from armatures like these. For road courses and ovals I would recommend a minimum of 2 amps per lane, for drag racing I would recommend a minimum of 6 amps per lane if you run at 24 volts.

While I was fooling around with these armatures I also did some testing to see how much power would be needed to run a car using them. I hooked the car to a bench power supply and measured 0.4 amps at 12 volts. My track power supplies are good for 20 amps, there are two of them with each one running two lanes. The power supplies have digital amp meters and I pointed a camera at one of those while I ran the car around the track. The amperage varied from 0.2 to 0.7 amps. When the car took off from a dead stop the amperage jumped up to 1.2. The track voltage was set at 18.5. A regular set type power supply is good for a bit less than 1 amp. Even if your track had one power supply per lane it would not have enough to get the best performance from armatures like these. For road courses and ovals I would recommend a minimum of 2 amps per lane, for drag racing I would recommend a minimum of 6 amps per lane if you run at 24 volts.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

Re: New 4 lam pancake armatures

Very interesting stuff. A lot has happened since I was doing HO.

-

waaytoomuchintothis - "Seasoned SlotRacer"

- Posts: 7576

- Joined: Wed Aug 29, 2012 7:16 pm

- Location: Chesterfield, Virginia

5 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 6 guests