​

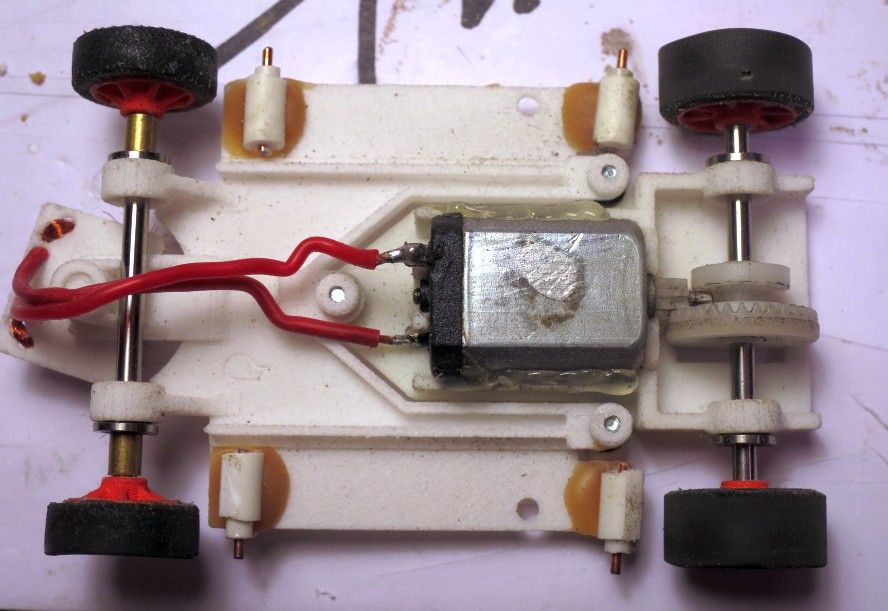

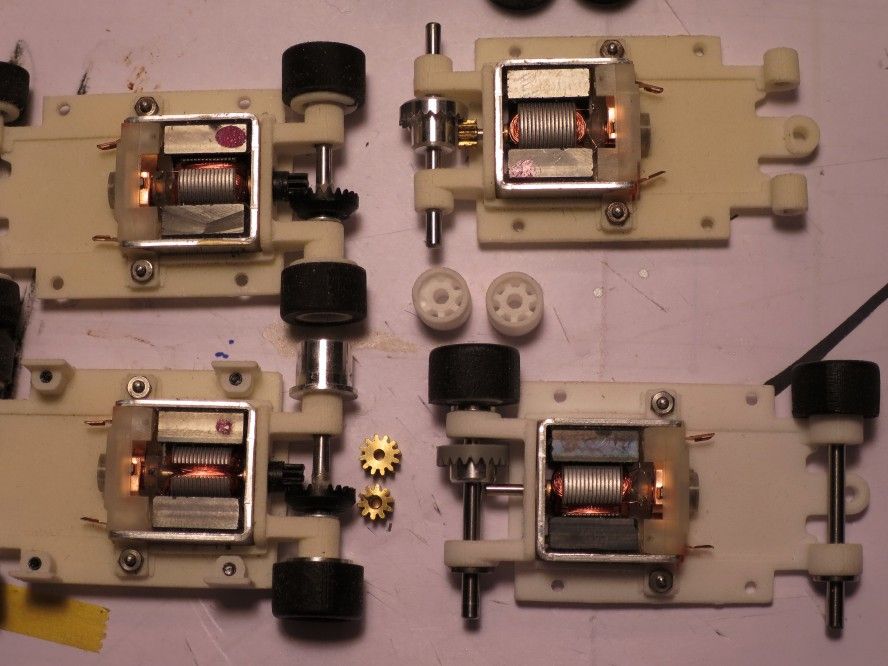

​i wanted the printed chassis as a fast to assembly backup for the scratchbuilt chassis. seem my measurement are leaking accuracy ...

​

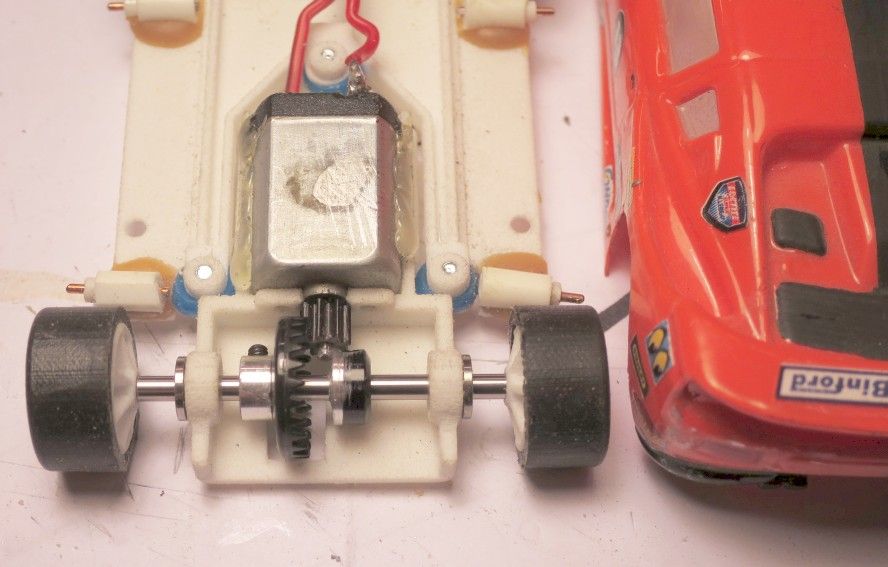

​Making rings to be placed between the chassis parts instead of the hard printed ones. First i used silicone material used for baking. the rings are now made out of latex - much softer. Anxious to try these out on the track!

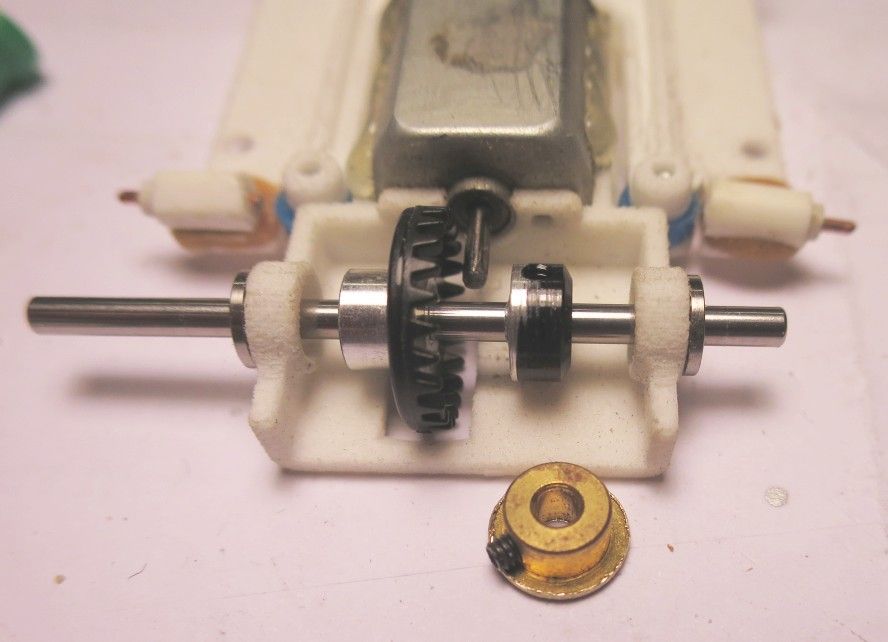

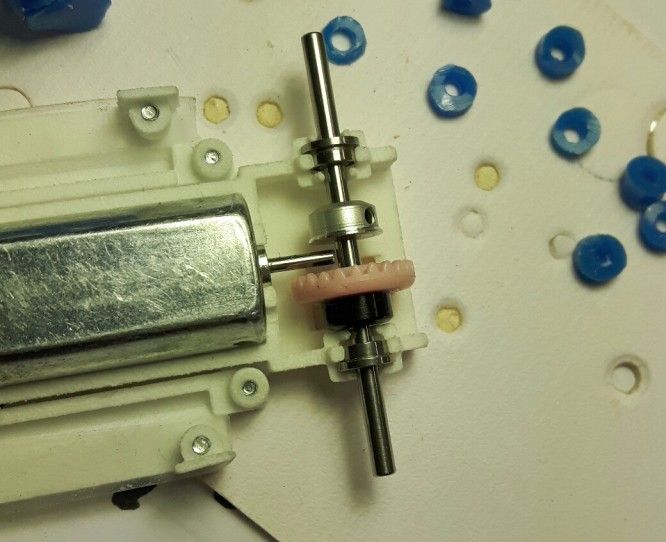

the centering from slot.it is made for 2mm motor axles and much too big for 1/43rd.

trimming the half off and sanding down the flange, with the dremel in the vise.

​

​much better now ...

​

​.

.

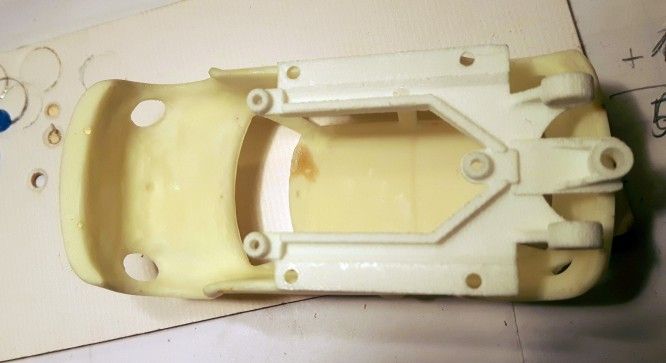

preparing the printed wheels - the previous printed wheels were quite fine in the tolerance. This time the axles hole have been to tight, due to the printing process. drilled out by hand, starting with 2mm, than 2.1. pushing the 2.2mm drill bit through without turning it. When it was through for the whole length i started to turn the drill bit. this gives a nice hole.

On my first try, I started turning the drill bit from the start. In this way, i got an angled axle hole and had to throw away the rim. Pushing the drill bit through and starting to turn it afterwards gives very good results, so.

​

​

​

​ ​

​ ​

​