I believe in declaring victory in small increments and if the later steps in brass chassis building are anything like the early steps, then those increments are going to get really small...........!

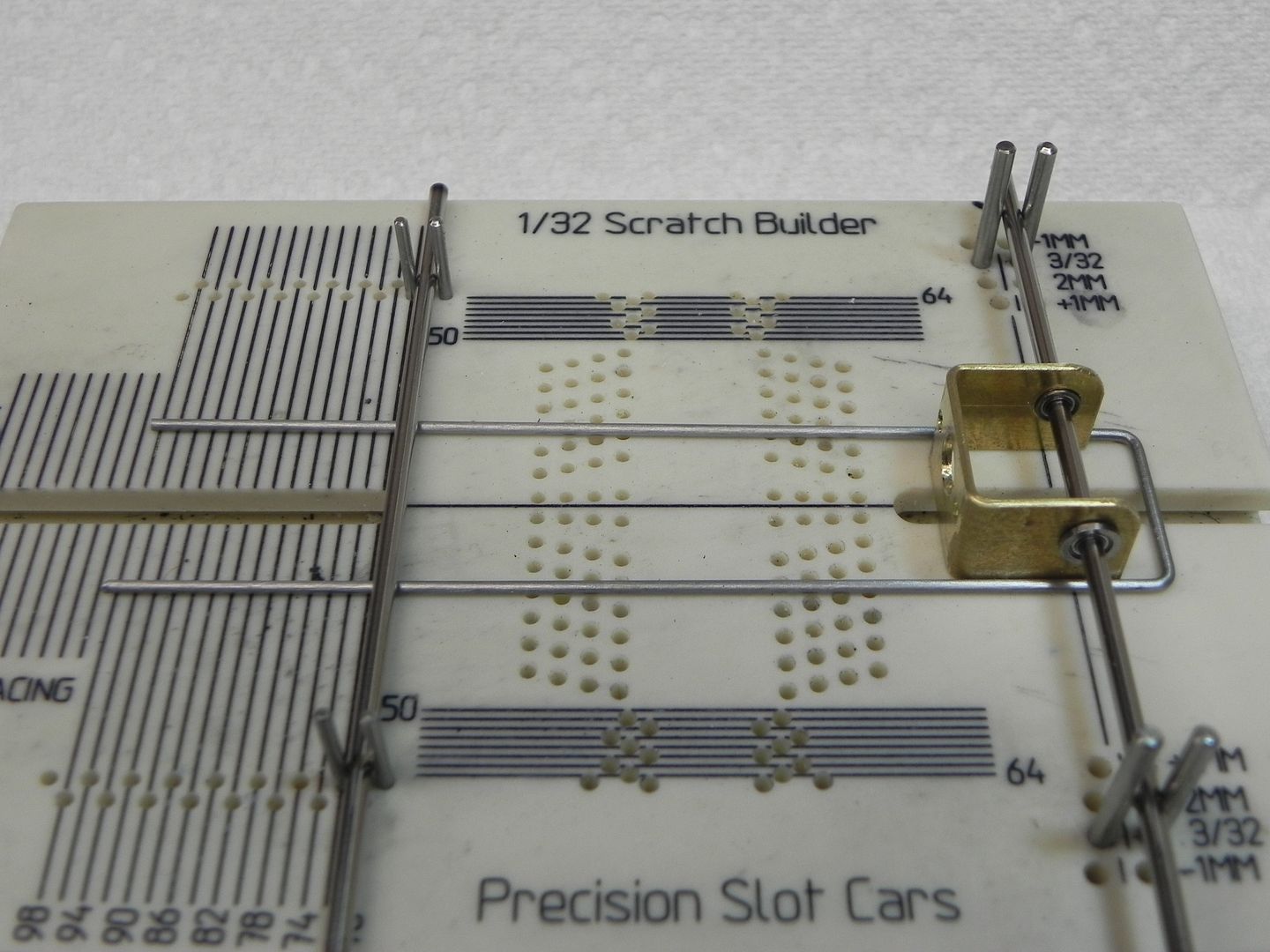

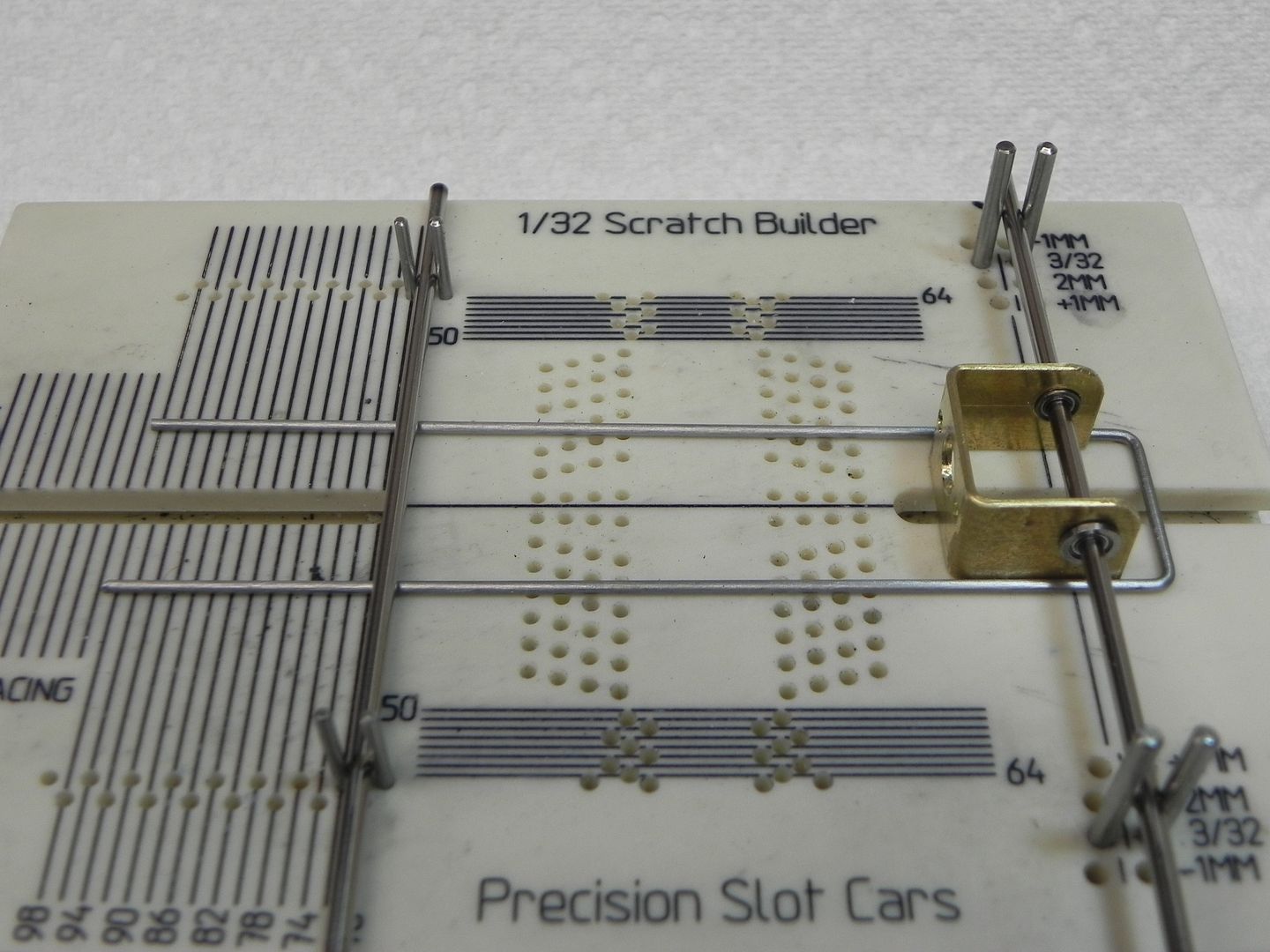

Today was "learn how to bend piano wire" day. The pic below shows the main rail; which is a two-sided box bend in a piece of 0.055" piano wire. Not a lot to show for a mornings' work, but a step ahead nonetheless:

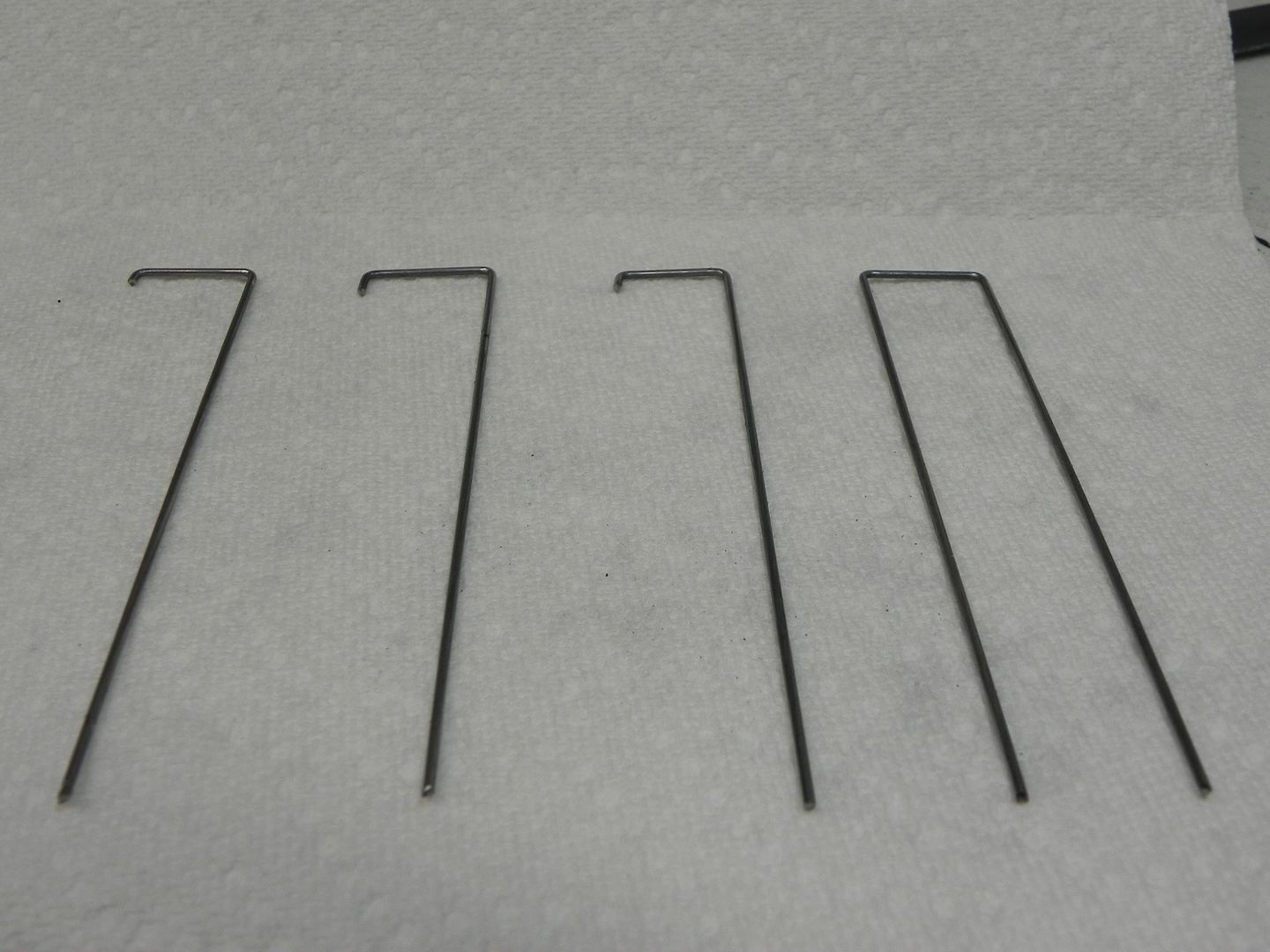

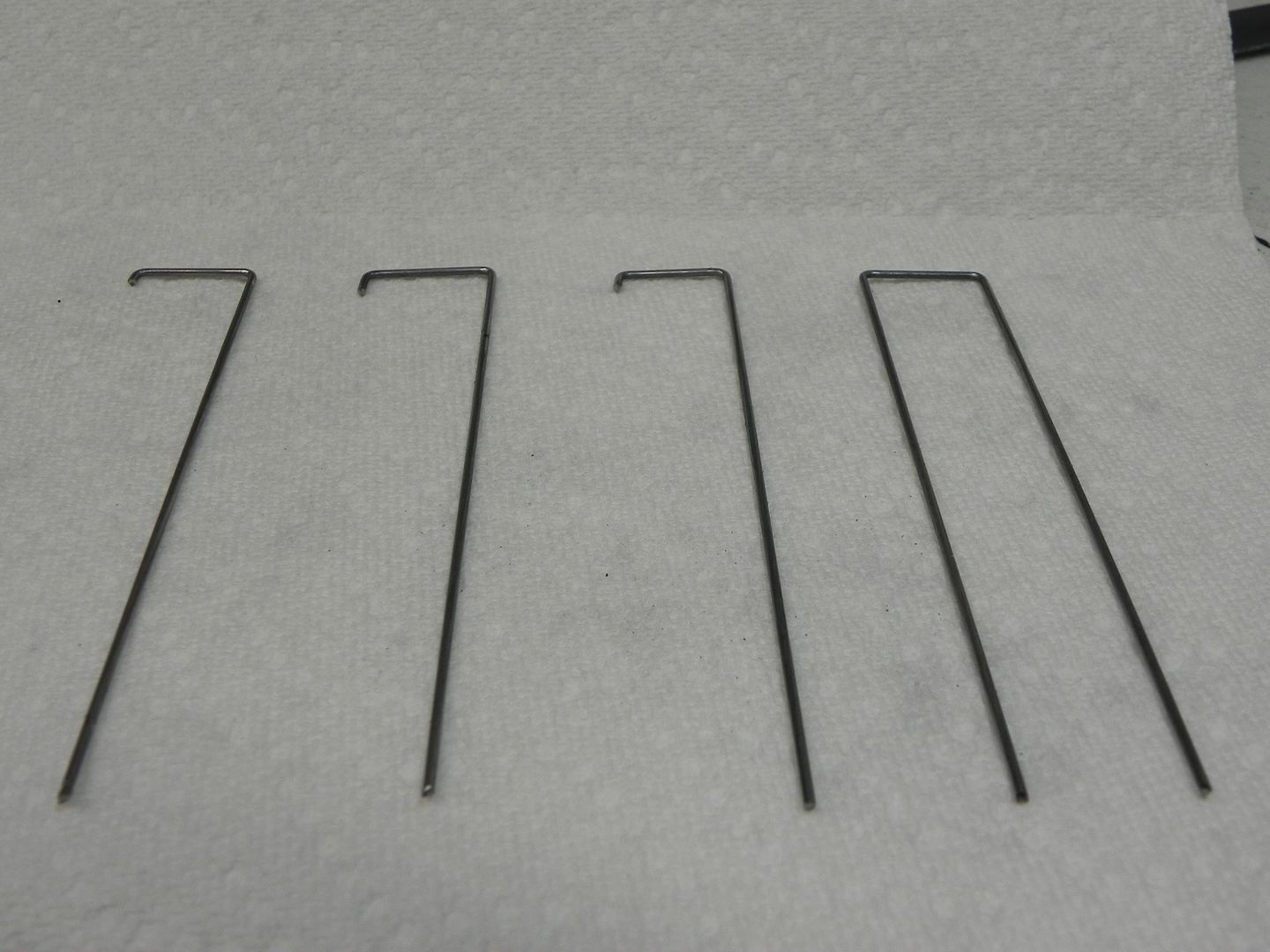

Leading up to that, was a series of "learning pieces":

Fortunately, you can save yourself a little material, by cutting-off close to the faulty bend..............good thing to know.............

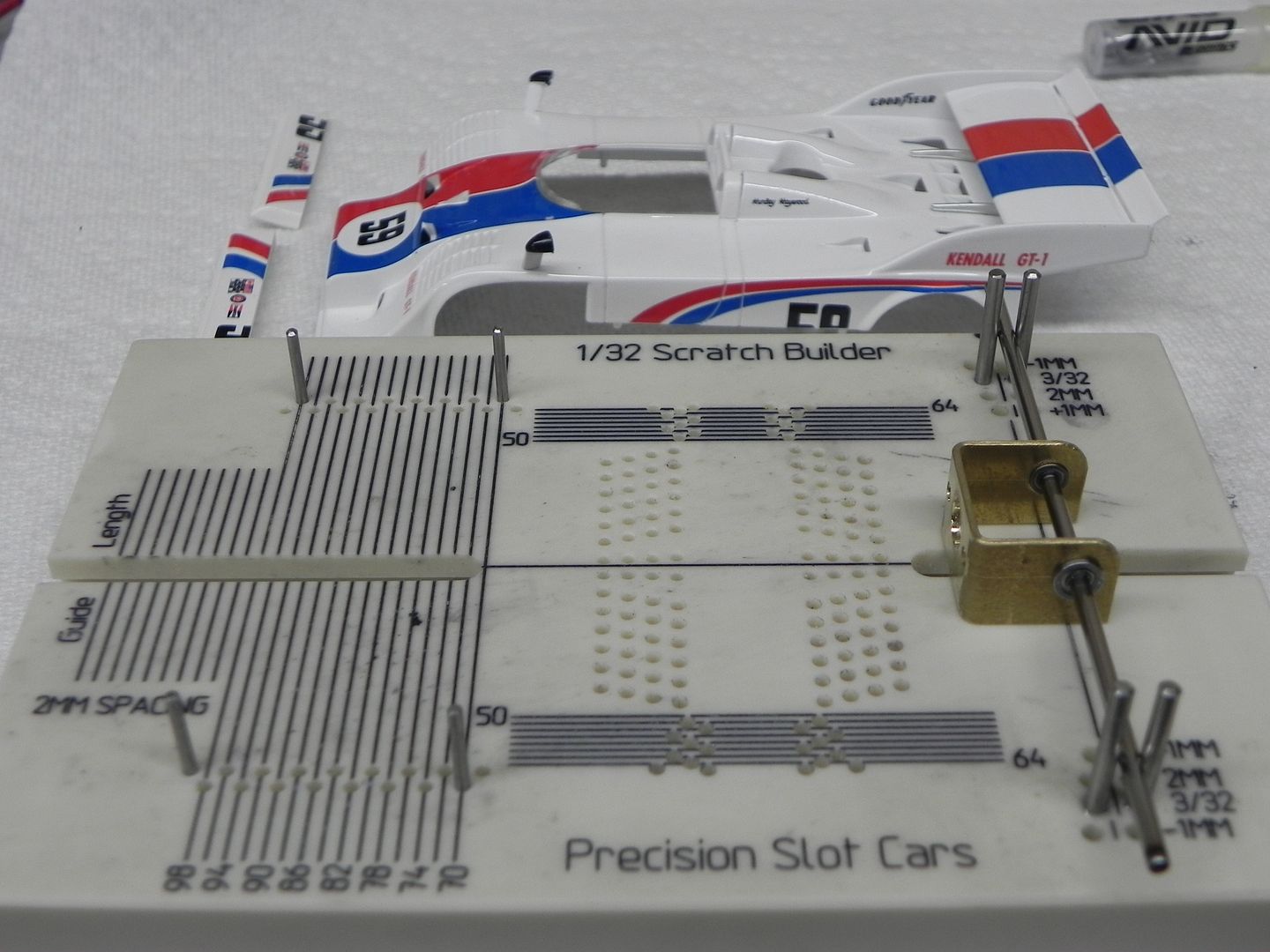

The rockers are back on the body now and I can see (imagination is a great thing!) the car starting to take shape:

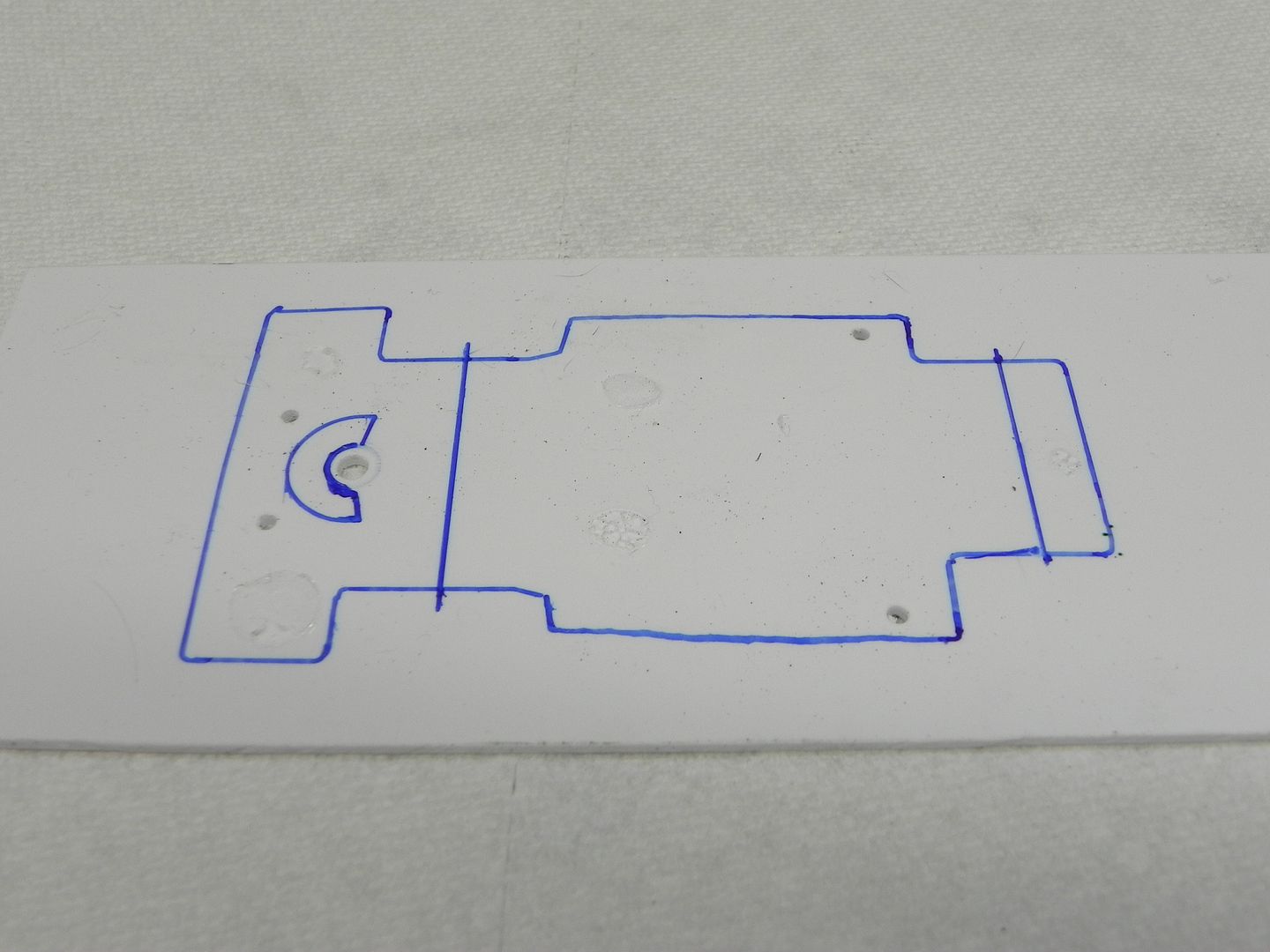

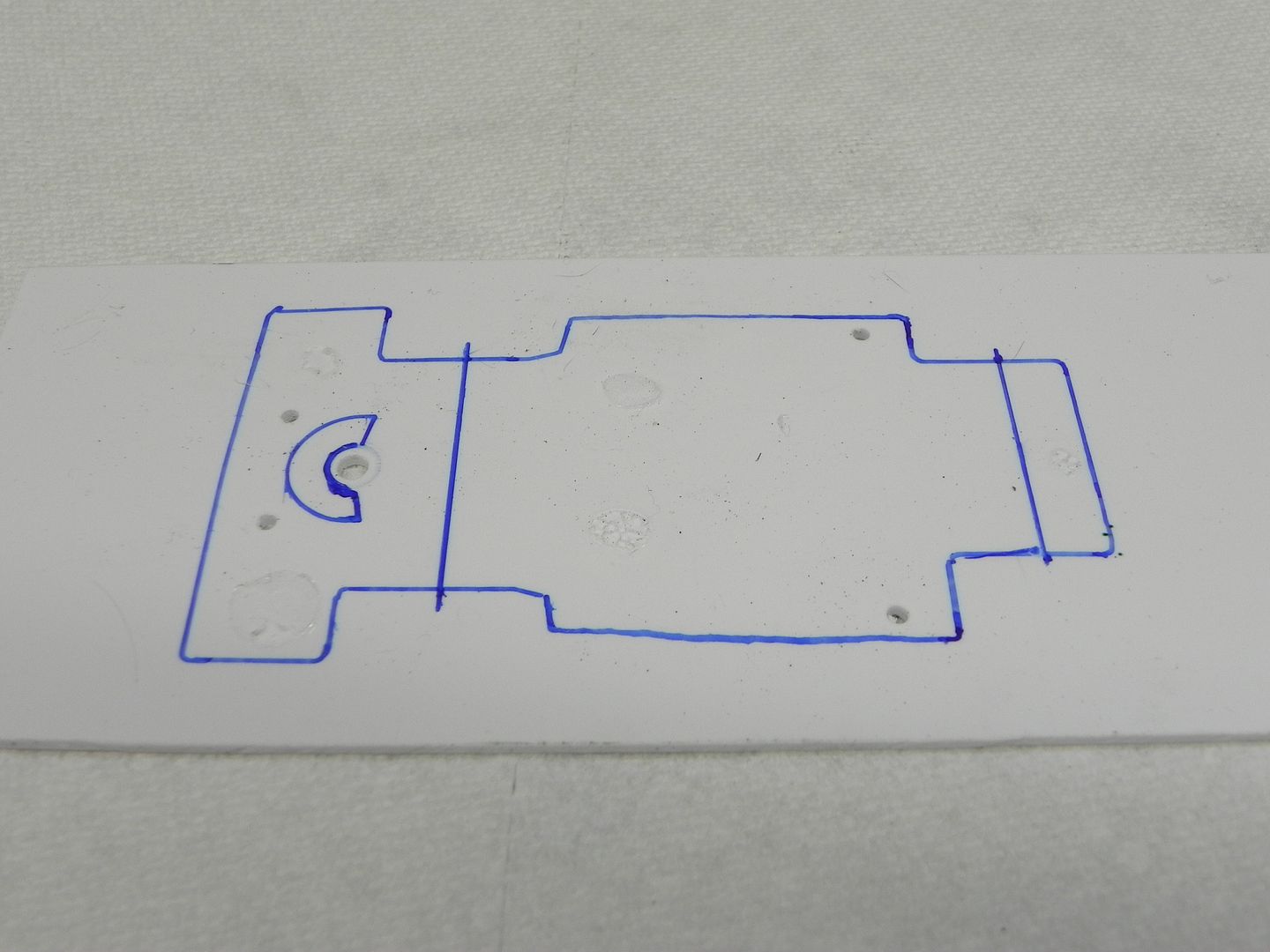

I also made up a template out of 2.0mm styrene, to lift chassis measurements and to help with the dimensions of the side pans/guide tongue placement/body post attachment points:

It's traced from the portion of the stock chassis that was left over once I had cut off the rockers. I have some visible motor parts in the back that the 917/10 needs to show, so I'll need some sort of shelf to allow for the attachment of those parts.

On to the cutting of some of the central brass pieces............rear motor mount platform, front body post attachment, front axle/guide tongue, etc. Then the side pans, then................

Inching along.................... :lol:

Allan