3D printed body

7 posts

• Page 1 of 1

3D printed body

I was just curious, has anyone tried to make a car body using a 3D printer.

- RA race fan

- Posts: 4

- Joined: Fri Feb 27, 2015 11:16 pm

Re: 3D printed body

Check posts by Choc-ice. He has made a few.

-

Modlerbob - HRW SlotCar Veteran!

- Posts: 1996

- Joined: Thu Sep 06, 2012 12:45 am

- Location: DeBary, Florida

Re: 3D printed body

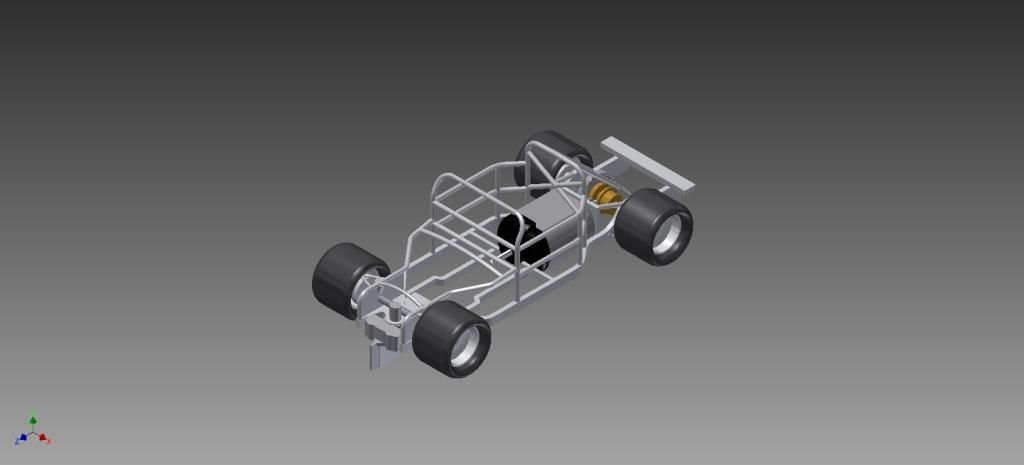

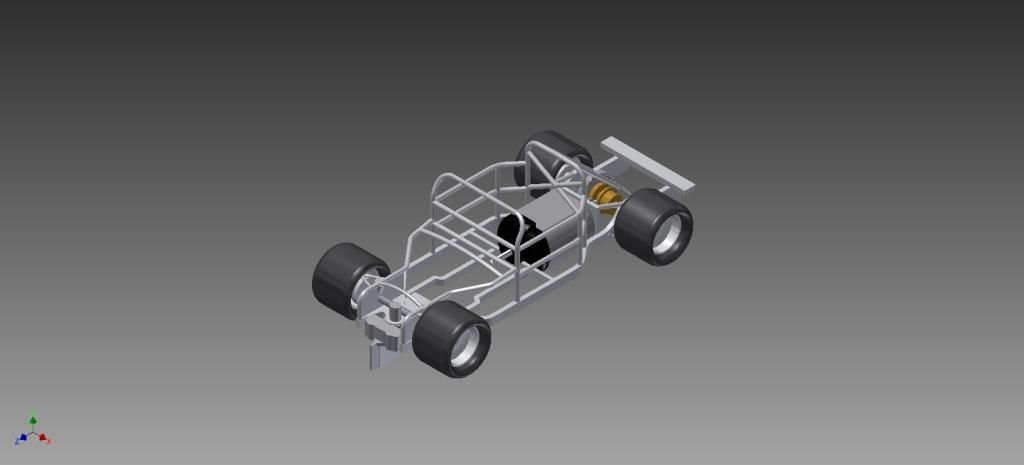

Yes I have.  I must admit it wasn't the best but I am still learning after two printers in two years. I am currently using a printer that uses the 3mm filament and so far I am more satisfied with it. The Printers that I use heat up the ABS filament and extrudes it it. I first model it up in Inventor, then do an analysis and then print it out. This can take me up to three weeks by just working on it a few hours each day. The biggest issue is putting in support into the model so the printer can print it without the droop or stray extrusions

I must admit it wasn't the best but I am still learning after two printers in two years. I am currently using a printer that uses the 3mm filament and so far I am more satisfied with it. The Printers that I use heat up the ABS filament and extrudes it it. I first model it up in Inventor, then do an analysis and then print it out. This can take me up to three weeks by just working on it a few hours each day. The biggest issue is putting in support into the model so the printer can print it without the droop or stray extrusions

As far as bodies goes, it will take some time and experimenting to get it so I am working on the chassis' first. The first body I did was an Ugly Falcon. I modeled it up from memory and pictures I found on the internet. Then I sliced it up, printed out the parts and glued it together. I also printed out the chassis for it. It weighed around 120 grams but it ran pretty good on my track but it would be for private running for it would be to embarrassing to run with other people watching for it turned a mid 9 second lap on my track. I also picked up a 3d scanner to scan 1/25 bodies and scale those down to 1/32. But then that is another learning process due to having to set the body up correctly to get a complete scan.

Hopefully this helps.

I must admit it wasn't the best but I am still learning after two printers in two years. I am currently using a printer that uses the 3mm filament and so far I am more satisfied with it. The Printers that I use heat up the ABS filament and extrudes it it. I first model it up in Inventor, then do an analysis and then print it out. This can take me up to three weeks by just working on it a few hours each day. The biggest issue is putting in support into the model so the printer can print it without the droop or stray extrusions

I must admit it wasn't the best but I am still learning after two printers in two years. I am currently using a printer that uses the 3mm filament and so far I am more satisfied with it. The Printers that I use heat up the ABS filament and extrudes it it. I first model it up in Inventor, then do an analysis and then print it out. This can take me up to three weeks by just working on it a few hours each day. The biggest issue is putting in support into the model so the printer can print it without the droop or stray extrusions

As far as bodies goes, it will take some time and experimenting to get it so I am working on the chassis' first. The first body I did was an Ugly Falcon. I modeled it up from memory and pictures I found on the internet. Then I sliced it up, printed out the parts and glued it together. I also printed out the chassis for it. It weighed around 120 grams but it ran pretty good on my track but it would be for private running for it would be to embarrassing to run with other people watching for it turned a mid 9 second lap on my track. I also picked up a 3d scanner to scan 1/25 bodies and scale those down to 1/32. But then that is another learning process due to having to set the body up correctly to get a complete scan.

Hopefully this helps.

-

ccobra - HRW SlotCar Veteran!

- Posts: 751

- Joined: Sun Feb 16, 2014 3:56 pm

- Location: Central valley in California

Re: 3D printed body

The chassis with the roll cage looks awesome, any more pictures?

-

Alaskaracer - HRW SlotCar Veteran!

- Posts: 195

- Joined: Wed Sep 05, 2012 4:08 pm

- Location: Howey In the Hills, FL

Re: 3D printed body

Here's a teaser,  After I mow the lawn, I plan on working more on it with a dremel and xacto knife to cut out the supports. I might leave the one support in for the firewall depending on how it looks. I plan on putting a piranha motor in it.

After I mow the lawn, I plan on working more on it with a dremel and xacto knife to cut out the supports. I might leave the one support in for the firewall depending on how it looks. I plan on putting a piranha motor in it.

After I mow the lawn, I plan on working more on it with a dremel and xacto knife to cut out the supports. I might leave the one support in for the firewall depending on how it looks. I plan on putting a piranha motor in it.

After I mow the lawn, I plan on working more on it with a dremel and xacto knife to cut out the supports. I might leave the one support in for the firewall depending on how it looks. I plan on putting a piranha motor in it.-

ccobra - HRW SlotCar Veteran!

- Posts: 751

- Joined: Sun Feb 16, 2014 3:56 pm

- Location: Central valley in California

Re: 3D printed body

Yes, I've made close to a dozen different bodyshells, all used as masters for resin casting. A 3D printed shell is too heavy and far too expensive to use on the track, although an SLS shell comes close. Here's one straight off the printer

And after some cleaning up and smoothing off (I'm getting better at this now!) the resin casting comes out

Easy, huh?

And after some cleaning up and smoothing off (I'm getting better at this now!) the resin casting comes out

Easy, huh?

- choc-ice

- HRW SlotCar Veteran!

- Posts: 239

- Joined: Thu Sep 06, 2012 1:33 pm

Re: 3D printed body

Boy, you do nice work!

Allan

Allan

-

Audi1 - HRW SlotCar Veteran!

- Posts: 4223

- Joined: Fri Nov 01, 2013 7:25 am

- Location: Merrimac, MA

7 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 5 guests