Is there anyway to use a dead strip with Carrera digital cars? Had to unplug my chip so laps would be counted. I was planning on a dead strip for my track, but will have to go another way if there isn't a way to make it work. I saw there are some different types of dead strips. Will any of those work? I prefer lighted cars, when available.

Edit: this is a routed not a digital track.

Harry

Dead strips issue

12 posts

• Page 1 of 1

Dead strips issue

Last edited by hksk25 on Sun Mar 04, 2018 5:39 pm, edited 1 time in total.

- hksk25

- HRW SlotCar Veteran!

- Posts: 224

- Joined: Wed Sep 05, 2012 11:05 pm

- Location: Southeastern Pennsylvania

Re: Dead strips issue

Harry if you are running digital where multiple cars use the same dead strip i cant see it working unless a transponder is used. But i am no electro wiz either.

Bob

Bob

-

chappy - Minister of Slot Racing

- Posts: 2926

- Joined: Fri Sep 28, 2012 5:22 pm

- Location: Ontario Canada

Re: Dead strips issue

Routed not digital track, I edited original message.

Harry

Harry

- hksk25

- HRW SlotCar Veteran!

- Posts: 224

- Joined: Wed Sep 05, 2012 11:05 pm

- Location: Southeastern Pennsylvania

Re: Dead strips issue

Definitely should work then Harry. Mine is routed and uses dead strip with this system

http://www.trackmateracing.com/shop/en/ ... strip.html

Bob

http://www.trackmateracing.com/shop/en/ ... strip.html

Bob

-

chappy - Minister of Slot Racing

- Posts: 2926

- Joined: Fri Sep 28, 2012 5:22 pm

- Location: Ontario Canada

Re: Dead strips issue

As an aside to this conversation, a dead strip doesn't have to disrupt power to the main rails. I put 3"-4" strips of clear gift wrap tape over the powered copper tape (rails), then put short pieces of copper tape over the clear tape for the dead strip. The clear tape insulates the upper dead strip copper rails from the powered ones below. Wider dead strip copper tape (2 overlapping pieces) allow small holes to be drilled through the dead strip tape away from the powered rails below and flat head brass bolts to used to make under table connections for the dead strip.

I drill the holes for the dead strip connections about 1/8" beside the powered rails, then put the dead strip copper tape over the holes, insert the flat head bolts through the copper tape and tighten so they are flush with the track surface. Then I put another layer of dead strip copper take over the bolt heads to ensure good conductivity.

I haven't had any loss of power problems with the main rails, and the dead strip has been flawless. If I wanted to remove it all I have to do is pull up the clear tape every thing on it would come too and everything would be back to the way it was.

Slothead

I drill the holes for the dead strip connections about 1/8" beside the powered rails, then put the dead strip copper tape over the holes, insert the flat head bolts through the copper tape and tighten so they are flush with the track surface. Then I put another layer of dead strip copper take over the bolt heads to ensure good conductivity.

I haven't had any loss of power problems with the main rails, and the dead strip has been flawless. If I wanted to remove it all I have to do is pull up the clear tape every thing on it would come too and everything would be back to the way it was.

Slothead

-

slothead - The Doctor is IN!

- Posts: 1560

- Joined: Sun Mar 17, 2013 7:04 pm

Re: Dead strips issue

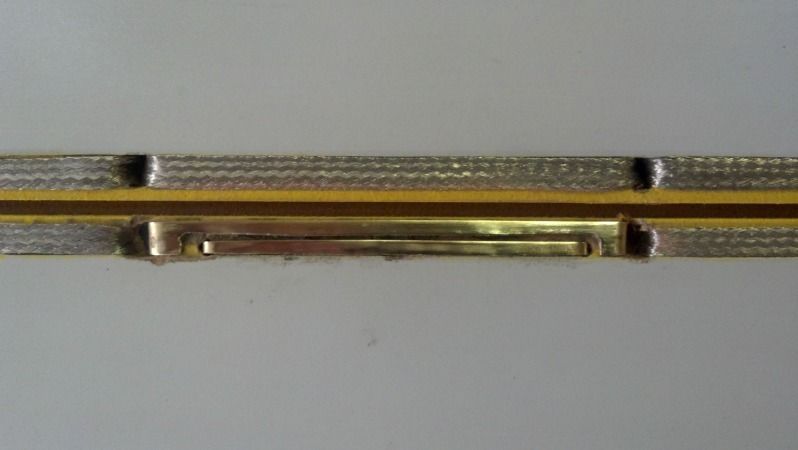

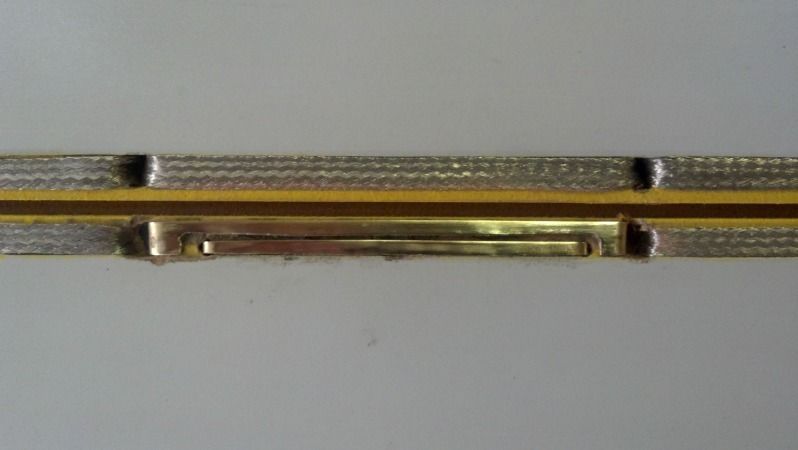

There is another type of dead strip that you can use that would eliminate your problem, plus a few others to boot, it is called a split rail dead strip.

With this arrangement one of the car's braids makes contact, power to the motor is not interrupted and no guard strips are needed. In addition it does not matter which way the car is running. If you are using Trackmate you only need to connect the powered and dead rails directly, but if you were connecting to a serial or printer port you would need to add a resistor to the circuit.

With this arrangement one of the car's braids makes contact, power to the motor is not interrupted and no guard strips are needed. In addition it does not matter which way the car is running. If you are using Trackmate you only need to connect the powered and dead rails directly, but if you were connecting to a serial or printer port you would need to add a resistor to the circuit.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

Re: Dead strips issue

How long is the sectioned off piece and how much of a gap?

Thanks, Harry

Thanks, Harry

- hksk25

- HRW SlotCar Veteran!

- Posts: 224

- Joined: Wed Sep 05, 2012 11:05 pm

- Location: Southeastern Pennsylvania

Re: Dead strips issue

From my experience, it's the chip's electronics that don't allow the "current" to flow out of the DC motor ( now generator ) to trigger the software when coasting over the dead strip.

- buspor63

- HRW SlotCar Veteran!

- Posts: 628

- Joined: Thu Sep 06, 2012 11:46 pm

Re: Dead strips issue

A couple of inches would be plenty for the dead strips themselves. If you are doing conventional dead strips with guard strips the guard strips need to be longer than the length of a car's braids, at least 3/4 of an inch. With the inline setup track voltage can't get to the electronics and guard strips are not needed.

Actually it is not the voltage generated by the car's motor that triggers a count. If you put a meter across a dead strip you will measure a voltage. When a car crosses the dead strip it creates a short circuit and the voltage drops, that is what triggers a count. If you just put a car on the dead strip and the motor was not turning that would trigger a count. The voltage generated by the motor does have an effect however. If the car is going in the wrong direction that voltage will cancel the normal voltage drop and a count could be missed. If the dead strips are not wired correctly you will often miss counts unless the car is going slowly. When that happens people assume that the problem is that the dead strips are too short, but making them longer is not the solution. If you plan on running your track in both directions you would need to put a reversing switch in the wiring that goes to each dead strip.

Serial and parallel ports do not like for a dead short to be applied across them, they can easily get burned out, the motor in the car would usually have enough resistance to avoid that problem, but to be safe there should be a resistor in the circuit. If you have Trackmate with the dead strip option that includes zener diodes to protect the electronics.

Actually it is not the voltage generated by the car's motor that triggers a count. If you put a meter across a dead strip you will measure a voltage. When a car crosses the dead strip it creates a short circuit and the voltage drops, that is what triggers a count. If you just put a car on the dead strip and the motor was not turning that would trigger a count. The voltage generated by the motor does have an effect however. If the car is going in the wrong direction that voltage will cancel the normal voltage drop and a count could be missed. If the dead strips are not wired correctly you will often miss counts unless the car is going slowly. When that happens people assume that the problem is that the dead strips are too short, but making them longer is not the solution. If you plan on running your track in both directions you would need to put a reversing switch in the wiring that goes to each dead strip.

Serial and parallel ports do not like for a dead short to be applied across them, they can easily get burned out, the motor in the car would usually have enough resistance to avoid that problem, but to be safe there should be a resistor in the circuit. If you have Trackmate with the dead strip option that includes zener diodes to protect the electronics.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

Re: Dead strips issue

I use the dead strip I described above to 'left click' a mouse which creates a split time on a stopwatch program downloaded from the internet. I got this idea from a post on HRW about how to use a mouse to count and time laps. As a solo racer I only need the left click to create a list of split times for lap times.

Split 1: 00:00:29 (677) # lap time

Split 2: 00:00:39 (868) 1 10.19

Split 3: 00:00:50 (158) 2 10.29

Split 4: 00:01:00 (415) 3 10.26

Split 5: 00:01:10 (474) 4 10.06

Split 6: 00:01:20 (632) 5 10.16

I use an Excel spreadsheet to subtract each line from the one above it to get individual lap times, after skipping the start time.

Slothead

Split 1: 00:00:29 (677) # lap time

Split 2: 00:00:39 (868) 1 10.19

Split 3: 00:00:50 (158) 2 10.29

Split 4: 00:01:00 (415) 3 10.26

Split 5: 00:01:10 (474) 4 10.06

Split 6: 00:01:20 (632) 5 10.16

I use an Excel spreadsheet to subtract each line from the one above it to get individual lap times, after skipping the start time.

Slothead

-

slothead - The Doctor is IN!

- Posts: 1560

- Joined: Sun Mar 17, 2013 7:04 pm

Re: Dead strips issue

I will have to make note of that procedure. If you are using a more sophisticated computer based system that will display your best lap time. Trackmate will also display your mean lap time. In some cases a car might be difficult to drive and you will not see consistent lap times. You might be able to put together a fast lap once in a while, but the mean time will tell you more. Taking things a step further Race Coordinator can save every single lap of every driver to an Excell spread sheet. I have that data for a 24 hour race that I ran in last year. I looked over the data to determine which team had the best drivers. Since each team used a different car the total laps for each team would not tell you that. Going through the entire race lap by lap I could compare how each driver did with the same car, I could also determine how consistent each driver was and how many crashes they had.

-

RichD - HRW SlotCar Veteran!

- Posts: 1885

- Joined: Thu Sep 06, 2012 7:41 am

- Location: East Haven, CT

12 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 9 guests