Scalextric Mercedes-Benz 300 SLR build

39 posts

• Page 2 of 3 • 1, 2, 3

Re: Scalextric Mercedes-Benz 300 SLR build

Allan - great looking build so far! Cutting the rockers off and gluing them to the body is the way to go on these types of cars.

-

dreinecke - King of the Dum-Dums!

- Posts: 7360

- Joined: Wed Aug 08, 2012 5:39 pm

- Location: Colorado

Re: Scalextric Mercedes-Benz 300 SLR build

Brass hub 23 tooth crowns on order now - thanks!

Allan

Allan

-

Audi1 - HRW SlotCar Veteran!

- Posts: 4223

- Joined: Fri Nov 01, 2013 7:25 am

- Location: Merrimac, MA

Re: Scalextric Mercedes-Benz 300 SLR build

This is a great build thread Allan!

Great pics and details! Thanks for sharing! :D

Great pics and details! Thanks for sharing! :D

-

TuscoTodd - HRW Bouncer

- Posts: 7145

- Joined: Sat Aug 17, 2013 11:25 am

- Location: Rural Ohio

Re: Scalextric Mercedes-Benz 300 SLR build

A little more progress.

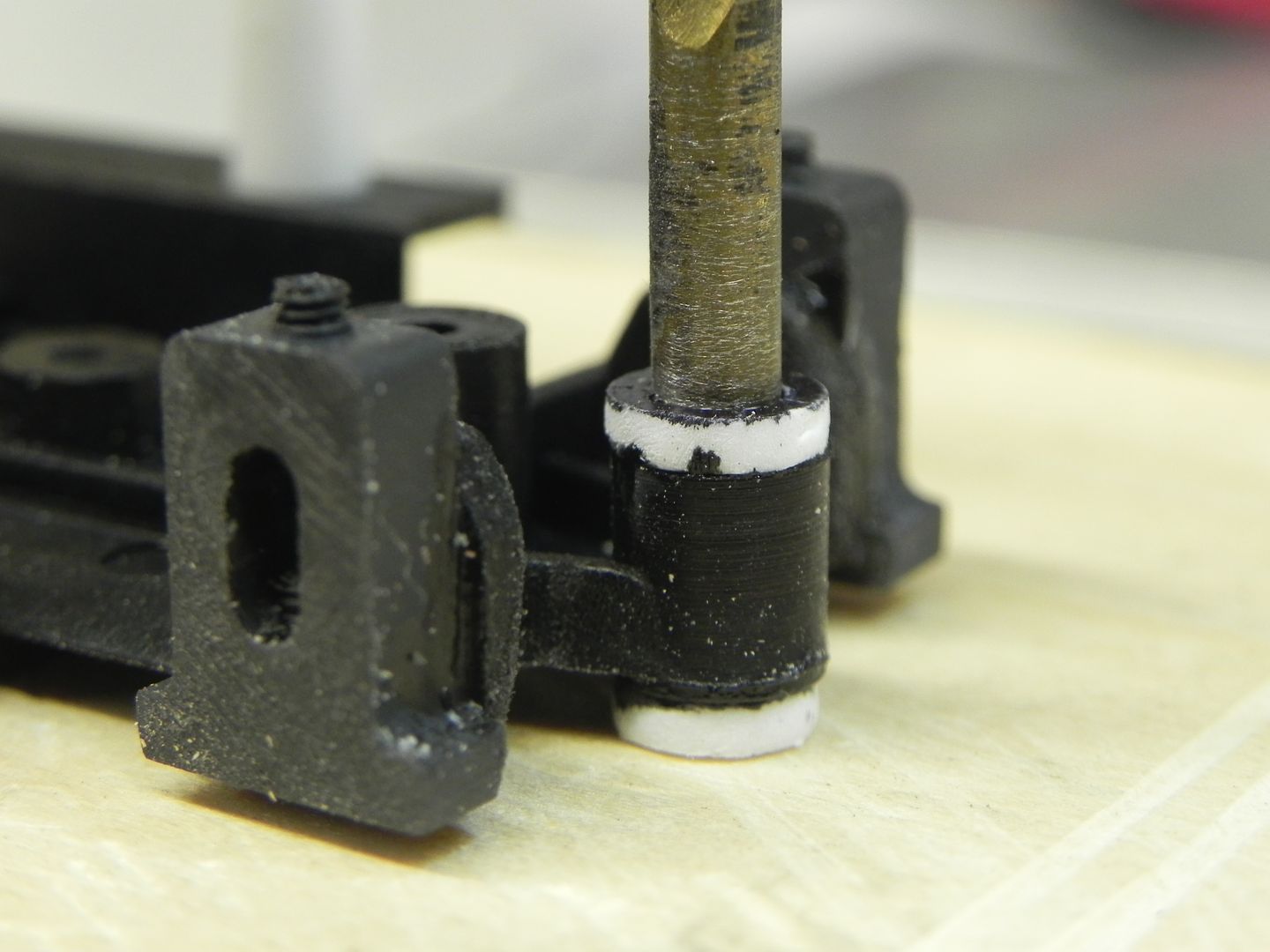

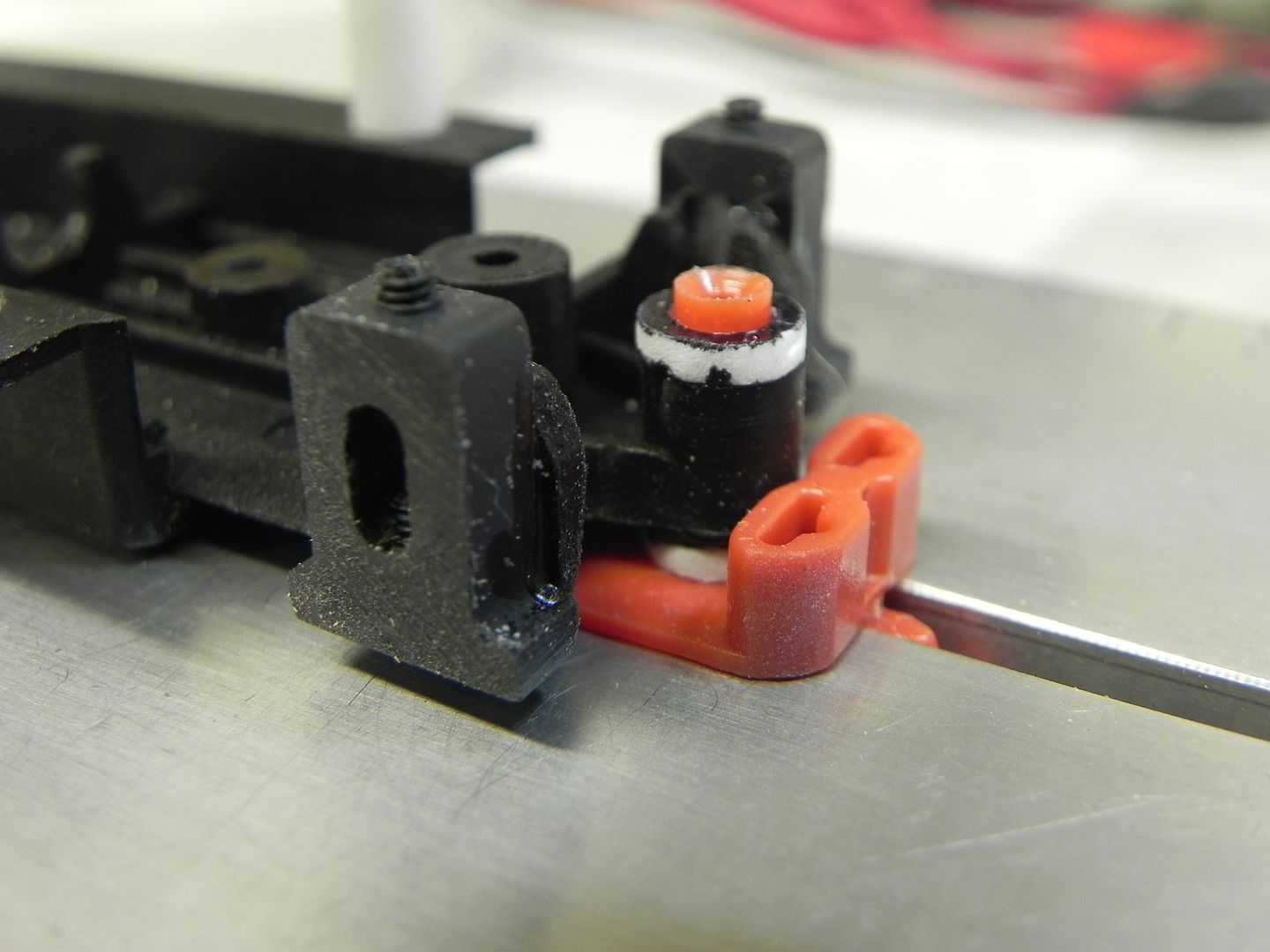

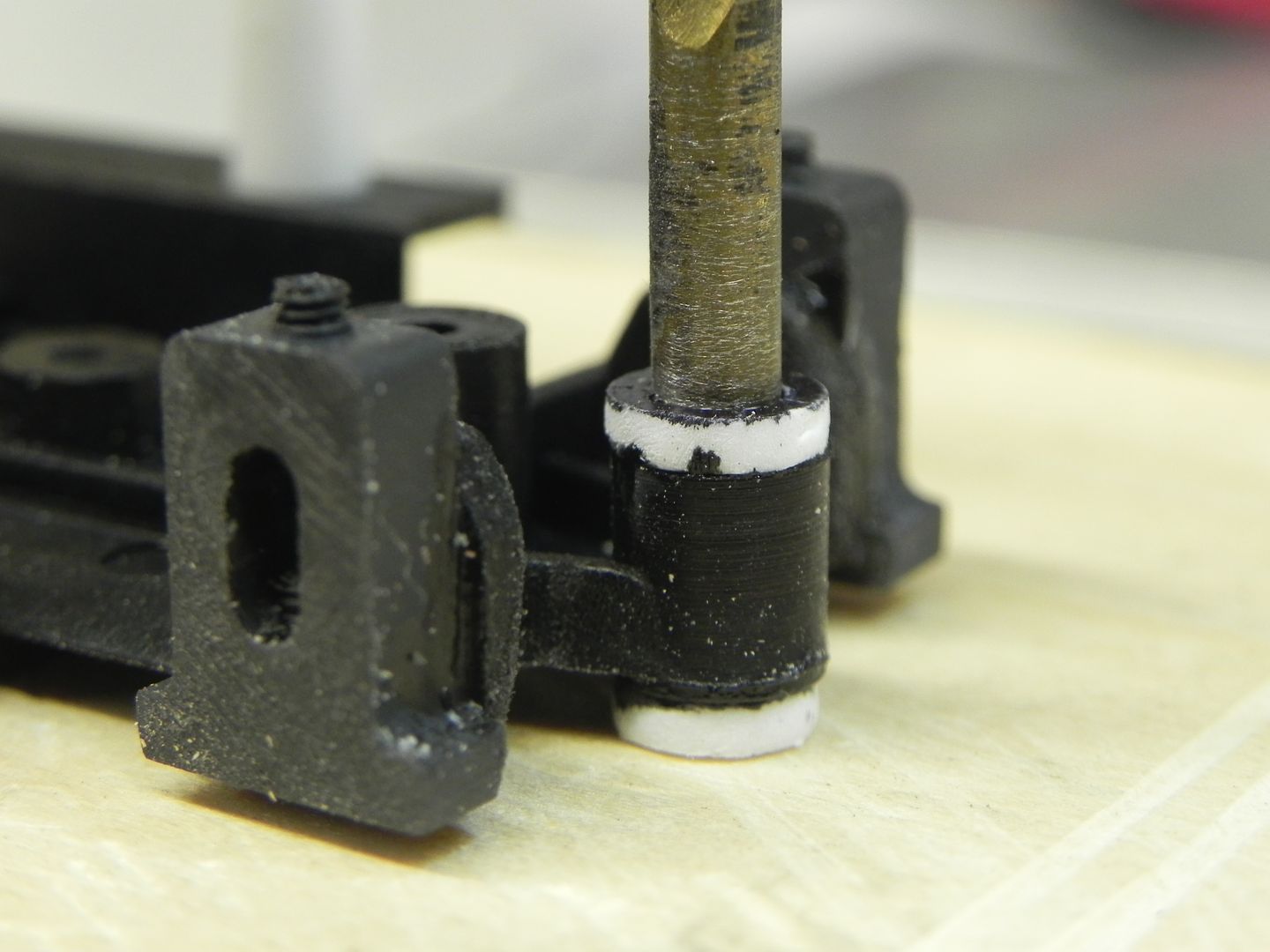

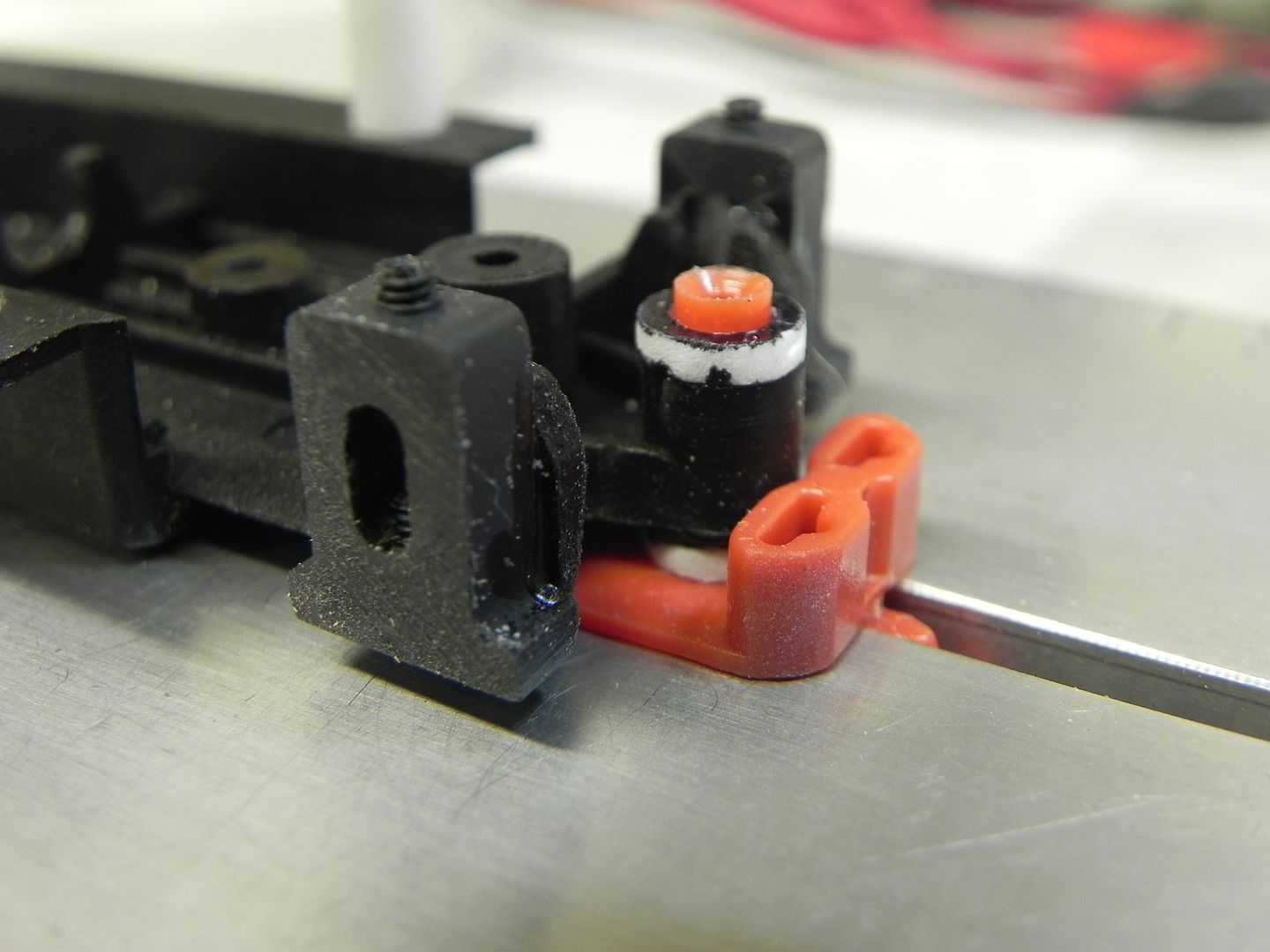

The PCS chassis comes with a guide hole that's 3.7+mm wide. The guide that I wanted to use is the Scaleauto 1607 and it comes with a guide post that's 3.55mm wide. So, time for some spacers.

I'm not a fan of stacking the commercially available spacers under a chassis, so I made up my own from 1.5mm styrene sheet. Thanks to some guidance from Dennis (gascarnut) a #27 drill bit is almost exactly 3.55mm in diameter. So, the guide spacer fabrication consisted of drilling holes in the 1.5mm styrene sheet with the #27 bit, using scissors to trim up the outside of the spacer and finishing the outside off with fine sandpaper. The result was pretty good.

The spacers are glued in place using Loctite 380 and I made a simple gluing jig from a piece of 1x4 with the #27 bit inserted into its own hole. Then glue was applied first to the bottom of the chassis guide hole area and the chassis was pressed down on the bottom spacer, then to the top of the chassis guide hole area and the upper spacer was pushed down on top of it.

With the guide in place, there is now good, free movement of the guide post in the spacer holes and there is no slop in the guide itself, either front-to-back or side-to-side.

I'll do the final trim on the guide post once I have the guide height finalized.

Next up; body on.

Allan

The PCS chassis comes with a guide hole that's 3.7+mm wide. The guide that I wanted to use is the Scaleauto 1607 and it comes with a guide post that's 3.55mm wide. So, time for some spacers.

I'm not a fan of stacking the commercially available spacers under a chassis, so I made up my own from 1.5mm styrene sheet. Thanks to some guidance from Dennis (gascarnut) a #27 drill bit is almost exactly 3.55mm in diameter. So, the guide spacer fabrication consisted of drilling holes in the 1.5mm styrene sheet with the #27 bit, using scissors to trim up the outside of the spacer and finishing the outside off with fine sandpaper. The result was pretty good.

The spacers are glued in place using Loctite 380 and I made a simple gluing jig from a piece of 1x4 with the #27 bit inserted into its own hole. Then glue was applied first to the bottom of the chassis guide hole area and the chassis was pressed down on the bottom spacer, then to the top of the chassis guide hole area and the upper spacer was pushed down on top of it.

With the guide in place, there is now good, free movement of the guide post in the spacer holes and there is no slop in the guide itself, either front-to-back or side-to-side.

I'll do the final trim on the guide post once I have the guide height finalized.

Next up; body on.

Allan

-

Audi1 - HRW SlotCar Veteran!

- Posts: 4223

- Joined: Fri Nov 01, 2013 7:25 am

- Location: Merrimac, MA

Re: Scalextric Mercedes-Benz 300 SLR build

I really get lazy with my spacers for if I was to try and cut them out with scissors and sand them round they would be more egg shaped. I use a leather punch for the outside dimension and then drill the hole at the dimple which is centered.

-

ccobra - HRW SlotCar Veteran!

- Posts: 751

- Joined: Sun Feb 16, 2014 3:56 pm

- Location: Central valley in California

Re: Scalextric Mercedes-Benz 300 SLR build

Now THAT is good work! Nice solution!

-

dreinecke - King of the Dum-Dums!

- Posts: 7360

- Joined: Wed Aug 08, 2012 5:39 pm

- Location: Colorado

Re: Scalextric Mercedes-Benz 300 SLR build

Yes, fine work. That is the same way I have made spacers over the years. Sometimes not everything is "plug and play" and we need to get a little messy. That's half the fun sometimes :)

For thinner shims, try the cheap plastic yard sale/for rent signs at Wal Mart. This is good plastic for making flares, assorted hood scoops, visors and interior trays. I have now found them at Dollar Tree and Dollar General.

Again, well done.

For thinner shims, try the cheap plastic yard sale/for rent signs at Wal Mart. This is good plastic for making flares, assorted hood scoops, visors and interior trays. I have now found them at Dollar Tree and Dollar General.

Again, well done.

-

HomeRacingWorld - HRW Janitor

- Posts: 15569

- Joined: Wed Aug 08, 2012 2:05 pm

- Location: HRW Skunkworks

Re: Scalextric Mercedes-Benz 300 SLR build

Well, we have a lower rider now.............

This is the part of building that I think I like the least: measure, cut, sand, re-position / measure, cut, sand, re-position / repeat...................

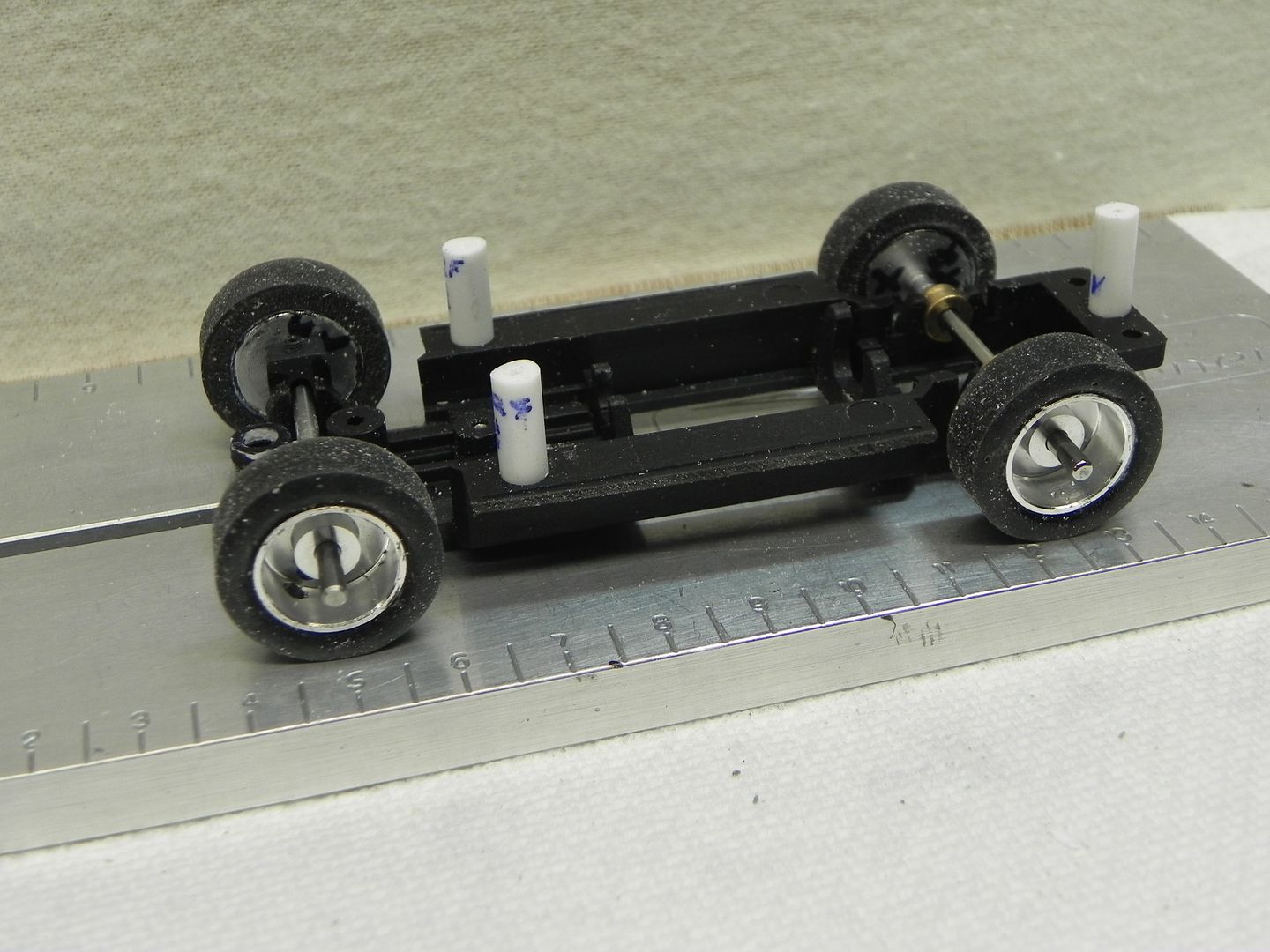

Sized body posts:

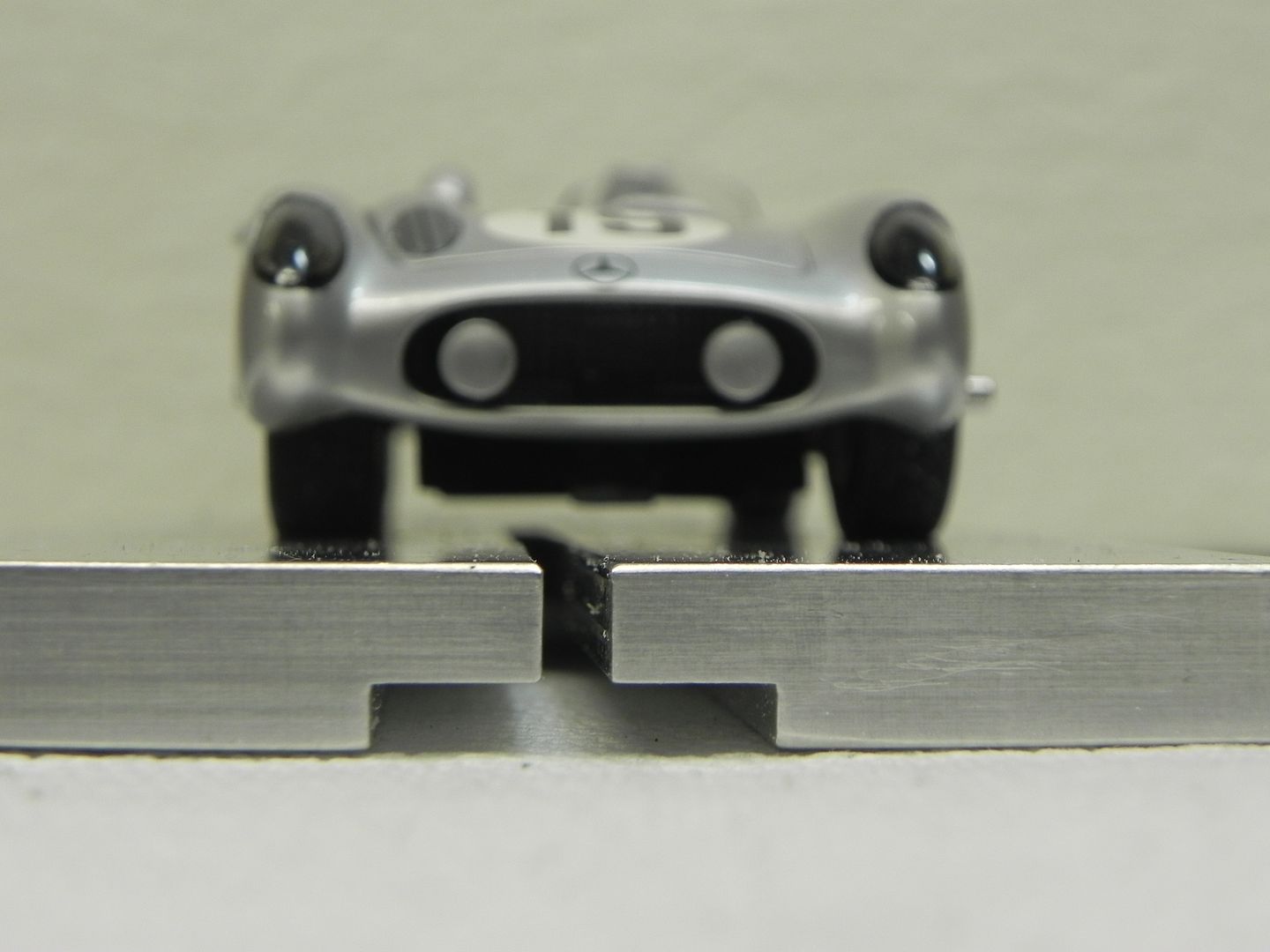

Body in position:

Could be a little high in the rear, but with body roll, I prefer it that way, rather than having to worry about tire chafe or cutting.

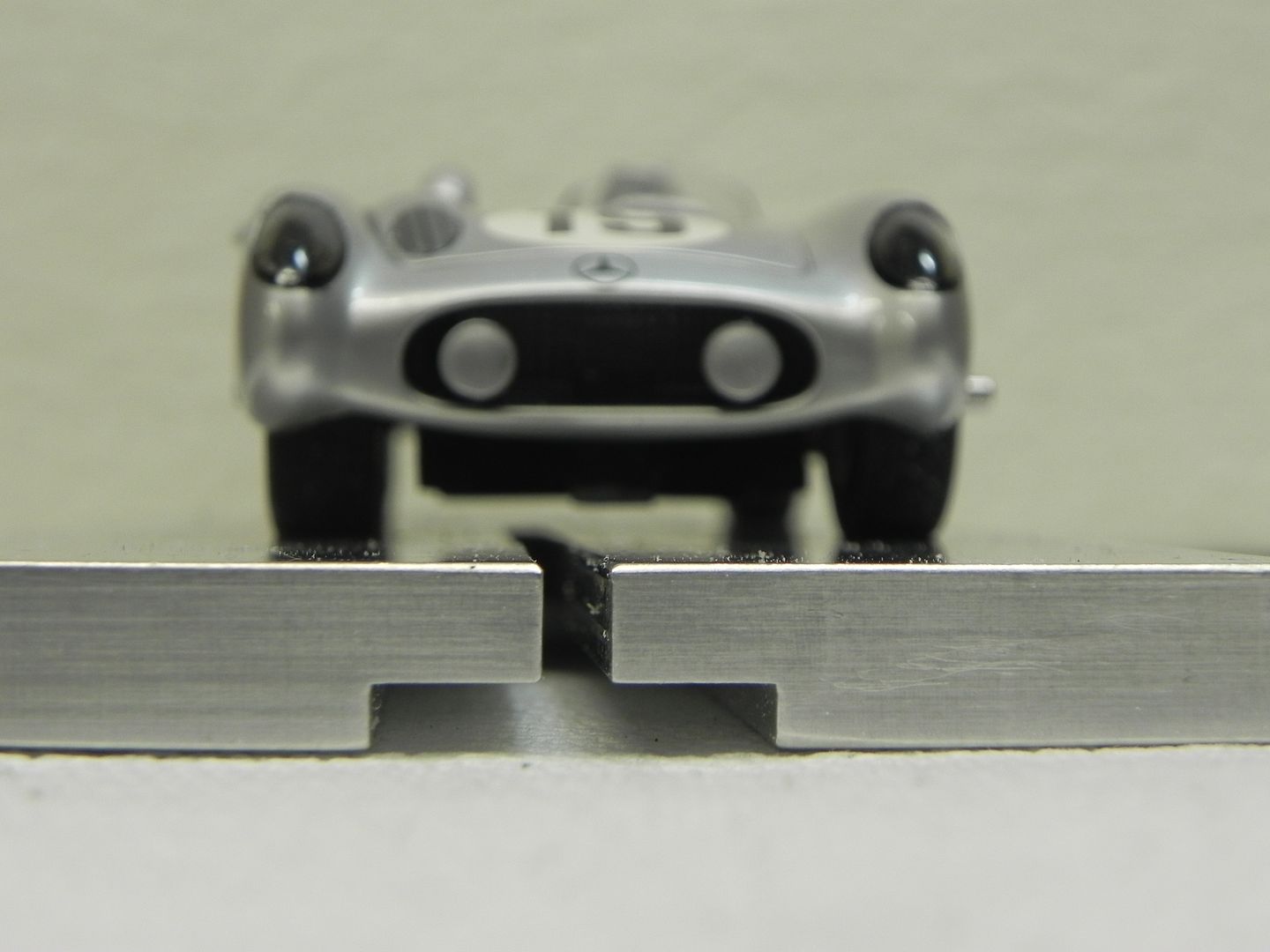

Blurry Front on (the camera focused on the front of the set up block instead of the front of the car). Guess I could say that it was going too fast, or too slow, to get a good pic: :lol:

Next up, the finishing details.

Allan

This is the part of building that I think I like the least: measure, cut, sand, re-position / measure, cut, sand, re-position / repeat...................

Sized body posts:

Body in position:

Could be a little high in the rear, but with body roll, I prefer it that way, rather than having to worry about tire chafe or cutting.

Blurry Front on (the camera focused on the front of the set up block instead of the front of the car). Guess I could say that it was going too fast, or too slow, to get a good pic: :lol:

Next up, the finishing details.

Allan

-

Audi1 - HRW SlotCar Veteran!

- Posts: 4223

- Joined: Fri Nov 01, 2013 7:25 am

- Location: Merrimac, MA

Re: Scalextric Mercedes-Benz 300 SLR build

Looks great, I like the back end a little higher also. It doesn't effect the looks and keeps the rears off the fenders.

- loosewheel

- HRW SlotCar Veteran!

- Posts: 312

- Joined: Fri Dec 05, 2014 1:32 pm

Re: Scalextric Mercedes-Benz 300 SLR build

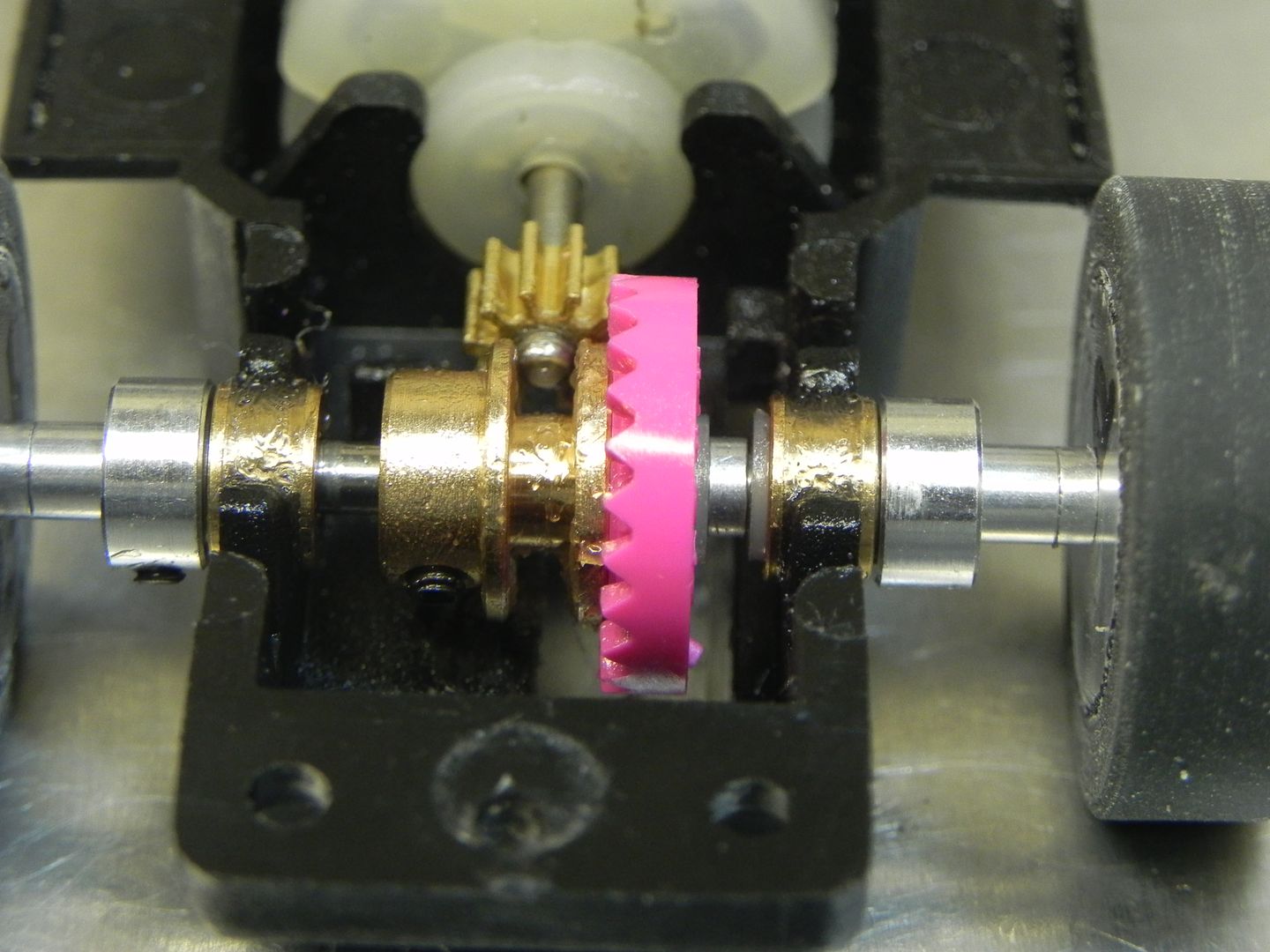

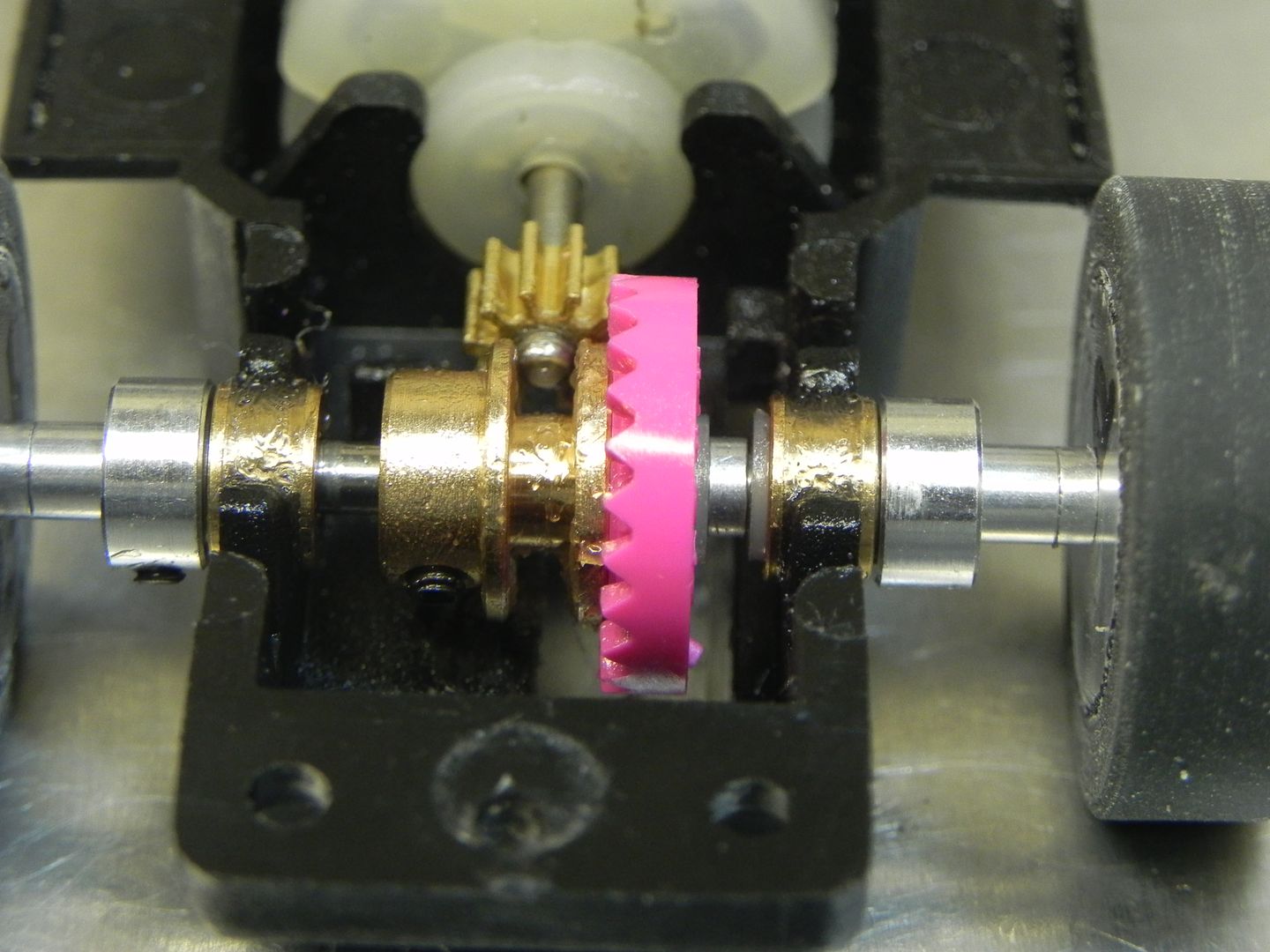

At one point on this thread, the topic of an aluminum hub crown gear vs. a brass hub came up and, in the end, and after talking with a lot of people, I changed out the aluminum hub for a brass one. I seldomly worry about stripped crowns though, because I use a belt and suspenders approach to keeping the crown and the pinion aligned. Here's a pic that shows what I do for IL motored cars:

If you look closely to the right of the crown face, you'll see three spacers; an 0.02", an 0.05" and another 0.02: on the axle between the crown face and the inside bushing face. This is not a tight fit, I leave just a little play. Then I fine tune with the axle stoppers that you can see on the outside faces of the bushings. It makes for a pretty secure unit. I probably could have stayed with the aluminum hub safely; which I prefer because it weighs less and, therefore, gives less drive train resistance. But, for this car, I went with the brass hub.

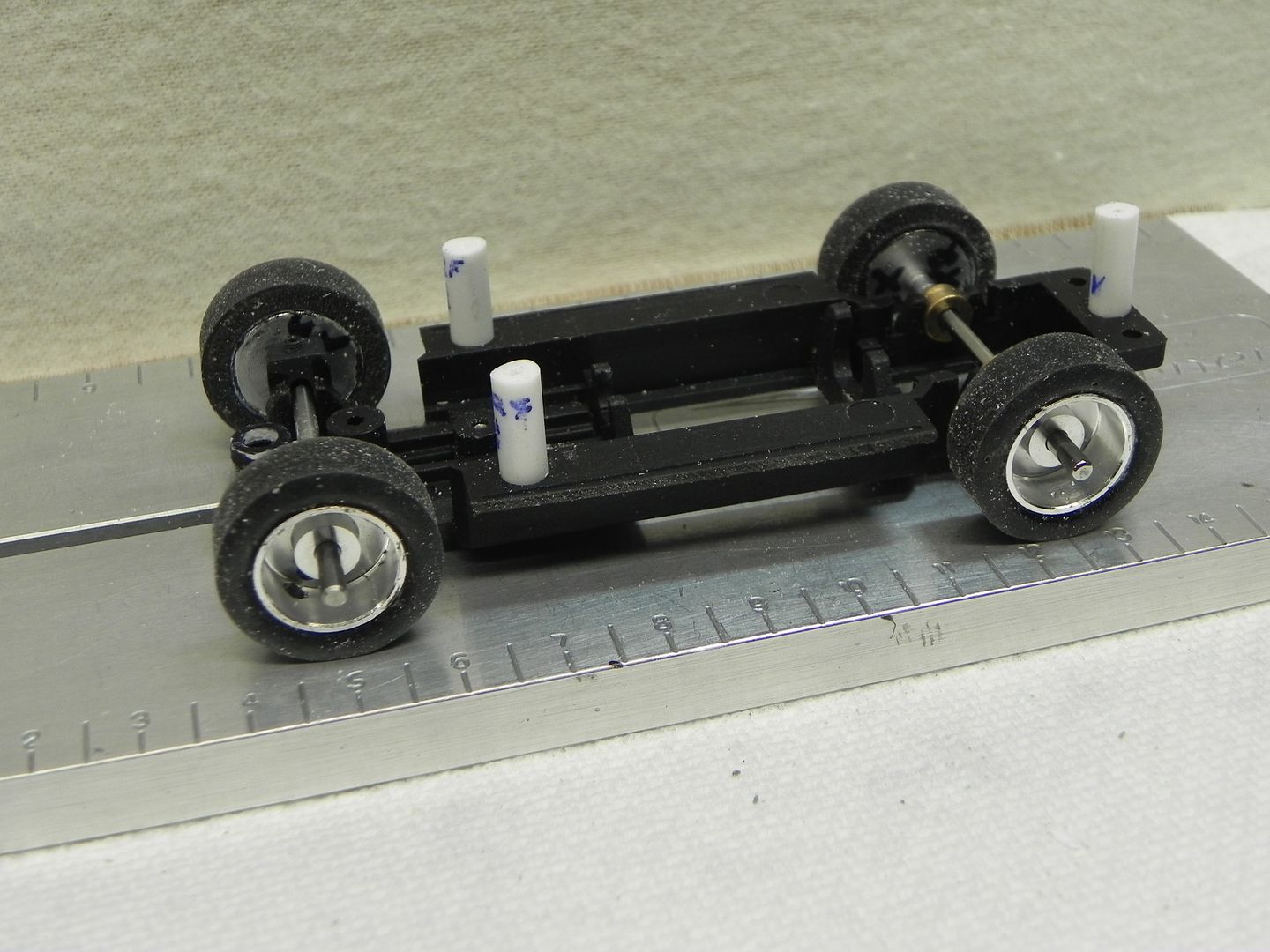

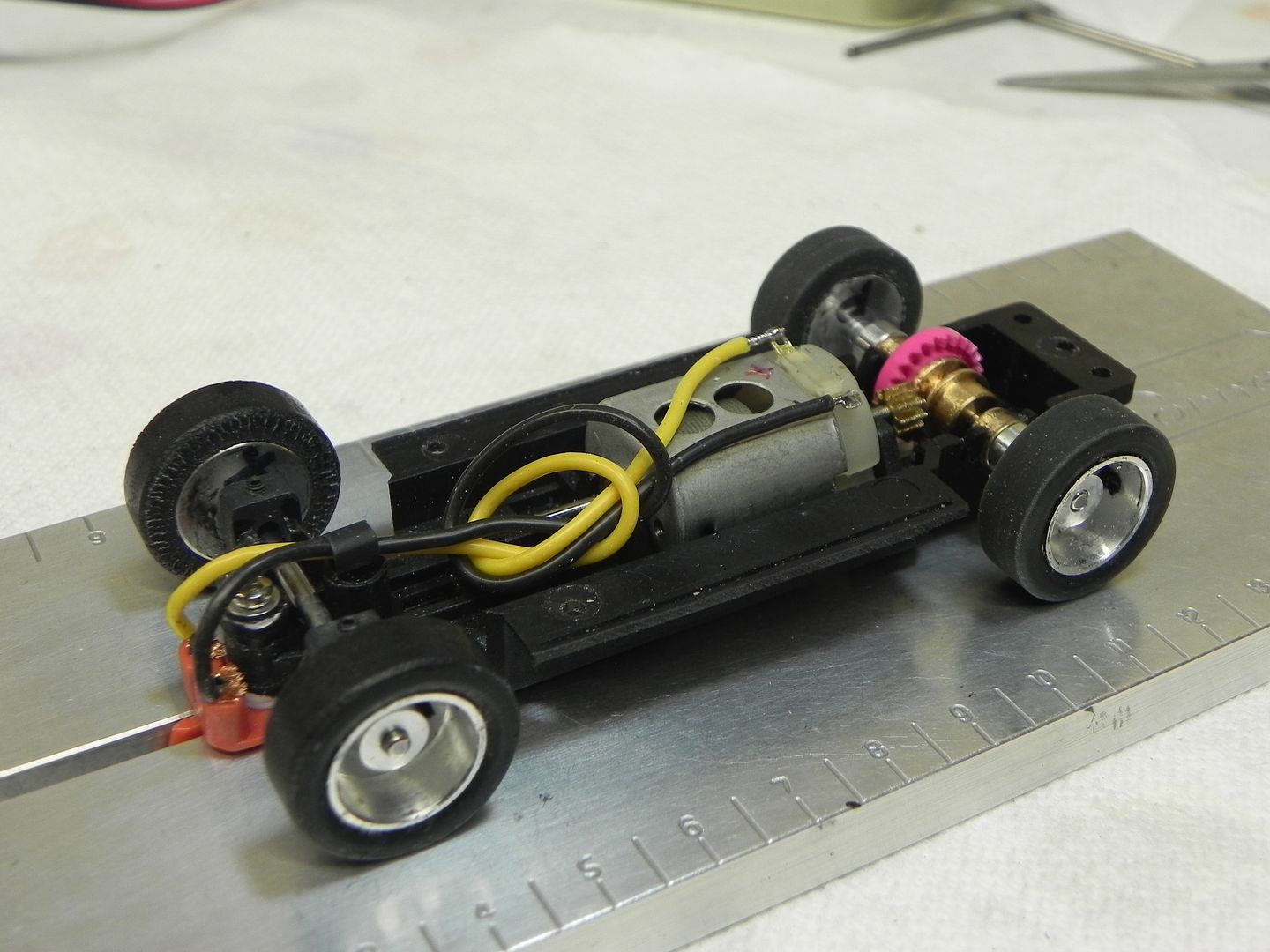

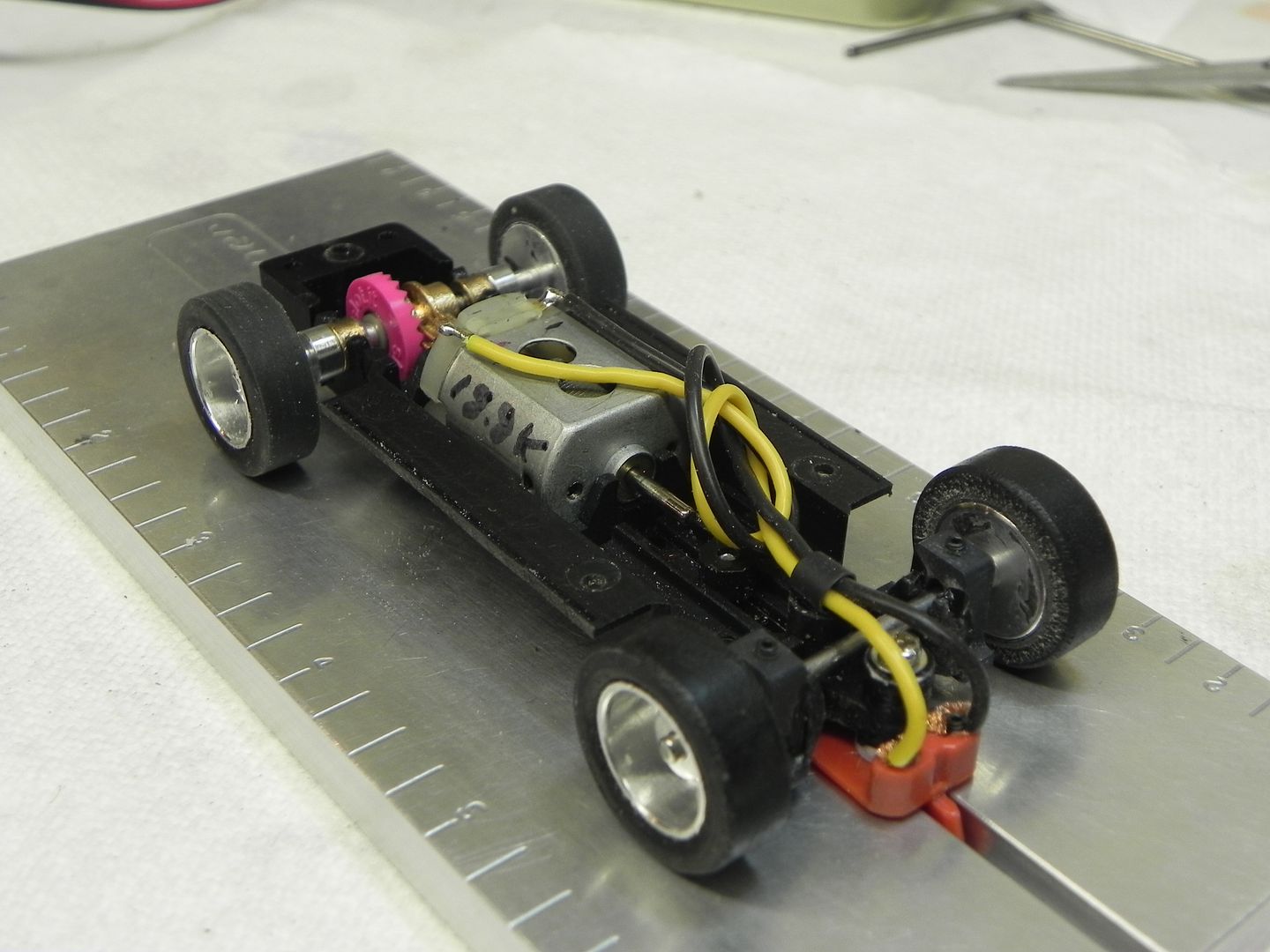

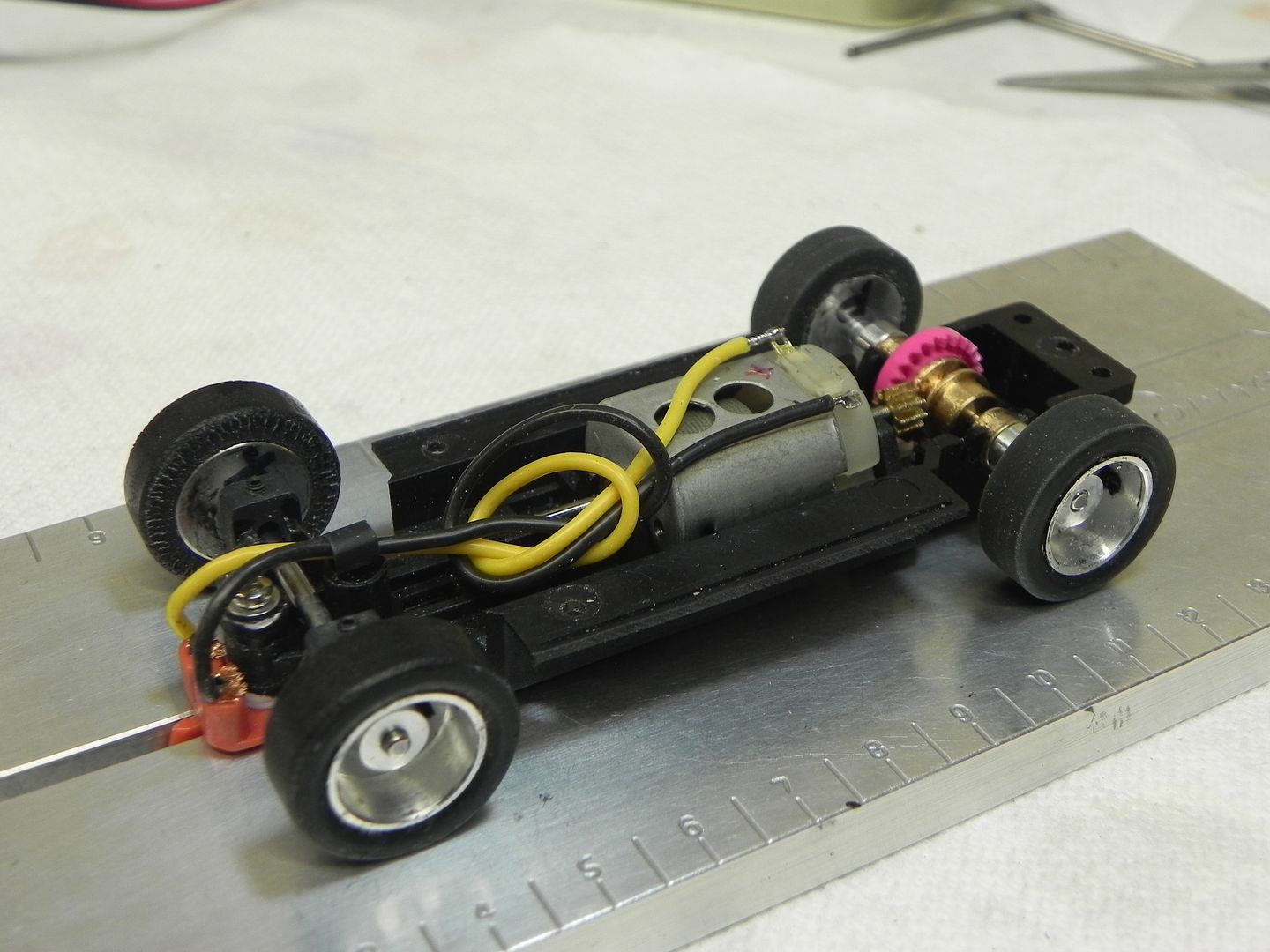

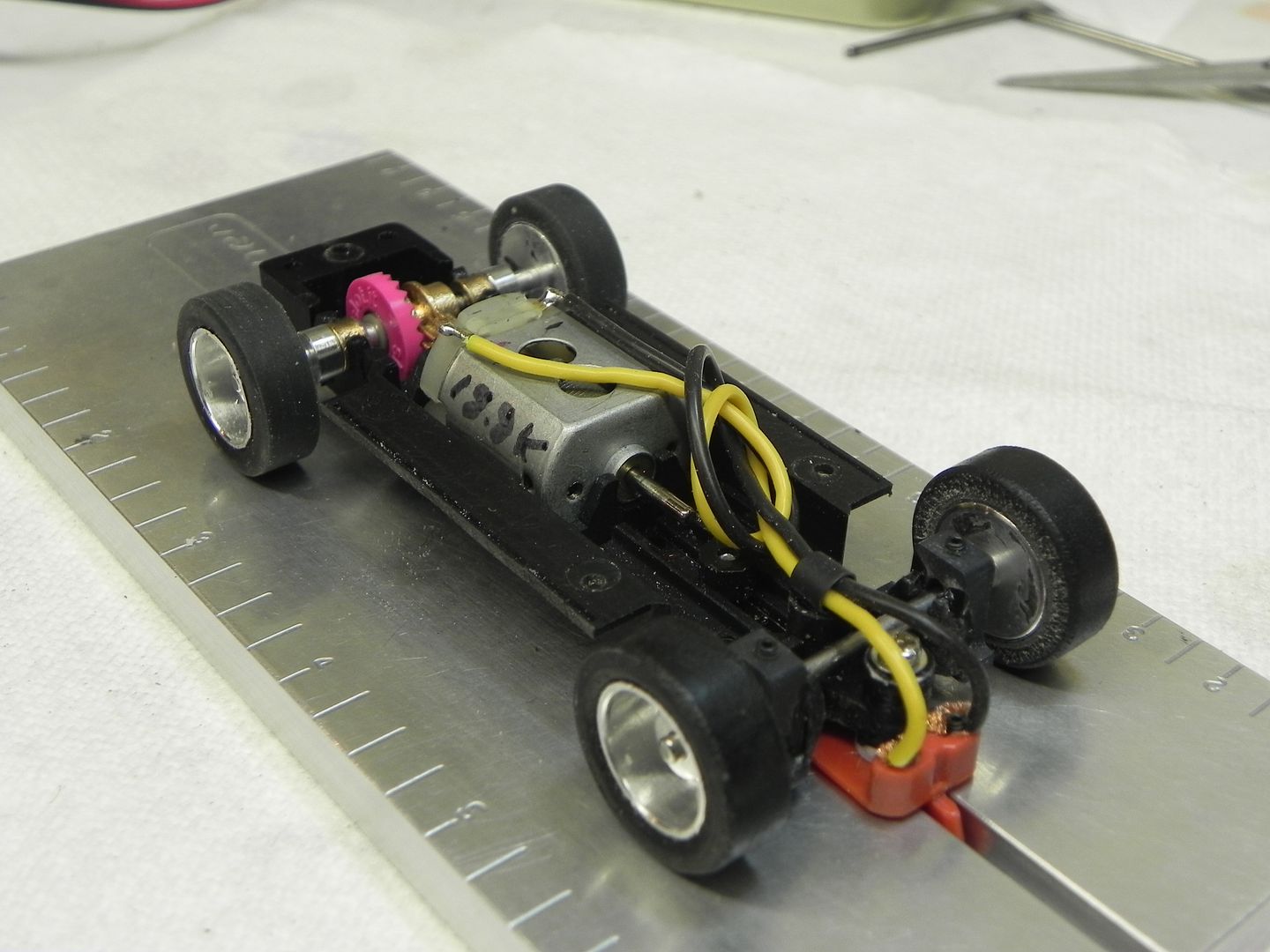

Here are a couple pics of the running chassis:

And a couple of the car with the body mounted on the chassis:

It's a fairly light car right now; 70.4g with the chassis mounted to the body. I need to do some tire testing this weekend, followed by some weight testing. Once that's done I can mount the wire wheel inserts and it will be ready to be shipped out for the race. Seems the more time you have, the more tinkering you do...........................

Allan

If you look closely to the right of the crown face, you'll see three spacers; an 0.02", an 0.05" and another 0.02: on the axle between the crown face and the inside bushing face. This is not a tight fit, I leave just a little play. Then I fine tune with the axle stoppers that you can see on the outside faces of the bushings. It makes for a pretty secure unit. I probably could have stayed with the aluminum hub safely; which I prefer because it weighs less and, therefore, gives less drive train resistance. But, for this car, I went with the brass hub.

Here are a couple pics of the running chassis:

And a couple of the car with the body mounted on the chassis:

It's a fairly light car right now; 70.4g with the chassis mounted to the body. I need to do some tire testing this weekend, followed by some weight testing. Once that's done I can mount the wire wheel inserts and it will be ready to be shipped out for the race. Seems the more time you have, the more tinkering you do...........................

Allan

-

Audi1 - HRW SlotCar Veteran!

- Posts: 4223

- Joined: Fri Nov 01, 2013 7:25 am

- Location: Merrimac, MA

Re: Scalextric Mercedes-Benz 300 SLR build

That is coming along nicely Allan!

-

dge467 - The King of Foil

- Posts: 3636

- Joined: Tue Sep 04, 2012 9:07 pm

- Location: N.E. Massachusetts

Re: Scalextric Mercedes-Benz 300 SLR build

Very Nice Build Allan, I like that body style a lot.

your driveline looks bullet proof. great work.

Bob

your driveline looks bullet proof. great work.

Bob

-

btaylor - Uncle Bob

- Posts: 4519

- Joined: Mon Mar 24, 2014 3:50 am

39 posts

• Page 2 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 1 guest