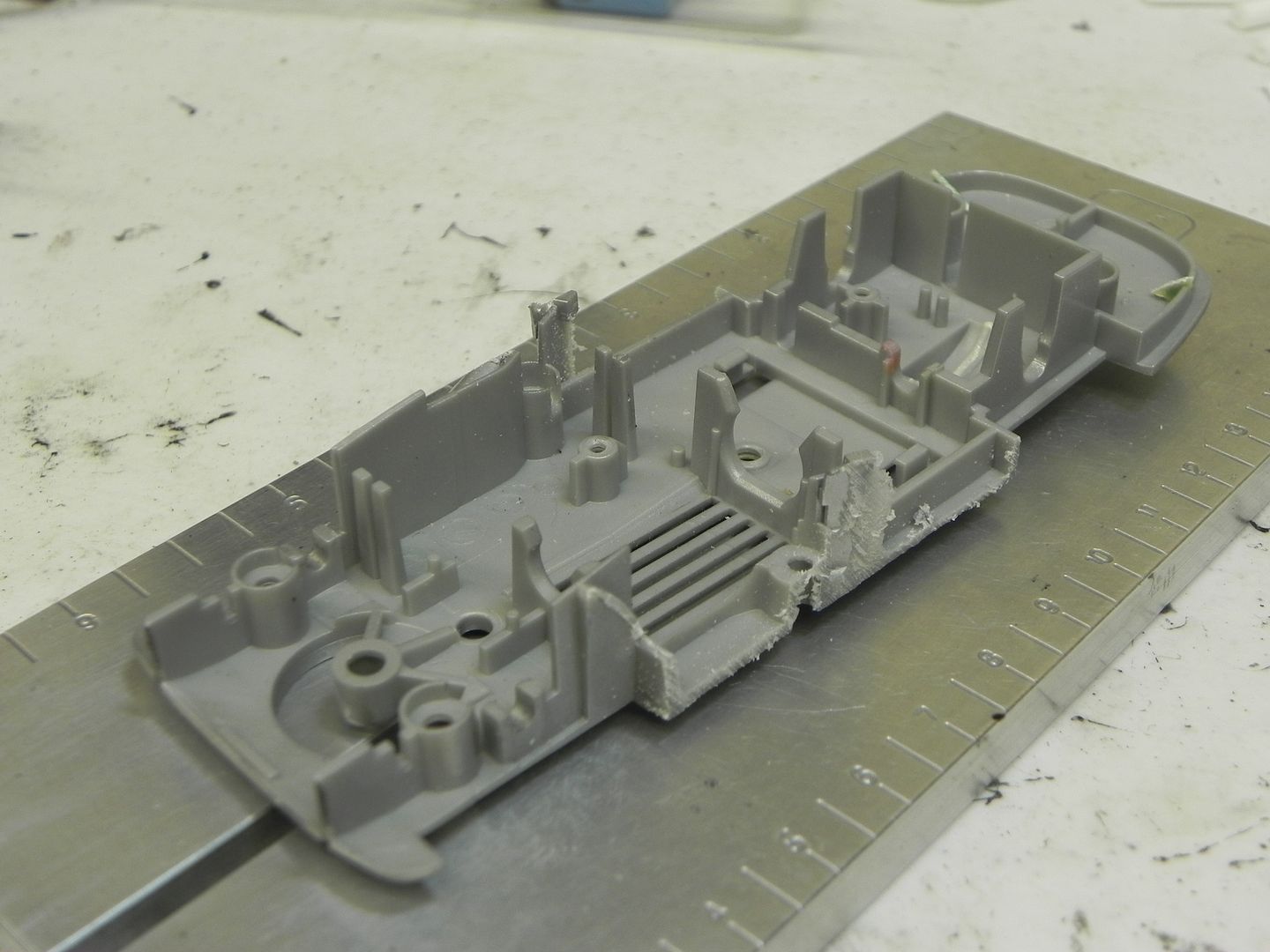

As with several of the Scaley cars in the classic line, this one has the rocker panels attached to the chassis, instead of on body. Since I was concerned about being able to get reasonable body float with this structure, I decided to migrate them off the chassis and onto the body. Here's a picture of the chassis with the rockers cut off:

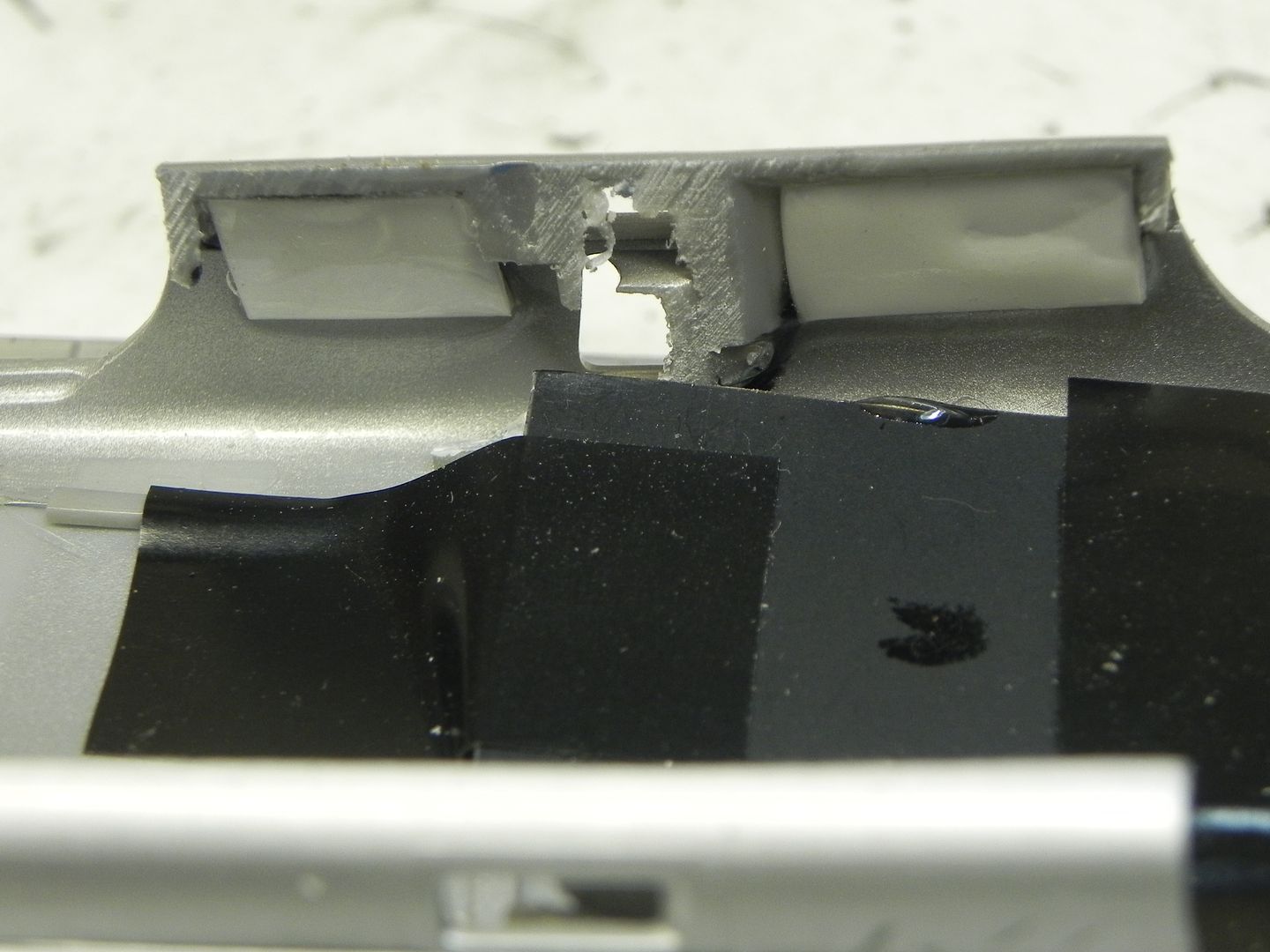

I screwed the body back onto the cut chassis and tack-glued the rockers on with thin CA, using tape to hold the rockers in place against the chassis. Then I backed the CA with my favorite plastic-to-anything glue (Loctite 389 - thank you, Chris Walker (chrisguyw)!). Then I mixed up some 30 minute epoxy and used that in conjunction with 1.0mm plastic strips, to strengthen the rocker joints:

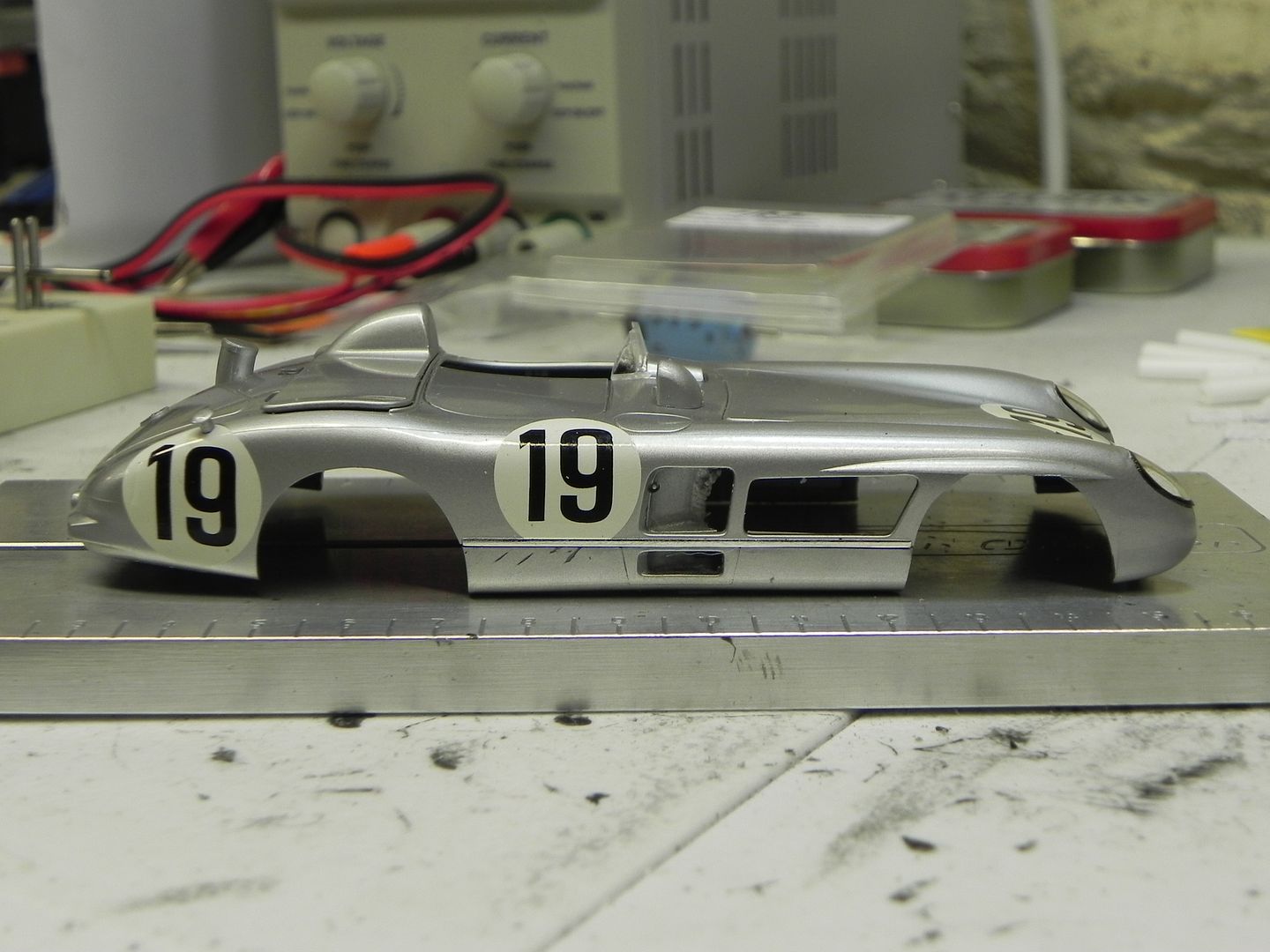

After setting up for 24 hours, the result was pretty strong and the look was OK:

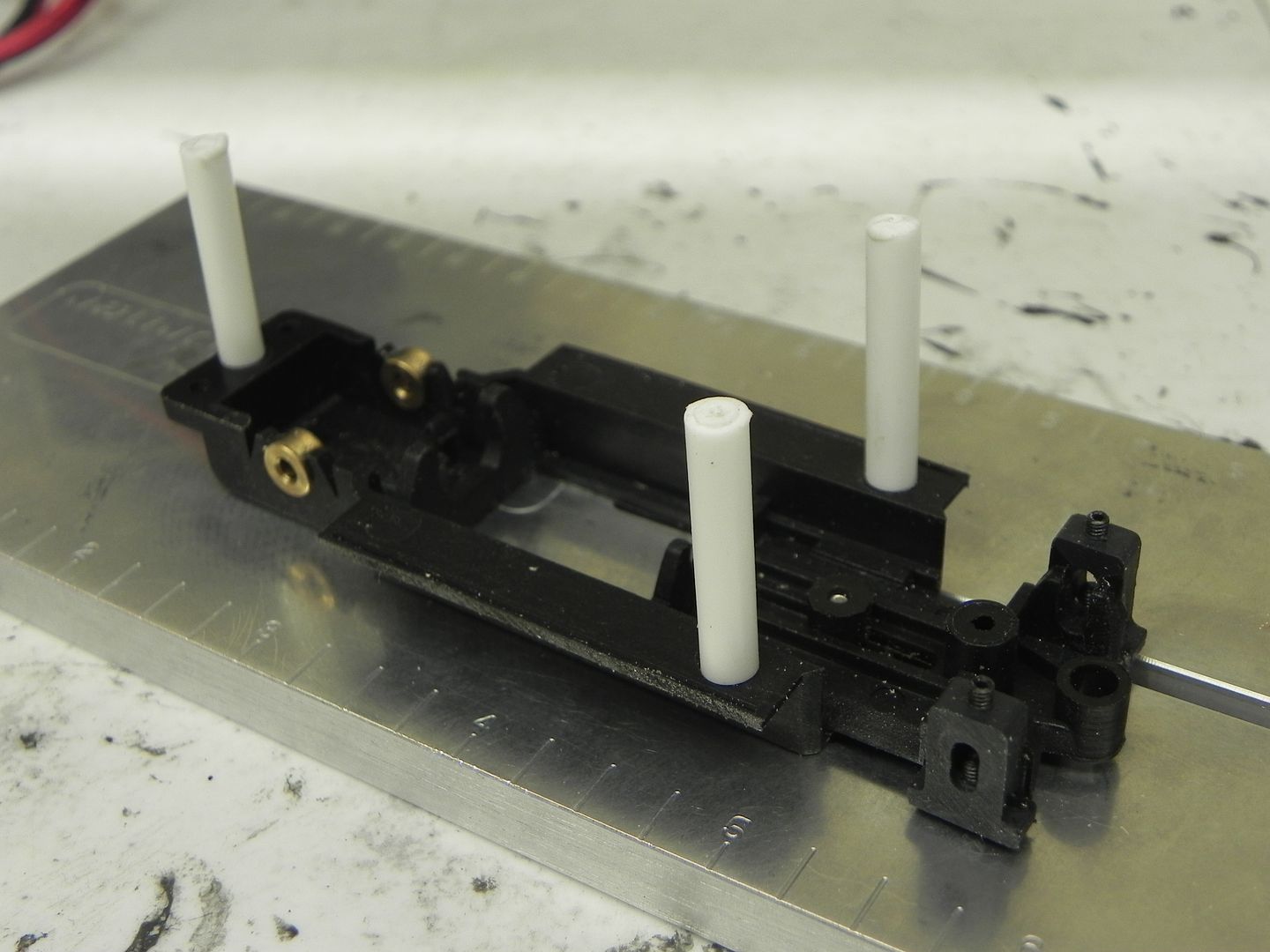

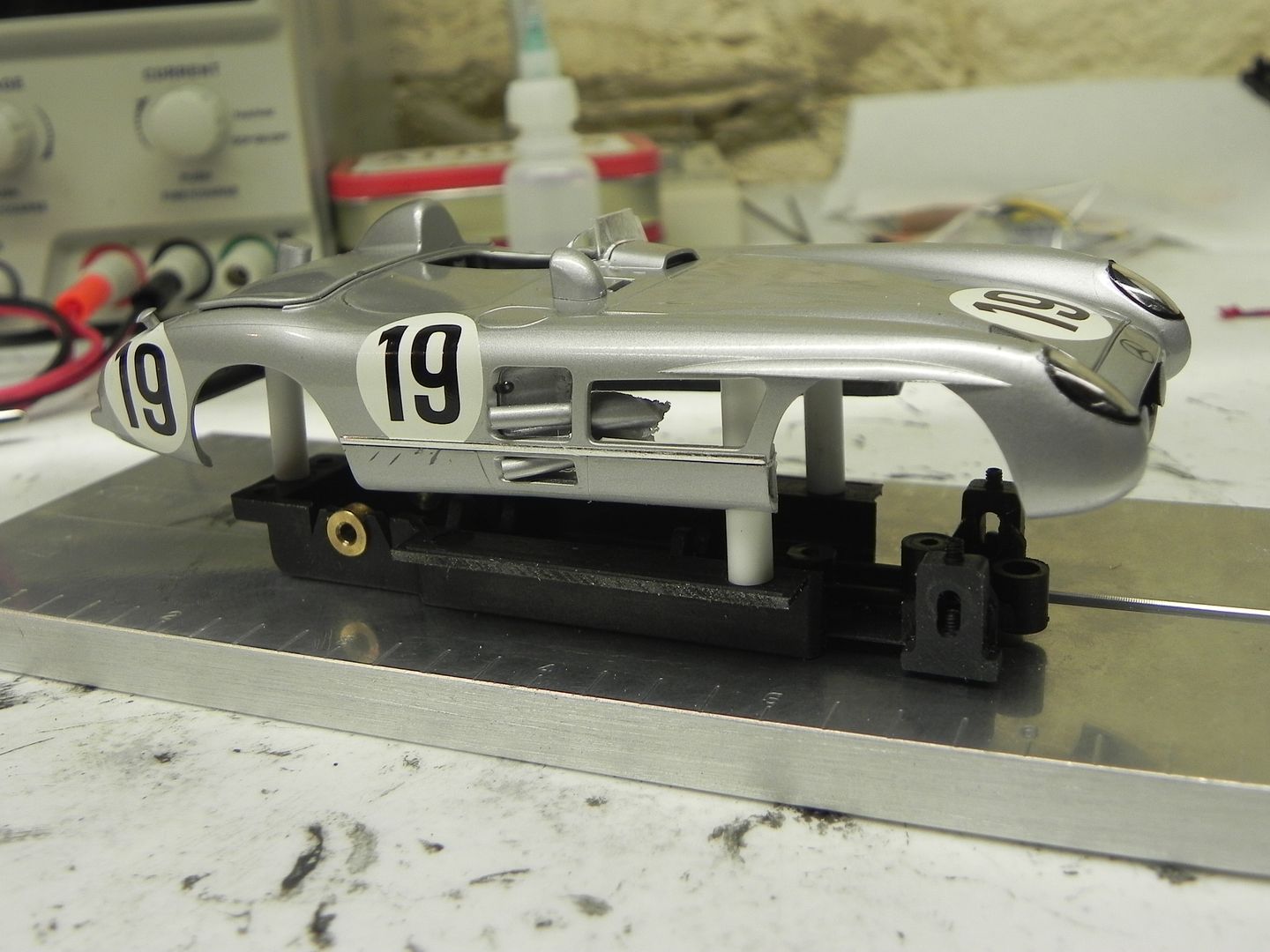

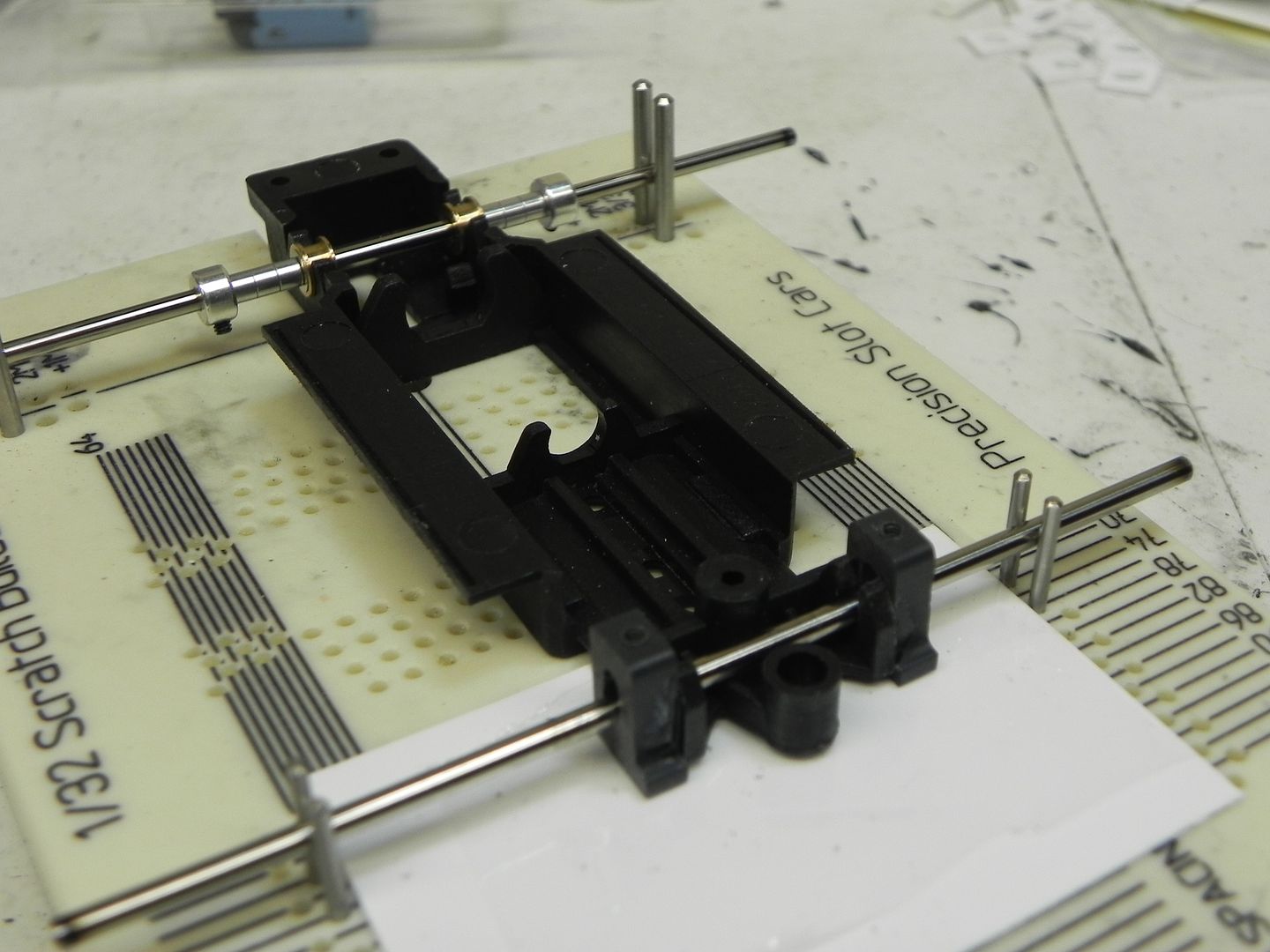

I was planning to put a Slot.It HRS2 chassis under the car, but there wasn't enough width to do it without a big chance of binding the tires on the wheel wells. So, I went a different way; one that I haven't tried yet, a PCS chassis. The first thing I wanted from this chassis, that doesn't come stock on it, was front axle adjustability. So, since the PCS chassis has the front axle mounts outboard, I used them as anchor points to add some cut-down SCC front axle blocks. It gives a good amount of surface area for the glue (Loctite 380) which is good; probably more contact surface area that if you glued them to the chassis using the standard axle block feet. I used a 1.0mm plastic sheet so that the axle blocks would not be the lowest part of the chassis (I need 3/32" chassis clearance for this proxy) and a thin layer of cellophane to prevent potential glue problems.

\

\The result is a pretty strong unit.

That's where I am now, next up is motor and gear testing. I'll post more as I go along................assuming that all goes well..................... :pray:

Allan