It's about 45' per lane, and has power feeds to three spots. My Pyramid power supply has plenty of current available and I always run at 12 volts.

At any rate, for the last few years I've been noticing that when cars are on the outside lane they seem a bit slower than on the inside lane. And the hotter the motor in the car, the more noticeable it is.

Last year I did partially disassemble the track (not easy, it's screwed-down in several places) and checked the connections. There was no corrosion or tarnish, and they didn't feel loose. So I cleaned them a bit (with alcohol) and crimped the ends to make sure there was a good tight connection when put back together. That helped, but not all that much.

Over time I also noticed that on the outside lane there were certain sections where the car didn't accelerate as quickly.

So I finally put a 1 amp load on the track, got out my volt meter and started measuring the voltage drop across track joints. Sure enough, there were significant differences.

A good joint would have 50mv - 75mv. Most had around 150mv. But on the outside lane in particular, there were lots of joints from 250mv to 350mv.

I pondered various options and finally came up with one that I think will work. There is enough room to drill and tap a hole in the plastic underneath the rails. And a 3/32 section of K&S square brass tubing fits inside the rails pretty well, and can be nicely tightened:

I'm going to try this on a small section and hopefully it will solve the problem. I'll post results (but it's hard to say when I'll get the time to work on it).

Have any of you tried anything like this? If yes, how has it held-up over time?

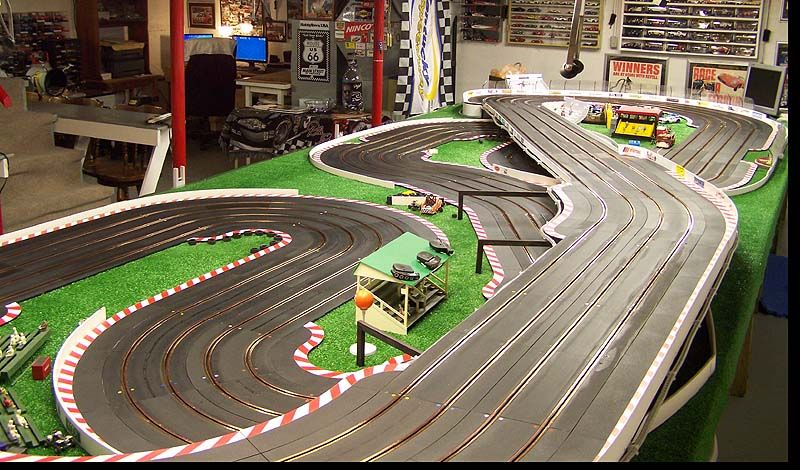

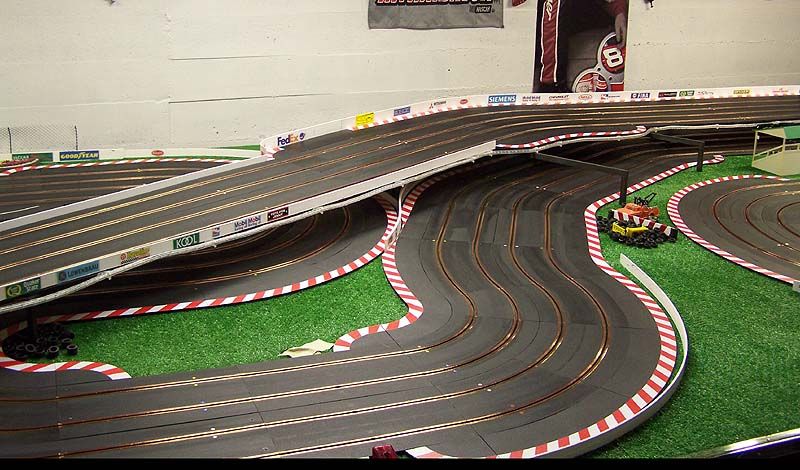

FYI, here's my layout:

Ron

PS, I'm looking for other casual racers in the north-west burbs of Chicago.